Warming the air layer of the house with penoizol. Penoizol: reviews. Who insulated - opinions, characteristics, advantages and disadvantages. Traditionally, penoizol in construction is used for

In the previous article, we wrote about ... Today we will tell you about insulation with penoizol. Reviews of people knowledgeable in this matter indicate the importance of following the rules for working with this material. It is important to observe the proportions when mixing, otherwise the material will not have its declared characteristics and may even be poisonous. Being a descendant of polystyrene, this material has absorbed all its positive qualities, and in some aspects surpassed it. At the same time, the scope of application of penoizol is somewhat narrower, due to its fragile structure.

What is penoizol made of, types

One method is spraying the walls.

Today appeared new trend - this is insulation with penoizol. Reviews of contractors agree that the result primarily depends on the quality of the materials used for the manufacture. Penoizol is polymer material, which in its qualities is close to polystyrene. Its production, as a finished raw material, has not been established. Plants only produce components. For the production of penoizol used:

- resin - urea-formaldehyde, marked with letters KFMT;

- orthophosphoric food acid;

- foaming agent - alkylbenzenesulfonic acid, marked with the letters ABSK;

- water with medium hardness.

Insulation of walls with penoizol made of low-quality materials or with non-compliance with technology will not give the desired result. So, for example, KFMT profile resin can be replaced with a cheaper analogue used for chipboard production... Non-observance of proportions and temperature regime... Wall insulation with penoizol should be carried out at +20 and above. The proportions of the components:

- resin - 20 kg;

- orthopressor acid - 400 g;

- alkylbenzenesulfonic acid - 100 g;

- medium hard water - 25 liters.

As a result, we get liquid material, which is poured into cavities between walls and floors. But this is far from the only method of wall insulation with penoizol. Reviews still agree that it is the most popular and effective, but it also eats other options. Penoizol can be:

- liquid;

- in sheets;

- in granules (crumb).

Liquid penoizol is the basis for the production of sheet material.

In order to get sheets of penoizol, you need to pour liquid material into a mold, a regular cube. When the insulation hardens (polymerizes), it can be cut into sheets of the required thickness. This is done both by hand with a string and on special machines.

The crumb is made from carbamide foam. It is important that the fractions are not small - at least 10–15 mm, and also sufficiently elastic. To make a crumb, they take one cubic meter of foam and crumble it, as a result of which small balls (grains) are obtained, the volume of which is twice the original. That is, if we crumble 1 cubic meter of foam, we get 2 thousand liters of crumbs. There are some features during work, but wall insulation with penoizol, according to reviews, is more profitable when using crumbs.

Penoizol characteristics

Another method is pouring liquid material into the space between walls.

How effective is house insulation with penoizol? Reviews of those who have already tried the new product say that there is a benefit. It is associated with some characteristics of the material, which allow you not to use additional insulation. In principle, penoizol slightly outperforms its relative - polystyrene. Main characteristics:

- thermal conductivity - 0.028–0.038, despite the fact that for foam plastic these indicators reach 0.048;

- density - from 10 to 30 kg / m. cube;

- does not burn at all;

- service life of more than 50 years, which is twice as long as that of ordinary foam;

- better moisture permeability, that is, breathes.

All these characteristics favorably distinguish penoizol, but only if they insulate the spaces between the walls, the ceiling or the floor. For example, it is inapplicable for facades for plastering - it crumbles too easily, does not withstand even a minimum mechanical load.

In some sources, you can find statements that mice do not gnaw, although this is not the case. Even in minwat, sometimes mouse clans thrive, not to mention their beloved polystyrene foam and its derivatives. The ability of penoizol to pass moisture has a positive effect on the indoor microclimate. Thanks to this, condensation does not form and, accordingly, the associated problems: fungus, musty odor, the need for good ventilation or constant ventilation.

How to insulate a house with penoizol

This is a crumb of penoizol, transported in bags. Blown out with a compressor.

