Insulation of the ceiling in the bath. How to insulate the ceiling in a bath with a cold roof Insulation of the ceiling of a bath with mineral wool instructions

It's frosty outside the window, but it's warm in the bathhouse. The temperature in the steam room is under 80 °. How to create optimal conditions for keeping warm, because it is known that hot air tends upward. Up to 40% of the heat goes through the ceiling, so its insulation is a fundamental point in the construction of an effective bath. It is especially important to arrange the ceiling of the steam room and seal the chimney.

The choice of insulation

What is important to consider when insulating the bath ceilings. It is necessary to exclude the presence of cracks and gaps, perform vapor barrier, choose the right material for thermal insulation. All this is necessary to create a reliable barrier to heat loss and prevent the formation of condensation.

Important! Condensation formed in the insulation layer destroys it, significantly reduces its service life, quality interior decoration and the service life of the entire structure. Vapor barrier materials selected correctly exclude such phenomena. Insulation is useless without proper ventilation and vapor barrier.

The use of natural insulation is the main condition for safety and environmental safety, not to mention the discomfort that occurs during evaporation chemical substances.

Styrofoam, polystyrene, mineral wool based on phenols are not suitable for bath insulation. But mineral wool made of dolomite fibers is quite suitable for these purposes. We choose from those materials that can withstand heating within 100 °. The best choice:

- glass wool, without any impurities, clean glass wool, the one used on heating mains, is not suitable;

- vermiculite made as a result of high-temperature processing of crystals;

- felt, natural, not synthetic, without binding threads, its resistance to high temperatures is record;

- expanded clay, bulk material, its disadvantage is its impressive weight.

- linen material is one of the most environmentally friendly, is a natural antiseptic, has a special strength, is durable;

- ecowool, a material made from recycled cellulose and wood fiber, to which antiseptic materials are added, is absolutely non-flammable.

- basalt wool, it does not burn, goes to the lining of the chimney.

The list will not be complete without mentioning the good old-fashioned methods, including:

- sawdust, clean, without debris and rot, medium size fractions, in order to exclude rotting, it is useful to mix them with ash;

- clay, environmentally flawless, not subject to decay, mixed with straw, is an ideal option for thermal insulation, there is one drawback - perhaps in a month, one and a half months, cracks may form in it, and the coating will have to be restored;

- moss, the ideal option, except that it is difficult to find such material.

It is better to build a bathhouse with an attic room, it is convenient to mount the ceiling cake from below and above, natural ventilation is available, finally, in summer, the net of the best room for drying brooms, in a bathhouse with flat roof all this is deprived.

Important during installation brick bath special attention should be paid to sealing the beams, no matter how the ceiling slab is mounted, residual condensation will occur, in order to preserve the beams, good sealing is needed.

Ceiling arrangement technology

A large temperature difference requires a certain thickness of the insulation layer. For middle band the thickness of glass wool, vermiculite should be at least 35 cm, expanded clay should be poured 60 cm thick, the optimal felt thickness is 45 cm.

It is necessary to lay out the insulation in a continuous layer, excluding gaps, poorly joined edges. Compliance with the recommendations for the thickness of the insulation layer will lead to the fact that the logs will be completely closed, which is correct.

How to make a ceiling cake.

- First, a vapor barrier is laid, its layer should hug the lags, it is better to fasten the fabric with a stapler, you cannot completely close the lags. Foil or material with a foil layer is attached to the ceiling boards, here it is important to monitor the 10cm overlap, which is fixed with aluminum tape.

- Insulation is placed on top of the vapor barrier layer, as a rule, the gaps between the logs are closed with layers of material,

- Next, they put waterproofing and if walking in the attic is supposed to, arrange a flooring, a counter lattice with a ventilation gap.

The ceiling is then sheathed with clapboard, the boards are attached to the logs.

Important! Glass wool is covered with a special membrane to prevent the scattering of fibers, cover expanded clay with newspapers and sprinkle with sand on top so that cold bridges do not form inside.

The insulation technology guarantees the duration of the bath's operation, reduces fuel consumption, and reduces the time for heating and heating the premises.

Steam room ceiling

The principle of the ceiling arrangement in the steam room is the same.

- First, lay aluminum foil, you cannot use foil materials based on expanded polypropylene.

- Then you should carefully close up all the joints, eliminate the existing gaps, tape will help.

- The next element of insulation is basalt wool, glass wool, which is laid in three layers between the beams.

- then the vapor barrier is laid, it will absorb moisture, will not let it into the insulation layer

- The last stage will be the installation of boards from the attic side and clapboard sheathing, which should be sewn onto the slats, which will provide a 5-10 cm gap for air exchange.

Important! It is good to check how well the ceiling is insulated in winter. Climbing up to the attic, you can see streams of warm air. Conduct an audit in these places. The absence of such streams indicates a high-quality insulation of the ceiling and, accordingly, the work of the steam room.

When designing a bath, it will be useful to lay the ceiling height from 2.1 to 2.3 meters. This is the optimal height, the higher, the more difficult it is to warm up and keep warm.

How to properly insulate the space around the pipe?

Wooden ceilings are highly flammable, so the pipe should be placed between the beams, preferably in the middle. It is a good idea to familiarize yourself with the rules against fire safety, proceeding with the arrangement of the chimney. The distance from the pipe to the tree must be at least 380mm.

So that the chimney opening is not too large, an element such as a ceiling unit is used, which creates an air gap between the heat-insulating material and the iron of the pipe.

Next, a heat-reflecting screen is installed, this is a stainless steel sheet, in the inner part of which there is a layer of refractory insulation, stone basalt wool. It all looks like a box around a pipe. A box is made of non-combustible materials, heat-resistant magnesite plates.

After installing the box, the space around the chimney is filled with basalt wool. Then a sandwich pipe is mounted, a part of the chimney extending onto the roof.

Important! Use a sandwich pipe equipped with a spark arrester. This design is somewhat more expensive, but it guarantees a wooden bathhouse from fire.

In general, from the pipe to the insulation should be at least 25 cm. You can fill up the cracks with clay or cement, because tightness is the main condition for heat conservation.

Russian bath - a unique place for taking relaxing and healing water treatments and communication. Strong immunity, beautiful skin and a body free from toxins - these are the results of a constant visit to the bath. However, the effectiveness of bath procedures cannot but depend on the quality of the bath insulation.

Everyone has long been accustomed to the fact that it is necessary to insulate the internal surfaces (floors, walls, ceilings) in apartments and houses. However, high-quality bath insulation is no less necessary. If it is enough to insulate only the walls in the apartment, then the bath and a private house need careful insulation of the ceiling. The thing is that the heated air becomes lighter and rises up. If the ceiling does not have good thermal insulation, then hot air will pass directly to the roof and will heat the air around the house, and this is an empty waste of heat.

Technology

Mineral wool is necessary be sure to isolate from water vapor... To do this, it must be closed with a vapor barrier, which must be airtight and waterproof. Today, foil glued at the joints with aluminum tape is often used for vapor barrier. Among the novelties of the construction market is folgoizol, modern material, made on a fiberglass basis. In addition, glassine, membrane insulation or ordinary plastic wrap are often used.

Mineral wool is necessary be sure to isolate from water vapor... To do this, it must be closed with a vapor barrier, which must be airtight and waterproof. Today, foil glued at the joints with aluminum tape is often used for vapor barrier. Among the novelties of the construction market is folgoizol, modern material, made on a fiberglass basis. In addition, glassine, membrane insulation or ordinary plastic wrap are often used.

Bath ceiling can be:

If the ceiling is hemmed, that is, the boards are hemmed to the floor beams, it is necessary to insulate from the side of the attic. 2 layers of vapor barrier (glassine, roofing material, etc.), a layer of mineral wool, again a layer of vapor barrier are placed on the ceiling.

In the case of a panel ceiling, each panel is covered with a vapor barrier film, mineral wool is laid on it and closed with a vapor barrier. All this is sewn up with boards.

The easiest way to insulate a floor ceiling... The technology here will be the same as in the case of a false ceiling. For this, a vapor barrier is rolled out on the boards from the attic, then a layer of mineral wool 200-250 mm thick is placed on it and completely covered with a vapor barrier. Then the floor is sewn up with boards.

Pros and cons

Among the advantages of mineral wool insulation you can call what:

Among the advantages of mineral wool insulation you can call what:

- this material almost does not conduct heat and can insulate a room well, including from extraneous sounds;

Everything has its downside, and mineral wool as a material for warming the ceiling of a bath, unfortunately, is no exception. It has few disadvantages when compared to the number of advantages, but these disadvantages are very significant... Consider them:

- mineral wool cannot be crushed or tamped, because compacted fibers greatly lose their thermal insulation properties;

Technology of thermal insulation of the ceiling of a bath with mineral wool

Mineral wool is one of the most inexpensive and reliable materials for insulating the ceiling of a bath. The insulation technology is quite simple, and even a non-professional can handle it.

Thermal insulation of the ceiling of a bath with mineral wool: instructions

Since heat loss through the roof can be from 25 to 40%, thermal insulation of the bath ceiling with mineral wool is an important stage in the construction of a steam room. In the cold season, the stove will not be able to maintain the temperature at the desired level if the room is not insulated. Condensation on the ceiling will gradually destroy the ceiling. To prevent this, it is necessary to insulate the ceiling with mineral wool from the inside or from the attic.

Since heat loss through the roof can be from 25 to 40%, thermal insulation of the bath ceiling with mineral wool is an important stage in the construction of a steam room. In the cold season, the stove will not be able to maintain the temperature at the desired level if the room is not insulated. Condensation on the ceiling will gradually destroy the ceiling. To prevent this, it is necessary to insulate the ceiling with mineral wool from the inside or from the attic.

In the presence of the right tools and materials, all work can be done independently. The main thing is to follow all the recommendations and instructions. Thermal insulation can be made with different heaters. One of these is mineral wool, the features of which will be discussed later.

Insulation overview

Very often, to insulate the ceiling in a private house, mineral wool is used. This is due to the value for money. For a low cost, you can get a material with low thermal conductivity, the installation of which is not very difficult to do with your own hands. Mineral wool consists of blast furnace slag, glass, sand and rocks. Synthetic resins act as a binder. Minvata is of several types:

- slag;

- glass wool;

- basalt wool;

- ecowool, or cellulose.

To know how to properly insulate the ceiling, you need to understand which material is better to choose. The first type tends to quickly absorb moisture, so its use in a bath is impractical. High hygroscopicity leads to loss of thermal insulation properties. Brittle and prickly slag fibers do not allow using it indoors. Its only advantage is its low price.

Insulation of the ceiling with glass wool is possible, but undesirable. It is a fused glass from which thin fibers are drawn. Like slag, they are fragile. Contact with human body may cause irritation of mucous membranes or skin. This material should be used for thermal insulation from the attic, but not from the inside.

Insulation of the ceiling with glass wool is possible, but undesirable. It is a fused glass from which thin fibers are drawn. Like slag, they are fragile. Contact with human body may cause irritation of mucous membranes or skin. This material should be used for thermal insulation from the attic, but not from the inside.

When insulating the ceiling in a private house with mineral wool, as a rule, they use basalt or stone wool. Since it is made from gabbro-basalt, it has plastic fibers. If the thickness of the insulation is less than 10 cm, it is sold in rolls. When the parameter is more than 10 cm, then plates or panels are formed. They have high strength and come in different densities. Basalt wool can be used to insulate a room from the inside and outside.

Some manufacturers make panels with a foil layer. If you turn this side of the thermal insulator into the room, the heat will be reflected from the surface and return to the room. This will help to keep the warm air inside.

Ecowool is 80% cellulose, therefore it is considered environmentally friendly. So that the material is not subject to destruction by various bacteria, and in order to reduce flammability, boric and brown acids are added to the thermal insulator. The first protects the insulation from decay, microorganisms and rodents. Brown acid is a fire retardant, therefore its use reduces fire hazard.

All types of cotton wool are highly hygroscopic. However, insulation of the ceiling with ecowool is preferable. This is due to the fact that it is able to absorb a large amount of moisture without significant deterioration in thermal insulation properties. Minplate will lose 9% in the coefficient of thermal conductivity with an increase in humidity by 1-2%. Ecowool will add only 2-5% in thermal conductivity with an increase in humidity by 25%.

Thus, insulation of the ceiling in a wooden house with mineral wool is less preferable, since cellulose wool maintains the air inside the room in a comfortable environment without compromising the thermal insulation properties. Since the installation is not very difficult, you can do it yourself with ecowool.

The disadvantage of mineral wool is the binder. Resins release chemical compounds into the air that can be harmful to humans. And for laying ecowool, you need to use special equipment.

Vapor barrier and waterproofing

Insulation of the ceiling in a bath with mineral wool cannot be carried out without vapor barrier work. As the warm air rises to the ceiling, it penetrates under the skin and turns into condensation on the insulation. And this reduces the thermal insulation properties of cotton wool and contributes to the appearance of fungi and mold. The vapor barrier is designed to protect the insulation and wooden floor beams from moisture. It is better to lay foil film in bath rooms.

Waterproofing will help protect the insulation from moisture from the attic side. The roof may leak or condensation may form in the attic. And so that the insulation does not come into contact with moisture, it is covered with a waterproofing film. To do this, use ordinary plastic wrap, roofing felt or special materials. It is necessary to overlap the steam and waterproofing, and glue the joints with ordinary or reinforced tape.

Insulation technology from the attic side

Mineral wool comes in different thicknesses, and climatic conditions are the determining factor. The thickness of the mineral wool for insulation of the ceiling must be at least 10 cm. It is laid between the battens in the spacer.

Mineral wool comes in different thicknesses, and climatic conditions are the determining factor. The thickness of the mineral wool for insulation of the ceiling must be at least 10 cm. It is laid between the battens in the spacer.

Insulation of the attic floor with mineral wool begins with the fact that boards are hemmed to the beams. Thanks to this, the insulation can be positioned between the ceiling. If the height of the beams is not enough, the slats are fixed on them. The layer of mineral wool should be slightly less than the width of the slats.