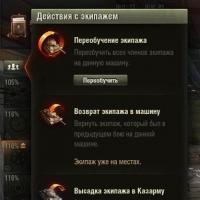

It is necessary to consider insulation with penoizol with your own hands in three planes, since the material can be in three states, as described above. Let's start with the most common and convenient way Is the filling of voids with liquid material.

To insulate a house with penoizol you will need:

- installation for mixing the components of the composition;

- large volume containers;

- compressor.

As you understand, the process of thermal insulation begins with mixing the components of penoizol, since everything must be done locally. After the composition is ready for work with the help of a compressor, it is blown into the prepared cavity. If we are talking about roof insulation with penoizol, then the buffer zone between the roof rafters acts as this cavity itself. To prevent the material from leaking out, a dense plastic film is stuffed onto the rafters from the inside. The degree of filling the voids is visible visually, since the film is transparent. If the distance between the rafters is too large, then to hold the layer of insulation, you can stretch a nylon thread or wire in zigzags between them.

Penoizol sheets are similar to polystyrene, only the grain fraction is much smaller.

To insulate the ceiling with penoizol, simply spray it over the ceiling in the attic. As a result, a monolithic layer of insulation is obtained, which does not allow heat to pass through, while moisture does not stagnate under the ceiling. As you know, ceiling insulation is technologically more complicated than walls. We wrote about this in the article: “ ».

The ceiling must breathe, therefore, membranes are used that allow moisture to pass through, but do not allow heat to pass through. Such membranes are not needed for penoizol. Insulation of floors with penoizol is performed according to the same principle as for the ceiling. Sprayed under the sub-floor required amount liquid material. After hardening, it is quite fragile, therefore, the possibility of its damage during operation cannot be allowed. The same cannot be said about extruded foam, which is quite tough and can even fit under the screed. We talked about this in the article: “ ».

The use of boards made of penoizol is justified only due to their low weight and absolute fire safety.

Although there are difficulties with this material. For example, due to the fact that it is too fragile, it is difficult to transport it so that it does not lose its shape. Even a gust of wind can break the sheet, so they are made at least 10 cm thick.

Penoizol crumb at correct use is slightly cheaper than a liquid analogue. But there are even more problems with her:

- accurate calibration of equipment is required;

- you need to work only with absolutely dry material;

- with incorrect calibration or a small grain fraction, the filling density increases, the material consumption also increases;

- there is a lot of garbage when working.

Those who are exclusively engaged in warming with crumb do not recommend doing the work on their own.

The process has many nuances, failure to comply with which will undoubtedly lead to negative consequences, such as the formation of voids or overspending of material and funds.

Penoizol liquid insulation - where to look for a catch

Whether it is insulation of the ceiling with penoizol or walls, almost everything depends on the level of skill of the performer. Naturally, you need to look at the resin certificates, but does this mean that the certificate was issued for the resin that is used to insulate your house? Probably the main indicator of the good faith of the contractor's firm is the willingness to enter into a contract with long-term quality guarantees. A negative result may appear in 2-3 years.

The main problems arise not from installation or equipment, but from improper mixing of components:

- busting with resin - too loose material;

- overdose of phosphoric acid - penoizol burns out and simply crumbles in the hands.

Also, if the proportions are not observed, formaldehyde is released - a terrible poison. Based on the results of all that has been said, we can conclude that it is possible to use Penoizol liquid insulation if intelligent specialists work with it. Crumb and slabs are not very popular, and most likely, they will not be widely used. Although the material contains toxic substances at the correct dosage, they do not carry any harm.

Market building materials is constantly being improved. New technologies are emerging that improve the quality of existing products. At the same time, repair and construction work is carried out faster and cheaper. Penoizol is one of the new materials that is gaining popularity today. It has a lot of positive characteristics.

general characteristics

The name of the presented insulation is the name of the trade mark. There are many other companies that manufacture the same product but under different names. All of them are urea foam.