Then the beams, slats and the space between them, in which the heat insulator will fit, is covered with a vapor barrier film. It must be laid with an overlap so that the edges overlap each other by 10-15 cm. The instructions for insulation work provide for sealed layers of hydro and vapor barrier. Therefore, all joints must be glued with construction tape. The material can be attached to wooden partitions with a stapler.

Further, mineral wool is laid in the space between the slats. In order for the thermal insulation to be performed with high quality, the plates must be tightly fitted to each other. Even small gaps will result in heat loss.

When the heaters are laid, they proceed to waterproofing. An overlap film is laid on top of the cotton wool. The edges should also go 10-15 cm on top of each other and be glued with tape. At the end of the work, a plank covering is laid on top. Thus, the attic floor is insulated using wooden beams.

Thermal insulation from the side of the room

It is also necessary to consider how to insulate the ceiling in a bath with mineral wool from the inside. With this method of thermal insulation, it is better to use stone wool... Before insulation from the attic side, floor beams are laid waterproofing material... A plank covering is laid on top of it.

It is also necessary to consider how to insulate the ceiling in a bath with mineral wool from the inside. With this method of thermal insulation, it is better to use stone wool... Before insulation from the attic side, floor beams are laid waterproofing material... A plank covering is laid on top of it.

After that, the insulation of the ceiling with mineral wool will be carried out indoors. The heat insulator is placed between the beams. If their width is not enough, the slats are additionally attached. The distance between the beams should be 3-4 cm more than the width of the insulation plates. This is necessary in order for the panels to stand up.

How to insulate the ceiling with mineral wool in an already built bath? To do this, you need to fix the guides to the ceiling. The first step is to mark them using a building level. Mark the lines along which the guides will be set. The distance between the slats is adjusted to the dimensions of the insulation plates so that the material is tightly fixed between the guides.

The wooden frame is fixed with self-tapping screws every 50-60 cm. The metal slats are attached to special suspensions. With their help, you can adjust the distance to the ceiling and fix the insulation with bent parts, which does not hold tightly.

When the laying of the mineral wool is completed, they begin to vapor barrier. Installation instructions provide for a sealed coating. For this, the canvases must be overlapped and the joints must be glued with tape. Then, on top of it, wooden slats are attached to the beams. Decorative lining will be screwed to them.

Only the correct fulfillment of all conditions will ensure high-quality thermal insulation of the room. However, if you are in doubt about how to insulate the ceiling in the bath with your own hands, or are not sure of your skills, it is better to seek help from professionals.

Thermal insulation of the ceiling of a bath with mineral wool: instructions

Since heat loss through the roof can be from 25 to 40%, thermal insulation of the bath ceiling with mineral wool is an important stage in the construction of a steam room.

Insulation of the ceiling in the bath with mineral wool

When building a bath with your own hands, one must not forget about the need to insulate the ceiling, otherwise all the heated air will evaporate outward and the bath will quickly cool down. Warming is carried out today different materials, but one of the simplest and most inexpensive options is to use mineral wool. In this article, you will learn how to insulate the ceiling in a bath do it yourself with mineral wool so that in winter time take a steam bath for pleasure.

How to properly insulate the ceiling in a bath

Minvata afraid of moisture, so it must be isolated from all kinds of fumes. For this, the insulation is closed with a waterproof sealed thermal insulation. For vapor barrier, foil materials are best suited, which are glued with aluminum tape at the joints. Folgoizol has a fiberglass base and guarantees high-quality insulation. You can also use membrane insulation, glassine or plastic wrap.

The bath can have the following types of ceiling, which can be insulated with mineral wool:

- Grazing

- Panel

- Hemming

In the false ceiling, the boards are mounted to the ceiling beams. Mineral wool insulation should be done from the attic side. Any vapor barrier is placed on the ceiling in 2 layers, on top there is a layer of mineral wool, and then another layer of insulation. The seams in the bath are glued with foil tape. The flooring is made of boards for the vapor barrier.

Insulation of the floor ceiling in the bath do it yourself is considered the simplest. A vapor barrier is spread from the attic side. Then comes the mineral wool, about 25 centimeters thick. From above, everything is closed with a vapor barrier and boards. For a panel ceiling in a bath, the panel is covered with a film, mineral wool is laid on the vapor barrier, everything is covered with another layer of film and sewn up with boards.

Advantages of mineral wool for warming in a bath

Minvata practically does not conduct heat, it is safe and environmentally friendly, while it allows you to isolate the room from extraneous sounds. Another advantage of mineral wool is that insects, rodents do not start in it, it does not rot, it is not subject to mold.

Mineral wool as a heater in the bath easily transfers mechanical loads and is durable. This insulation material is fireproof, easy to fit and has a long service life. During installation, it must not be tamped and creased, as this affects the quality of thermal insulation. All kinds of water evaporation must be excluded, as this leads to a deterioration useful properties mineral wool.

The technology of laying mineral wool for a bath is quite simple and does not require specialized skills. The insulated sauna is guaranteed to keep warm for many years, so you can enjoy visiting it with the whole family or with friends. Study on our website and make repairs in the bath and country house yourself.

How to insulate the ceiling in a bath with your own hands with mineral wool

The best materials for insulation wooden bath in the country. Advantages of mineral wool as insulation for an attic, steam room, country house ...

Thermal insulation of a bath with mineral wool

Those who have their own sauna know how much energy must be consumed in order to reach the desired temperature in the steam room. In order to save money and time, every effort is made to make the most of the heat generated. For this purpose, the ceiling, floor and walls of the bath are insulated with mineral wool. This material is not afraid of high temperatures, it is non-toxic and it has a rather low coefficient of thermal conductivity.

How to insulate a bath: inside or outside?

External insulation without a ventilation gap is bad.

To begin with, let's figure out when it is required to insulate the bath from the inside with mineral wool, and when outside. There is such a science of heat engineering, it studies the theory of the use of thermal energy in residential and non-residential premises. On the basis of this knowledge, certain methods are adopted to reduce heat loss in practice. So, according to the principles of heat engineering, insulation should be carried out outside. Thanks to this approach, the dew point is shifted into the thermal insulation layer, where there are no conditions for condensate to settle.

Therefore, if there is a technical possibility, then the mineral wool for the bath should be laid outside. This applies to both the steam room and the rest of the premises. If this option is not suitable or impossible in execution, then you can install the insulation from the inside. By the way, in steam rooms this is most often done. This is due to the cost of the work.

When insulating a bath from the inside with mineral wool, you save on exterior decoration building. In one of the articles we told how to insulate walls with mineral wool outside... In short, there are two techniques:

- ventilation facade - siding is laid as a finish;

- wet facade - mineral wool is plastered in two layers.

Regardless of which side you put the insulation on, from the inside of the room you still need to make a crate, put a vapor barrier and sew it all up with clapboard. By putting the mineral wool on the inside, you save on the cost of the outer sheathing, finishing (siding or plaster) and work.