Among the domestic analogues of penoizol, one can name unipor, ecoizol, mettemplast, mipora, teploizol, etc. Foreign names of the presented material are also diverse. In Great Britain, urea foam is called flotofaum, in the Czech Republic - mofotherm, in Switzerland - isoshaum, etc. The principle of the presented compositions is the same.

The cost

One of the main advantages of the presented insulation is its price. Penoizol costs about 600 rubles / m³. At the same time, the quality of thermal insulation is not inferior to the popular heaters existing on the market today.

If we compare penoizol with mineral wool, a product with similar thermal conductivity will cost the consumer 1.5 times more. At the same time, the price of this insulation is 900-1000 rubles / m³.

The price of penoizol is 1.5 times lower than the cost of foam. A material with a similar thermal conductivity costs 950-1000 rubles / m³. The cost of extruded polystyrene foam is 6.6 times higher than that of expanded polystyrene. It is about 4 thousand rubles / m³ (taking into account the thermal conductivity coefficient).

Also, in terms of cost, urea foam is more profitable than basalt slabs, staple fiber and expanded clay. For this reason, many private property owners prefer this type of material.

Structure

It has a lot of advantages. The material is similar in structure to marshmallows. Manufacturing is not expensive. Therefore, the cost of the product is relatively low. After processing, a semi-liquid foam is obtained at the exit.

After drying, this material is highly elastic. Dents from various blows on it quickly straighten. The material has high thermal insulation characteristics, repels moisture.

When creating penoizol, a certain type of carbamide resin is used. Acid is added to it. Foaming additive in a certain proportion is used in the composition of the product. A mixture of the listed components is put into the equipment. Compressed air is supplied to it. At the exit, the substance has a jelly-like consistency. It can be applied directly to the base of the wall.

Installers reviews

Penoizol characteristicsdetermine its method of application. After the mass leaves the sleeve of the unit, it solidifies. However, this process takes place gradually. The material sets to the substrate 10 minutes after application. In this state, penoizol remains soft.

After another 4 hours, the mass solidifies. She's getting hard enough. However, penoizol has not yet gained strength. It will take several more days for the insulation to be ready for subsequent finishing. It gains strength over 3 days. During this time, Penoizol acquires all its positive qualities.

Professional installers claim that thermal insulation of the presented category is mounted much faster than other heaters. The surface treatment speed will be 4-5 times higher. At the same time, the material is characterized by low weight. It makes the structure slightly heavier.

Thermal conductivity

After hardening, it has a lot of positive qualities. Low thermal conductivity is one of its main advantages. The material can significantly reduce the cost of paying for energy resources in winter period.

Depending on the features of the structure, as well as the method of installation of penoizol, its layer can be from 5 cm to 1 m.When a layer of 10 cm thick is applied to the surface, it becomes much warmer in the room in winter. Penoizol thickness is selected individually for each object. At the same time, the climatic features of the area, the features of the building itself, are taken into account.

Depending on the density and composition of the material, the thermal conductivity coefficient can be 0.031-0.041. This is a good indicator. Apply the presented material for both external and internal insulation... When creating a layer of insulation from penoizol indoors, you can not be afraid of condensation on the walls. In this case, the finish will last a long time.

Fire resistance

after application on various surfaces within 3 days, it gains its basic qualities. In addition to low thermal conductivity, after curing, penoizol demonstrates high fire resistance. In this it compares favorably with many heaters.

Even with very high temperatures the presented material does not ignite or even melt. However, it does not emit smoke and substances hazardous to human health. It is an environmentally friendly material. Due to its resistance to fire, penoizol can be used in a wide variety of private and industrial facilities. It is operated in the thermal range from -60 to +80 ºС.

To understand how penoizol behaves at elevated temperatures, the following situation should be considered. If the ambient temperature rises so much that the metal begins to melt, the provided insulation will simply evaporate gradually. This prevents hazardous chemicals from being released into the air. Smoke in a fire from penoizol is 10 times less than from expanded polystyrene.