In fact, installing a heated towel rail with your own hands is a fairly simple procedure if you know how to pack the threads.

In fact, installing a heated towel rail with your own hands is a fairly simple procedure if you know how to pack the threads.

In this article we talked about how a heated towel rail works in a bathroom.

How to choose a vapor barrier

Penofol is used as a vapor barrier for a bath.

Using mineral wool for a bath, you need to take into account its tendency to saturate and retain moisture. Having got wet, the insulation ceases to be such, and instead of containing the heat, it begins to intensively remove it outside the room. It should be borne in mind that in a steam room the humidity is very high and steam can penetrate into the thermal insulation, even if it is laid outside. At the same time, the wall will also get wet, which is also extremely undesirable. Therefore, the vapor barrier must be installed from the inside of the room onto a previously erected crate.

In principle, any roll material with vapor barrier characteristics is suitable that meets the following requirements:

- non-toxicity;

- strength;

- resistance to high temperatures.

Most often, foil materials, for example, Penofol, are used as a vapor barrier for a bath. It is a two-layer material that consists of a polyethylene foam cushion and a layer of aluminum foil. it reflective insulation, which beats off up to 97% of IR rays, which is especially important in the steam room itself. At the same time, one should not exaggerate the reflective effect of Penofol, and even more so if its installation is performed incorrectly. By making a mistake, you will only increase the heat loss.

The simplest air recuperator for an apartment is installed directly in the wall. It is able to provide oxygen flow in a small room.

The simplest air recuperator for an apartment is installed directly in the wall. It is able to provide oxygen flow in a small room.

Mineral wool installation methods

The counter grill is packed over the vapor barrier on all work surfaces.

We will consider baths with beamed ceilings, since this is the most common design. You will rarely find a sauna with concrete ceilings... Let's divide the editing into two groups:

As we have already said, the mineral wool for the sauna can be laid on the walls from the outside and from the inside. Methods outdoor insulation of the house we have already covered, so we will focus on internal works... Moreover, it is cheaper. First, we select the cross-section of the bars for the future crate. The height of the timber should be such that the mineral wool is flush, or even more. The step between the guides is three centimeters less than the width of the insulation. The bars are mounted perpendicular to the floor.

Mineral wool is placed between the guides. On top of the lathing with a stapler, Penofol is attached with foil inside. The vapor barrier tapes should not overlap, they should be placed butt-to-end. The joints must be glued with aluminum-coated tape to create a monolithic mirror. A horizontal counter-lattice is stuffed on top of the vapor barrier, which is then sewn up with clapboard.

Penofol on the walls, floor and ceiling must be connected to form an airtight protective layer, like in a thermos.

Insulation of the ceiling in the bath with mineral wool and the floor can be combined, since the technique is almost the same. In both cases, the insulation is placed on the rough floor:

- on the rough floor from the inside;

- on the rough ceiling - outside from the attic.

There are no subtleties here, you just need to lay the required layer of mineral wool flat. Next, it's up to the vapor barrier, which is always placed between the insulation and the heated room. On the floor, Penofol is placed on top of the mineral wool, the joints are glued and a counter lattice is packed for a finishing coating. With the ceiling, things are different, since it is necessary to protect not only thermal insulation from moisture, but also load-bearing beams... Therefore, penofol is attached to the rough ceiling from the inside with a shiny side in the middle of the room. All this is sealed and a counter-lattice is stuffed for further finishing.

Why do you need a counter grill

As you may have noticed, on all surfaces a counter grill is stuffed on top of Penofol. It is needed so that the buffer air zone remains, which performs two functions at once:

- enables foil to beat off infrared rays;

- prevents condensation from absorbing into the finish.

So that Penofol can beat infrared rays there must be an air gap of at least 15 mm, since infrared radiation is transmitted only through the air. When the foil touches the finish, heat is transferred directly from one material to another. In this case, aluminum will only accelerate the heat transfer reaction, respectively, the heat loss will be more intense.

Thermal insulation of the ceiling of a bath and a sauna from the inside with mineral wool

Mineral wool is used to insulate the ceiling, floor and walls of the bath. It can be installed both outside and inside. A vapor barrier must be used in the sauna

High-quality thermal insulation is the key to the most comfortable and long-term use of the bath, as well as a guarantee that there are no additional costs associated with heating this room from the inside. Therefore, how to insulate the bath, namely the walls, ceiling and floor in it, is one of the most important issues. 4 main surfaces are insulated: roof, floor, ceiling and walls.

As part of this publication, we suggest that you familiarize yourself with the nuances of the process during which the thermal insulation of the bath ceiling is performed.

How walls are insulated is discussed in another article of our project. Consider the most important information about the insulation process, the properties of the available thermal insulation materials and instructions for performing the relevant work aimed at insulating the ceiling in the bath with your own hands.

- There are basically three reasons for such precious heat to escape from the room:

- The presence of cracks in the ceiling structures;

- Heat transfer to cold objects of the environment;

- Passage of heated air masses through all sorts of homogeneous / monolithic barriers.

To eliminate all of the above reasons, the bath is insulated by installing a multilayer structure on the floor, walls and ceiling, including, in addition to all other elements, an insulating layer of thermal insulation material. For a bath, the ceiling insulation is very important, and if you do not lay such material or lay it incorrectly, on the ceiling, or rather, on its floors (the material for which can be a maple beam), condensation will fall out, and much more time will be spent to warm up the room , and this, in turn, will cause an increase in the cost of consumed energy resources.

Note: the installation of each subsequent insulation layer must be carried out perpendicular to the previous one. This technique allows you to make the structure as reliable as possible and practically avoid deformation changes in the future.

Depending on the design features buildings, baths are divided into 2 groups: baths with an attic / attic and baths without them. Considering the question of how to insulate the ceiling in a bath, we will not describe this process for baths with an attic / attic floor due to its high cost. Regardless of whether the bathhouse has a second floor or an attic, or there is none, each of them requires high-quality and competent insulation from the inside and the question of whether the ceiling in the bath is to be insulated is the same for any configurations of baths.

Insulation and other materials

Regardless of which roof structure the bath is equipped with, in addition to the installation of insulation material, the vapor barrier of the bath ceiling is also performed.

The vapor barrier layer will not allow the resulting humid vapors to settle on the surface of the heat-insulating material.

This is all the more important, since the deposition of vapors on the heat insulator, followed by their condensation, provokes the accumulation of moisture from the inside of the insulation, and this has the worst effect on its service life and its quality.

Nowadays, it is possible to insulate the ceiling in a bath with your own hands using relatively budget materials. The same applies to vapor barrier. Here is a short list of how to insulate the ceiling in a bath:

- Wax paper;

- Clay (a 20 mm clay layer is applied to the ceiling boards from the roof side);

- Mineral wool;

- Compacted cardboard pre-impregnated with natural drying oil;

- Aluminum foil.

Now, let's take a quick look at the process of insulating a bath ceiling with two of the above materials.

Clay

Clay, as a heater, has such indisputable advantages as ease of preparation and laying of the material, low cost (or even free of charge, since clay can be found in nature), low thermal conductivity, absolute unattractiveness for insects and rodents, and high environmental friendliness.

As you can see, clay itself is already an excellent insulation for baths and saunas. And in combination with sawdust, which gives it porosity, while lowering the already very low thermal conductivity, clay does become a leader in all respects among not expensive heaters.

Red clay is considered the most popular as a heater.

It differs in plasticity and even hygroscopic. The very laying of the clay-sawdust mixture takes very, very little time. However, such a moist material needs to dry for about a month at above-zero temperatures.

To prepare a mixture of clay with sawdust, it is better to take coniferous or oak species, and before use they must certainly be thoroughly dried and treated with a fire retardant and antiseptic.

The resulting clay mortar should have a thick consistency. The approximate ratio of sawdust to clay should be 3: 2.

When the ceiling of the bath is insulated with clay and sawdust, it should be done in the following order:

- Using a construction stapler, waterproofing is attached to the ceiling ceiling;

- Over the waterproofing with a step of 300-400 millimeters, slats with a width of about 100 millimeters are packed;

- The clay is moistened and mixed with treated oak or coniferous sawdust. Stirring is carried out until a homogeneous consistency is obtained.

- The resulting mixture is placed in the cells formed by the slats until they are completely filled, leveled with a spatula and left until completely dry.

Mineral wool

Quite often, those who plan to insulate a bath room have a question: how to insulate the ceiling of a bath with mineral wool? Let's look at this question and try to answer it.

Mineral wool with a thickness of up to 50-100 millimeters is produced in rolls. Installation is carried out by unwinding these rolls, cutting sheets of mineral wool with an ordinary knife into pieces of the required length and laying the resulting pieces to the place of insulation. If the thickness of the mineral wool is more than 100 millimeters, it is produced in the format of mats, which, if necessary, are simply cut off and placed in the spacer between the rafters, logs or crate elements. In this case, it is quite possible to do without any additional fasteners. Mineral wool, among other things, is an excellent insulation for a frame bath.

If you cannot do without additional fastening, it can be done either with a rack crate, or with a strong nylon mesh, or with a construction stapler.

You can, of course, use and basalt insulation for a bath, which is based on either basalt wool, or the so-called basalt cardboard. However, the effectiveness of these materials is an order of magnitude lower than that of mineral wool. Also, basalt wool is less environmentally friendly.

If you need a better and more reliable vapor barrier for a bath, then here you should pay attention to modern factory materials. Here are the most popular options for such vapor barriers:

- Polyethylene film... Excellent waterproofing insulation for a bath, in the absence of other available options also used as a vapor barrier. In order for the condensate to evaporate, ventilation gaps must be allowed when fixing the plastic film;

- Steam insulation with lint. The basis of such an insulator is the same plastic film. The purpose of the villi is to retain condensed moisture. This is good for the level of the insulating effect;

- Membrane vapor barrier.

In addition to the above, there are universal and therefore more expensive hydro-vapor insulators. Although the cost of these materials is an order of magnitude higher, however, insulating the ceiling of the steam room with them will give more effective protection.

Film waterproofing is most expedient when we insulate the ceiling with expanded clay or mineral wool. The film, laid on top of these heaters, takes on the function of a moisture-proof coating, providing a high level of protection against moisture coming from the roof.

Using mineral foil wool as an insulating material, the installation of a ceiling in a bath can be done without laying a vapor and waterproofing layer.

When deciding how to insulate a sauna ceiling, floor or walls, you should definitely remember about fire safety. So, the distance between the chimney and flammable elements (for example, lathing made of wooden slats) should be at least 200-300 millimeters.

As additional measures, preventing fire, around the chimney pipe, you should build a box made of metal or some other non-combustible material to your taste. The inner cavity of the box should be filled with expanded clay or other non-combustible material.

With regard to the thickness of the thermal insulation layer: here everything is decided by climatic conditions on the one hand and the characteristics of the insulation material itself on the other. On average, this parameter varies within 150-200 millimeters, and changes in accordance with the above two factors.

How to properly insulate the ceiling of the bath or, more precisely, how to do it? There are several answers to this difficult, but very important question... You can use the "old-fashioned" methods, which imply the use of almost free, that is, improvised (or grass roots - clay, red moss, and so on) materials. But it is possible to use the achievements of our time, which are more effective, but also more expensive.

So that the insulation of the ceiling of the bath with your own hands does not become an unbearable task for you due to ignorance, we suggest considering a short list of insulation materials.

The so-called "folk" thermal insulation. A very outdated but still rarely used method in which warming the ceiling of the bath with clay and sawdust or with dry leaves, not from the inside, but from the outside, it is performed in the following sequence: the mint clay is laid with a layer of 2-2.5 centimeters; the previous layer is covered with sawdust and it is they who play the role of the main heat insulator. This method is quite popular, since using such, in fact, improvised materials allows you to perform insulation very, very inexpensively

The thickness of the sawdust layer is selected depending on climatic conditions in the location of the bath itself (usually 100-150 millimeters); the topmost layer of such a "sandwich" is a 100-150 mm dry earth mound. The effectiveness of this method is high enough and not expensive. However, its service life is an order of magnitude inferior to other available methods. It is for this reason that the insulation of the ceiling of the bath with sawdust will need to be repeated every few years.

Ceiling insulation in a bath with cold roof expanded clay. Expanded clay is not a very expensive material, which can be used to insulate the ceiling of the bath with your own hands without any problems. It is especially convenient in cases where a bath ceiling with a large coverage area is being insulated, and in order to save money spent, you have to decide how to fill the ceiling in the bath. In order to achieve an improved effect, the thickness of the expanded clay layer should be 300 millimeters or more. Can you make it thinner? This is permissible, but then the warming effect will no longer be so noticeable. Only then will the insulation of the ceiling with expanded clay be complete.

Expanded clay it is not friendly enough to moisture, therefore, it requires serious waterproofing. For proper protection of the expanded clay layer from moisture, it is recommended to lay a double layer of waterproofing on top of it.

Expanded clay it is not friendly enough to moisture, therefore, it requires serious waterproofing. For proper protection of the expanded clay layer from moisture, it is recommended to lay a double layer of waterproofing on top of it.

Insulation of the ceiling in a bath with a cold roof with mineral wool... Being a very popular insulation for steam rooms, mineral wool also has a number of clearly undeniable advantages. Fireproof, durable, with high thermal insulation properties - like no other material, it is better suited for ceiling insulation, for example, in a rest room, in a steam room or other bath room. That is why insulation of the ceiling in the bathhouse with mineral wool is the most commonly used move.

Warming with growing aerated concrete. The most modern and so far rarely used method of ceiling insulation, for example, in a steam room, dressing room, etc. It has a low thermal conductivity, is relatively inexpensive, absolutely environmentally safe, fire-resistant and durable, this material is also very quickly fit, thereby reducing the time for performing insulation work.

Each of the above methods, which is used to insulate a bath ceiling with your own hands from the inside, requires separate instructions for implementation. Within the framework of this publication, it is not possible to provide such instructions. Therefore, the choice of what is the best way to insulate the ceiling in the bath is up to the reader.