Resistance to various influences

Which forms an insulating layer on various surfaces inside and outside the premises, it is highly resistant to various biological and chemical influences. The material is not subject to the destructive influence of various solvents and active substances.

In the presented insulation, various insects do not start, it is not gnawed by mice. The fungus is also unable to multiply on its surface. These qualities make it possible to create a healthy indoor climate.

One of the advantages of the material is its air permeability. This allows you to regulate the humidity level in the room. The owners of such a house note that the microclimate in the room is healthy, there is no dampness. It is dry and warm inside the building. Various pathogens practically do not reproduce in such an environment.

Moisture absorption

Many installers today use penoizol in cylinders... This insulation is very easy to use. At the same time, thermal insulation is characterized by a high level of moisture absorption. It also releases it well into the environment. This allows you to maintain an optimal level of humidity.

If penoizol gets wet, it dries quickly. At the same time, its initial characteristics remain unchanged. This process does not affect the properties of the insulation in any way. It retains heat well in the room, does not ignite. The walls will not be damp. However, experienced installers recommend not neglecting good ventilation.

The hygroscopicity of the presented insulation allows the walls and finishing materials to deteriorate much more slowly. At the same time, a layer of insulation can absorb from 10 to 20% of moisture from the environment per day.

Strength and durability

It is characterized by high softness. Once on the base, it adheres well to any surface. At the same time, the insulation layer qualitatively covers all irregularities. No voids or gaps appear under the thermal insulation.

Penoizol gradually gains the strength set by the manufacturer. However, it is not very tough. When bent, the material breaks. When you press the material, it expands quickly. The elasticity of such insulation remains high. But when bent, the insulation does not show high strength.

When conducting research on the characteristics of penoizol, it was found that it is capable of operating at correct installation 30-50 years old. These data are confirmed by laboratory tests. In construction, the presented material has been used relatively recently. However, according to its main operational characteristics, it becomes clear that this is a durable insulation.

Negative reviews

In various sources, you can find many positive and negative reviews about penoizole. Who insulated with this material their home, in most cases, they are satisfied with the result. However, there are also negative reviews.

After pouring penoizol, its shrinkage is from 0.1 to 5%. This is an insignificant figure. However, with insufficient vocational training master or when using low-quality material, this figure may increase.

There are also reviews about the unpleasant smell of insulation that appears during the drying process. This phenomenon occurs only with low quality products. You should not contact dubious installation organizations. When penoizol dries, a small amount of formaldehyde may be released. However, its amount is insignificant. It is enough to leave the windows in the room open in order to get rid of the insulation when the insulation hardens. unpleasant odor fast.

Positive reviews

Minor disadvantages of penoizol cannot influence its relevance and ever-growing popularity. There are many positive reviews from those who installed the presented material at home, speaking of the high quality of the insulation.

When applied, the room becomes much warmer. Energy bills decrease during winter. At the same time, it becomes warm in the room, the level of humidity is kept at an optimal level for human health.

Installation is very fast. Moreover, the cost of such finishing will be several times less than when using other types of insulation.

To perform quality insulation with penoizol, it is necessary to contact only approved installers. They provide a guarantee for their work. Materials used for insulation must have appropriate quality certificates.

The finished penoizol should not settle. He has white color... After drying, the material has a cellular structure. There should be no air bubbles in it.

To draw conclusions about the advisability of using a heater from urea foam will help reviews penoizole. Who insulatedtheir home with the presented material in most cases are satisfied with the result.

Building a house is an important process in which you need to take into account many nuances. Every year, more and more requirements are imposed on the construction of housing, especially in terms of achieving energy and fuel savings. Modern materials can significantly help in this, however, they should be chosen correctly. For example, recently such material as penoizol has received positive reviews and competes with more popular ecowool and expanded polystyrene. What are its features? And why do you need to insulate your house at all?

How to insulate a house?