This, as well as other methods with detailed instructions a separate article or several of them will be devoted. It is then that we will try to fully disclose the topic and answer to the end the question of how to insulate the ceiling of a bath and what is the best way to insulate the ceiling of a bath.

» Insulation of the ceiling in the bath

The ceiling can quite reasonably be called the most important, in terms of insulation, construction. And anyone who is familiar with the laws of physics will understand why it is so. After all, warm air is lighter than cold air, which means that it rushes up, when cold - down. That is why the hottest air and steam are collected under the ceiling of the bath.

It is not hard to guess what will happen if it comes into contact with an uninsulated ceiling with good thermal conductivity. In addition, the larger the temperature difference, the faster the cooling. (You should not conclude from this that the floor does not need insulation - this requires it. Do not forget about the process of thermal insulation of which depends on the material:: or, especially in demand)

That is why we will consider here in detail the insulation of the bath ceiling from all sides.

Ceiling insulation in a bath: what?

| Minvata (basalt wool) | Processing product natural stone, does not burn, does not melt, but crumbles into dust. |

| Ecowool | Non-combustible cellulose, environmentally friendly, with low thermal conductivity, relatively cheap. |

| Foil | This is not a heater, but an infrared reflector, made of aluminum, often industrially combined with heaters. |

| Expanded clay | A clay fired product, lightweight and cheap, but it is worth checking the background radiation. It exhibits thermal insulation properties in a layer of 20-30 cm. |

| Expanded vermiculite | Withstands up to 1300 degrees! And thermal conductivity is better than foam. It does not cake during operation. 10 cm layer reduces heat loss by 92% |

| Clay + straw | The popular method of warming, very cheap, but requiring increased strength of the foundation and walls. |

| Sawdust + dry cement + hydrated lime + clay | Cement and slaked lime make sawdust less flammable and scare away rodents, clay or sand is added to make it heavier. |

How to insulate

The ceiling of the bath is usually insulated during the construction phase. Therefore, insulation is usually associated with the type of ceiling:

The ceiling of the bath is usually insulated during the construction phase. Therefore, insulation is usually associated with the type of ceiling:

- flat;

- hemmed;

- panel.

Mineral wool (\u003d basalt wool for baths, because it is the most environmentally friendly) can be used in any type, but flooring is considered the most budgetary, so cheaper materials are often chosen for it. Thermal insulation of the ceiling of a bath with mineral wool is a popular solution.

In any case, mineral wool needs insulation from water and steam, for which it is insulated on the one hand with a film or membrane, and on the other - with foil (as the best vapor barrier).

It should only be remembered that the vapor barrier is laid closer to the hot room (steam room, washing room), and the waterproofing is placed on top of the insulation already from the attic side. For a better understanding, we present the sequence of layers of two "pies".

The hem consists of:

- ceiling beams;

- cranial bars;

- boards;

- vapor barrier;

- insulation;

- clean ceiling (eg lining).

Video

The floor consists of:

- floor boards;

- vapor barrier;

- insulation;

- at the request of waterproofing (not at all necessary, except when dry sawdust is used, in which case a layer of clay or earth is needed on top for fire safety).

Video

See the explanation of the above picture:

Most often, in place of the insulation there is a mineral wool or glass wool (the latter should not be used only above the steam room).

Expanded clay -  a great way to insulate a cheap floor ceiling for a cold loft bath. You just need to make sure that the walls can withstand the weight of a 30-centimeter layer of this material.

a great way to insulate a cheap floor ceiling for a cold loft bath. You just need to make sure that the walls can withstand the weight of a 30-centimeter layer of this material.

The technology of insulation is simple for them: when boards are placed on the binding of the walls (about heaters for walls) (and there are no floor beams in the project), waxed paper is placed on top of them, and expanded clay of different fractions is scattered on top of it, leveled with a rake.

Then the foil is sewn to the boards from below with a stapler, the slats for the ventilation gap are attached to it, after which the final ceiling is attached. Insulation of the ceiling in a bath with expanded clay is a time-tested solution.

Styrofoam - the most undesirable material for the ceiling of the bath, because it does not withstand high temperatures, it is flammable, and during combustion it also emits smoke with toxic substances. However, harmful substances it begins to release even when heated. Nevertheless, many ignore the danger and put it to thermal insulation of the ceiling, because it does not make the structure too heavy and is among the inexpensive and available materials... Well, everyone is the smith of his own happiness. We advise at least not to put it over the steam room and next to the stove. And check the certificates: sanitary and firefighter.

Styrofoam sheets are placed on the outside of the bath ceiling on a pre-laid vapor barrier, for example, on a foil isolon. Or, instead of sheets, backfill with foam crumbs is used.

Thermal insulation of the ceiling of the steam room bath

The steam room is a special room in the bath, because it is here that any material is most tested due to the combination of high temperature and humidity.

The steam room is a special room in the bath, because it is here that any material is most tested due to the combination of high temperature and humidity.

One of the consequences of the influence of these factors can be the release of volatile compounds, for example, phenols or formaldehydes, contained in some species. Therefore, the thermal insulation of the steam room has to be approached with greater care than to other rooms.

In addition, everything near the chimney is literally hot, and the stove is the main source of sauna fires, so refractory materials will come in handy here.

- The rough ceiling is covered with waxed paper with a wide overlap at the joints.

- Bars of 5x5 cm are attached on top of the paper, between which insulation is then placed.

- Insulation is mounted.

- It is closed with a layer of vapor barrier - foil - with careful sealing of all joints and fastening holes with metal tape.

- On top of the foil, slats are stuffed, with the help of which the necessary ventilation gap is formed between the foil and fine finish ceiling.

- Decorative finishing - fine ceiling.

You should also familiarize yourself with the features, in particular, those used for external thermal insulation.

Correct insulation of the ceiling of a steam room Russian bath

The temperature in a Russian bath should not rise as high as in a Finnish one. After all, Russians go to the bathhouse for steam, while the Finns are satisfied with dry heat. The optimal upper temperature limit is 90 degrees. It follows from this that in the Russian steam room the materials are attacked not so much by the heat as by the steam.

That is why it is better to refuse to decorate the ceiling of the steam room with clapboard - it is suitable for a Finnish bath, and in a Russian it is better to take a massive aspen or lime board. The thickness of the tree first gains, then gently gives off heat.

A vent gap between the board and the vapor barrier is required, here it is also created by slats stuffed on foil.

Foil is also used in the Russian bath, there is no change here. It is better to put it here in two layers and with an overlap. In addition to foil, you can use foil Kraft paper or Penotherm, for other materials - see their temperature limits. The foil is admitted from the ceiling to the walls - 10-20 cm, and at the junction is glued with silicone sealant and closed with slats. But this is if the walls are without foil, and if with foil, then the ceiling is fastened with wall metal tape.

A rough ceiling with a thickness of 25 mm or more separates the foil from the insulation. The insulation is taken in three layers of 50 mm each (mineral wool) and placed with a shift in the joints so as not to create cold bridges. He does not need any backing, immediately on the boards.