Let's start by answering the last question. In any house or apartment, especially in those that were built back in soviet times, heat losses are too great - they can reach 40%. In the end, you have to spend a lot of money on heating your home, because heat leaves our homes through the outer walls, floors, windows, doors, and also the roof. Modern methods of insulation, for example, insulation with penoizol, allow solving a number of important issues:

- The optimum room temperature will be maintained throughout the year.

- The walls will be protected from moisture, condensation accumulation, which means they will be reliably protected from mold and mildew.

- The acoustic properties of the building will improve.

- The level of noise insulation in the room will be higher.

- The hygienic condition of the room will be much better.

- Lower energy costs.

- The erected house will be more durable and economical to operate.

Of course, even insulating houses with penoizol will not completely protect the premises from heat losses, but at least they will be minimized. In addition, it is important that the installation of the insulation material is carried out competently and professionally in compliance with the technology.

Penoizol: what are the features?

As a rule, ecowool and polystyrene are most often used as insulation, but today penoizol is also becoming quite popular. It has many advantages, each of which plays a role in forming such a good opinion of the material. Firstly, penoizol is completely uninteresting to rodents and microorganisms, so you don't have to worry that the walls will gradually be eaten from the inside. It is noteworthy that if this material is subjected to mechanical action, it will turn into dust. The second important point is that penoizol receives positive reviews due to its breathable structure and good thermal insulation properties. Due to the presence of capillary moisture transfer in the material, it can be safely used in wooden construction, thus excluding the appearance of mold. All excess moisture will be eliminated by the capillaries of the insulation. The third positive point is that compared to ecowool and glass wool, the material we describe is hermetic, it literally fills all the pores and details in its path.

The porous structure is the key to reliability

The studies carried out allowed us to bring together all the features that Penoizol has. Its characteristics are as follows:

- The resistance coefficient is 40% higher in comparison with mineral wool and cellulose insulation, which means that the level of heat loss will be minimal.

- Penoizol is not afraid of moisture, which can destroy wood and lead to defects in the walls or roof. The material has a porous structure, so all the accumulated moisture dries instantly, which means there is no reason for worry.

- Average insulation sags for 10-12 years, respectively, there may be cracks in the walls or floor. If insulation with penoizol is chosen, then this can be avoided, because it fills all the pores, and its service life can reach 70-80 years.

Where is Penoizol used?

The modern homeowner is always faced with the choice of quality and reliable materials, especially when it comes to thermal insulation. Penoizol received positive reviews precisely due to the fact that it is a unique combination of price and quality. In addition, this material can be used to insulate both the floor and the roof both in new buildings and in existing buildings. Penoizol is a carbamide foam with a cellular structure. Due to its excellent physical and chemical characteristics, the scope of the material is quite wide. The material is released in the form of liquid foam, so it can easily fill all cavities in which it quickly solidifies. For wall insulation, you can also choose sheet foam.

Features of the insulation of a wooden house

Wooden house building is popular due to the fact that the walls in such buildings "breathe". But this same characteristic makes the process of warming rather difficult. For example, it is almost impossible to insulate the facade of a log house, but penoizol received good reviews in the timber version. It is possible that this material can also be used for a panel house, however, in such cases, it is not liquid foam insulation that is used, but sheet one, which is pre-mounted on a prepared profile.

Wall insulation: what to consider?

Penoizol insulation for walls is the most optimal solutionsince he:

- does not burn;

- resistant to mold, mildew, rodents;

- vapor permeable, that is, excess moisture comes out;

- durable (service life is at least 50-70 years).

Due to its excellent thermal insulation properties, it is not only convenient, but also profitable to insulate a house with penoizol, since it is easy to install and keeps heat well. Penoizol can be laid in two ways - in the form of plates or thick foam. In this case, it is important that the resistance to vapor permeation of the inner layer is higher than the resistance of the outer walls.