On top of the insulation, if desired, a membrane is spread in the attic so that the insulation breathes and does not get wet from above.

Thermal insulation of the ceiling of the bath depends on the roof

It has already been said above that there are three ways to install a bath ceiling. In fact, there are two of them - panel is rarely used. And the rest are distributed between baths with a cold attic, where a simple and cheap floor ceiling is usually made, and baths with an attic, where hemming technology is used.

The difference between them, first of all, is that the floor is not intended for walking on it, so it is not even reinforced with beams, they just put the boards on the walls, cover them with paper and put a layer of thermal insulation, often the cheapest, but we have already talked about this.

Vapor barrier

Is it possible to do without a vapor barrier in a bath? Of course not, if you feel sorry for the tree. If you do not tend to spend money on wind and rot and your bathhouse, ceiling, vapor barrier is dear - this is what you cannot do without. Another thing is that there is a lot of controversy about whether to use foil as a vapor barrier. But this is already a matter of faith. In fact, those who cope with such work themselves can find their own answer - by steaming with foil and without foil. By the way, its advantages include high thermal stability, which means that if you put something else for vapor protection, then with a temperature range corresponding to a particular bath - Russian or Finnish.

We went through the popular YouTube channels, which tells about the baths with authority, knowledge of the matter, people whose opinion we ourselves listen to. But that's just bad luck - they tell a lot about something, but the problem of insulation of ceilings, and also does not attract everyone's attention for some reason.

Therefore, do not blame me, an example of expert advice on ceiling insulation will be the video below, made by “ Hot master"- nothing more significant was simply not found.

But what's interesting is that you won't hear standard descriptions in it. On the contrary, the authors of the video refer to the experience of previous generations and offer the most budgetary, simplest option for organizing both the ceiling itself and the insulation for it - this is a completely artless floor ceiling, insulated with ... sawdust and clay. It couldn't be easier.

You don't even need to bother with the clapboard - you can make the floorboards a clean ceiling, if you first shave and grind.

Of course, any opinion will be controversial, and you have the right to question it or not consider it expert.

Now, when it is already clear why a ceiling without insulation is warm to the wind, it remains only to wish each owner that in any weather his bathhouse would regularly warm up and keep warm for the second day.

Where to order or buy

Thermal insulation of the sauna ceiling is an important component of construction. Therefore, companies separately indicate performance in the list of services provided.

Some craftsmen prefer to carry out insulation work on their own. available for them.

In contact with

Any bathhouse needs high-quality insulation of the ceiling - warm air, according to the laws of physics, tends to rise up. And if there is no heat-insulating layer on its way, then much more fuel will be needed to warm up the bath and maintain a stable high temperature in it.

But this is not the only problem - in the absence of insulation, condensation will accumulate on the ceiling of the bath, and drops dripping on top of the head and back are unlikely to bring great pleasure to anyone. And the moisture that goes up along with the heat will contribute to the destruction ceiling slabs and roof support system. The only way to avoid these troubles is to make high-quality insulation of the ceiling in a bath with a cold roof. And our material will tell you what and how to make it from.

We plan work

Before buying materials and taking up tools, you should carefully plan your actions. A clearer understanding of the matter will save you from annoying mistakes and the need to redo everything in the future.

The first question is whether it is possible to insulate the ceiling in the bath on your own? Or is it worth entrusting this business to a team of builders? The process of insulating the ceiling itself is not something complicated, therefore it is not difficult to carry out it on your own, even without much experience in repair and construction. The main thing is to carefully observe the technology and approach the matter responsibly. The availability of the necessary materials also speaks in favor of self-insulation of the ceiling - they can be found in any large hardware store or on the market.

The second question is what, in fact, needs to be done? Ceiling insulation in a cold bath consists of three stages:

- vapor barrier;

- thermal insulation;

- waterproofing.

The result should be a kind of " layered cake», The lower layer of which is the ceiling covering, and above it there are sequentially vapor barrier, thermal insulation and waterproofing located from bottom to top. More details about why this is necessary and how to do it will be described below. Now is the time to think about the choice of materials.

We select insulation

A very high temperature and humidity is maintained in a melted bath. The thermal insulation material must comply with these conditions and, most importantly, not emit harmful substances when heated. In addition good insulation for a bath must be fire resistant. It is undesirable for the thermal insulation material to be too heavy or inconvenient to carry and install. Now let's take a closer look at the materials.

It is the most common type of insulation for baths and private houses; It is a fibrous thermal insulation material that exists in three types:

- glass wool;

- stone woolwhich is made from basalt or other rock melts;

- slag wool, made, like cinder blocks, from blast furnace slag.

The main advantage of mineral wool, in addition to its very low thermal conductivity, is considered to be that it is not a breeding ground for fungi, mold, insects or rodents. This is especially important for a sauna located on a private plot. It is also worth noting that this material does not burn, does not change its volume and shape when heated or cooled, and is very easy to install due to its low weight. Mineral wool is produced in the form of rectangular panels or in the form of rolls.

As for the disadvantages, there are two of them - the ability of mineral wool to absorb moisture (especially for slag wool) and the potential harm of the phenols they contain. Both of these drawbacks can be eliminated if you competently approach the issue of steam and waterproofing and prevent the contact of mineral wool with the air flow, especially inside the bath.

Important!Small particles of mineral wool can have a damaging effect on the eyes, skin or lungs of a person, therefore, when working with it, you must wear thick clothing and use gloves, goggles and a respirator.

Table. comparative characteristics various types of mineral wool.

Expanded clay

It is a small clay pebbles with a porous structure. By the combination of its advantages, expanded clay is the most suitable material for insulation of the ceiling in the bath.

- Security - it does not burn, is environmentally friendly and does not emit harmful substances into the air.

- Durability - expanded clay does not decompose under the action sun rays and does not deteriorate over time.

- This material not an attractive environment for fungi or bacteria.

- Has a low cost and is easy to install.

Also, expanded clay absorbs significantly less moisture than mineral wool, but the need for vapor barrier and waterproofing layers still remains.

Expanded clay

Styrofoam

At one time he was one of the leaders among thermal insulation materials. But even taking into account all its advantages, you should not choose polystyrene as a ceiling insulation in a bath - in a fire, the material burns well, and its smoke is very dangerous for human life and health. It is also capable of decomposing and simply under the influence of high temperatures (and in the bath they are inevitable), therefore, expanded polystyrene can hardly be called a reasonable choice in this case.

Styrofoam

Ecowool

Natural fibrous material made from cellulose with additives that impart flame resistance and protect against rodents, insects and microorganisms. Ecowool is lightweight and has the ability to fill all cracks and gaps. Like expanded clay, it is environmentally friendly and does not emit any substances harmful to humans into the air.

However, ecowool is capable of absorbing a lot of moisture, which impairs its thermal insulation properties. Therefore, when using it, good ventilation under the roof and high-quality waterproofing are desirable. Another disadvantage of its use is the complexity of installation - with the "wet" method of application, special equipment is required.