Secondly, you should not choose a film, foil, roofing material as a vapor barrier material, since there will be no air gap between the walls of the building and the outside area. To increase the efficiency of using this insulation, it is best to combine it with wood, concrete, brick or plaster. When laying the slabs, avoid the gap between the slabs and the wall.

Stages of wall installation

The process of wall insulation will consist of several stages:

- Installation of sheet insulation in the masonry during the construction of walls.

- Sheathing of external walls with sheet material, after which they are lined.

- Laying sheet insulation on interior walls under the finishing material.

- Filling crumbs of penoizol into the voids of the walls, as well as under the drywall.

Attention to the ceiling and facade

Penoizol is also well suited for ceiling insulation. True, experts recommend using it in rooms with a large area, since the presence and work of professional craftsmen will be required. easier. Due to the fact that penoizol has excellent characteristics, it is able to become reliable protection walls. The essence of facade insulation is as follows. First mounted on the wall basic structure, for example, from a galvanized profile. Magnesite plates are screwed onto it, in which holes are made - it is here that penoizol is poured. After its polymerization and hardening, the walls can be painted or revetted decorative materials... For the facade, this solution is quite convenient and functional, since penoizol in combination with magnesite plates has good vapor permeability. The walls will "breathe", maintaining a favorable indoor climate. In addition, the facade will meet all fire safety and soundproofing requirements.

Floor and roof

Penoizol is excellent for floor and roof insulation, but it is important not to forget about the ventilation system. The installation process itself includes several stages:

- Installation of material under the flooring (under concrete screed or between lags).

- Laying sheet insulation in the attic, attic, as well as technical floors.

- Installation of penoizol in the suspended ceiling.

- Roofing system insulation.

- Filling crumbs of penoizol in the floor, attic.

Depending on the design features of a specific residential building, along with sheet material, penoizol pouring can also be used. This type of foam can be poured directly on the construction site. The effectiveness of this method is that the liquid material does not expand in volume and "shrinks" slightly. Accordingly, in order to avoid the appearance of cracks in the walls, it is important to strictly follow the technology of its installation. Liquid penoizol should be used at an air temperature of at least +1 degrees. With such a composition, it is quite possible to insulate already operating buildings, filling voids and cavities in structures, which at the same time will remain strong.

How is it produced?

In modern construction, such insulating material as penoizol is quite in demand. Its production is carried out on the basis of a specially prepared foaming composition with the addition of various components. Due to them, the physical and mechanical properties of the material change, and also its operational characteristics are improved. A foam mass appears from a special foam-forming sleeve, from which then a heater will turn out. It hardens within 15 minutes - this is the first stage. The next stage occurs in about 3-4 hours.

Penoisiol contains approximately 90% of the gas sphere, but the following components are supposed to be used as raw materials:

- orthophosphoric acid;

- foaming agent;

- resin;

- carbamet;

- water.

Equipment features

Equipment for the production of penoizol is a number of units that are inexpensive. First, it includes a gas-liquid plant that directly produces foam insulation. It consists of GZhU, a supply hose, a set of valves for connecting tanks, as well as various application documents. Due to its compactness, the unit can be easily transported. Secondly, you need a compressor that produces compressed air. Thirdly, for the production of penoizol, containers will be required - ideally, there should be three of them. In this capacity, you can use ordinary barrels made of polyethylene or iron with a volume of 30-200 liters. For the convenience of transporting the unit around the construction site, it is advisable to purchase a trolley with GZhU. Thus, to create such a material as penoizol, the installation must be completely assembled.

How and where is Penoizol used?

Urea foam is used quite widely, while in different countries it is produced under various brands and names. It is due to the manufacturability of the material and its excellent performance characteristics that penoizol is so popular as In most developed countries, it is the filling of the souffle-like penoizol in the cavity that is used. However, this material can be used in non-standard ways. For example, in the Czech Republic, reinforced concrete panels are used in three layers, one of which is just 50 mm thick foam insulation. In the USA, concrete blocks are used for construction in which cavities are filled with penoizol.