"Wet" method of applying ecowool

A mixture of cement and sawdust

It is a "classic" material for insulation, which was used even before mineral wool or foam appeared on the market. In some cases, clay can be used instead of cement, and straw can be used instead of sawdust.

First, a dry mixture is prepared in the following proportion: for 10 parts of sawdust, one part of cement and one part of lime are taken. The resulting dry mass should be poured with one and a half parts of water and get a sufficiently thick and homogeneous solution. The mixture is spread on the surface and distributed in a fairly even layer.

Important!It is advisable to use sawdust that has been dried for several months or better than a year.

Such material is very cheap and environmentally friendly, but at the same time it does not have such high thermal insulation as expanded clay or mineral wool. In addition, the process of its manufacture is laborious, and after laying it is required to close the resulting cracks (and they are inevitable).

Materials for steam and waterproofing

For a bath, a vapor barrier of the ceiling is vital, otherwise the rising moisture will not only worsen the thermal insulation properties of the insulation, but also contribute to the development of fungi and mold on the ceiling itself and on the roof rafters. Specialized films and coatings are used as a material for vapor barrier. Particular attention should be paid to anti-condensation membranes. When buying vapor barrier films, it is advisable to choose those that have a foil layer.

Important! When working with such films, be careful not to allow any breaks in the vapor barrier material or the foil layer, otherwise its protective properties will significantly deteriorate.

As for waterproofing, you can use both special films that can be found in any hardware store for it, as well as a cheaper roofing felt or dense polyethylene.

Common vapor barrier materials: 1. Geosynthetics. 2. PVC membrane. 3. Glassine. 4. Roofing paper. 5. Aluminum foil. 6. Thermofol.

Insulation of a floor ceiling

There are three main types of bath ceilings:

- hemming;

- panel;

- grazing.

Now we will consider the last type and find out how to insulate it and what nuances should be taken into account.

A flat ceiling is usually used for small baths, which are heated quite rarely and seasonally. Sheet pile or simple edged boards are laid on the upper part of the wall, adjusted to each other and fixed, without using support beams. The resulting structure is very simple, but at the same time it is unable to withstand a heavy load, therefore it is impossible to use a thick layer of thermal insulation here.

Important! It is advisable to lay the floor ceiling slightly below the height of the walls in order to leave space for backfilling expanded clay or laying mineral wool. If this is not possible, then the sides should be nailed along the perimeter of the ceiling under the roof.

The step-by-step insulation of the bath floor ceiling is as follows.

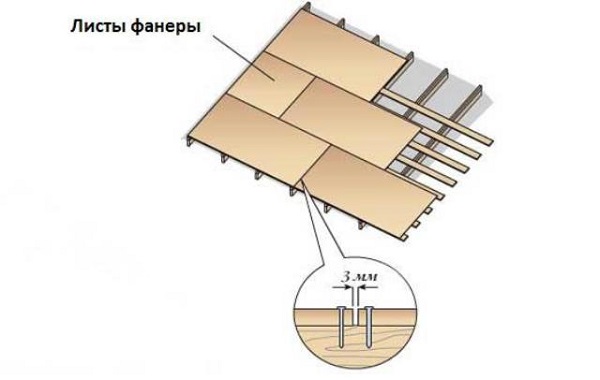

- From the side of the attic, a vapor barrier film is laid on the flooring so that the foil layer is directed downward. The material should be laid with an overlap of 10-15 centimeters, seams and joints are sealed with foil tape.

- Mineral wool is laid on top of the vapor barrier, expanded clay is poured or a mixture of cement and sawdust is laid, depending on your choice. Please note that it is undesirable to use a layer of insulation that is too thick, since a decking ceiling is not suitable for high loads.

- The layer of heat insulator is closed on top with roofing felt, plastic wrap or waterproofing coating, overlapping and with careful gluing of the joints.

- The final step will be to lay on top of the resulting "layer cake" sheets of plywood or boards.

It makes sense to use a flat ceiling in small baths and in the case when the simplicity and speed of its installation and insulation is important to you. If you plan to make a large enough steam room or arrange an attic under the roof for storing bath accessories, then your choice should be stopped on a false ceiling.

Warming of a false ceiling

Here, not the flooring itself is laid on the upper part of the wall, but support beams made of wooden beams or planks spliced \u200b\u200btogether. And already from below and above, the ceiling and floor of the attic are laid on the beams. At the same time, layers of steam, hydro and thermal insulation are laid in the space between them.

The very process of insulating a ceiling with a similar design depends on what material you use. For mineral wool, this happens as follows.

Video - We insulate the ceiling in a bath with a cold roof using mineral wool

The process of insulating the hemmed ceiling of a bath with a cold roof looks a little different when expanded clay or a cement-sawdust mixture is used. Let's imagine this in the form of step-by-step instructions.

- From below, a rough flooring of boards is laid on the floor beams. The gaps between them must be treated with a sealant or smeared with a mixture of clay (or concrete) and sawdust.

- A vapor barrier film is laid on the flooring both from the steam room and from the roof, and not only the boardwalk should be covered, but also the beams themselves.

- Expanded clay is poured into the resulting boxes or ecowool is laid.

- Roofing material or other waterproofing material is overlapped on top of the insulation and attached to the beams using a construction stapler.

- Boards or plywood are laid on the waterproofing to form the attic floor.

- Lining is laid on the bottom of the rough boards.

If you use a mixture of clay and sawdust to insulate the ceiling, it is advisable to put a layer of mineral wool on top of the hardened mixture or fill in expanded clay - this will improve the performance of thermal insulation.

Important! The optimum layer thickness of a mixture of clay and sawdust for using the bath in the warm season is 50 mm. If you plan to bathe in it in winter, then you will need to make a layer of insulation of at least 150 mm.

Insulation of a panel ceiling

Such a ceiling design is the most difficult for self-made - first you need to make the panels themselves, and then lift them up and fix either on the cross beams or directly on the top of the walls.

Each of the panels is manufactured as follows.

- On the support bars, a layer of boards, carefully adjusted to each other, is laid perpendicularly. This layer will serve as a ceiling for the bath.

- Boards are attached to the inner side of the resulting shield, which will serve as the sides of the panel.

- A vapor barrier material is laid on the boards and sides and fixed with a construction stapler.

- Mineral wool or ecowool is placed in the inner space of each panel. You can also use a cement-sawdust mixture or expanded clay, but in this case the panel will turn out to be especially heavy.

- On top of the heat-insulating material, a polyethylene film or roofing felt is laid, with overlapping joints by 5-10 cm.

- The top layer of boards is laid, which will serve as the floor for the attic.

The resulting panels should be lifted and mounted, while it will not be superfluous to put solid boards on them from above and below, connecting all the panels to each other. The joints between them also need to be insulated with strips of mineral wool scraps. Alternatively, you can take the same mixture of cement and sawdust.

Advice! The assembly of ceiling panels, their lifting and installation is very laborious. Therefore, it is advisable to use any lifting device and work not alone or in pairs, but as a whole team.

Choose the type of ceiling and used insulation material follows, based on the budget, own experience construction works, bath area and how often it will be used.

Video - Ceiling arrangement in the bath