In Poland and Hungary, the use of this material is due to its resistance to combustion, therefore, in these countries, landfills are poured with it - a kind of coating protects waste from ignition.

Porous foam is used as a thermal insulation material in the Netherlands, Poland, France, and also in the Baltic States. When building houses, a gap of 40-60 mm is traditionally left between the walls, which is subsequently filled with a foam-insulating mass.

Why is penoizol so popular?

In search of quality insulation materials many builders are looking for something that is not only reliable, but also economical in terms of cost. As a rule, the use of penoizol is explained by the fact that it is good for them to insulate buildings with a wall thickness of about 10-20 mm, since this will reduce the cost of heating the house several times. And the cost of the work carried out on the insulation will pay off already during the first operation of the residential facility. Using urea foam to decorate interior wall openings or insulate the facade of a house, you can effectively protect it even in severe frosts. An important role is played by the cellular structure, which perfectly protects indoor spaces from noise penetration.

What is penoizol, how is it produced, types of insulation, specifications, advantages and disadvantages, rules for choosing material and equipment for its application, short instruction DIY installation.

Description and features of the production of penoizol

In fact, penoizol is a modified foam that is not afraid of fire and does not emit any harmful compounds. In addition, it has good thermal insulation properties. In appearance, it resembles a marshmallow, and its installation is carried out by spraying onto the surface using special equipment.

The raw material is urea resin, phosphoric acid, and a foaming agent. All components are mixed in a precise proportion and put into the device. Under the influence of compressed air, a white jelly-like mixture is pumped out. It fills in all gaps and gaps and turns into a lush foam when solidified.

The hardening process takes place in several stages. After 10-15 minutes, the composition sets. After 3-4 hours, the foam hardens slightly, but is still not strong enough. It gets its final strength after 2-3 days.

The finished substance is polystyrene, but not solid, but semi-liquid. It is elastic, and any dents from mechanical stress on it are quickly straightened. The air content in it reaches 90%. Outwardly similar to expanded polystyrene, but has smaller cells and has better technical characteristics.

For its features, the material has become widespread in the field of insulation of already erected private houses. They can insulate walls, ceilings, roofs, floors, interfloor ceilings, structures of complex shapes.

The main types of penoizol

Thermal insulation of buildings can be carried out different kinds urea foam. There are three of them:

- ... The most common type. Its ease of use lies in the fact that the composition is being prepared directly at the construction site. It is used for thermal insulation of erected structures, as well as for repair purposes. Foam can also be poured into confined spaces to create a middle layer of heat and sound insulation in combination walls, sandwich panels, frame buildings... When conducting renovation works cavities, gaps, cracks are filled with liquid penoizol.

- Granular penoizol... It is also called thermovat or foam-insulated crumb. The manufacturing process consists in crushing the polymerized material into fractions of 10-15 millimeters in size. Such granules remain elastic. Such penoizol is advantageous in that when the polymerized insulation is crushed, the volume of the crumb doubles. Thus, you can save on the installation of thermal insulation. This material is used for laying on the floor, interfloor ceilings, in inter-wall cavities, on the foundation.

- Sheet penoizol... It is made by pouring a liquid semi-finished product into a special mold. After the mixture hardens, it is cut by hand or on machines into sheets of the required thickness. Then the material is dried, the process of finishing mechanical processing... They can also isolate structures under construction. It is installed with dowels outside the building. The top is sheathed with a decorative coating, for example, siding. In addition, penoizol plates are placed on the floor between the logs.

Penoizol technical characteristics

By its properties, penoizol surpasses traditional insulation in many respects. Let's consider the main characteristics:

- Thermal conductivity of penoizol... This indicator is quite low for this insulation. The coefficient ranges from 0.031-0.041 watts per meter per Kelvin. To achieve good thermal insulation results, it is sufficient to lay a layer of 10 centimeters. Thus, the cost of the material will be recouped due to the savings on heating costs already within one winter.

- Soundproofing... This insulation has decent sound absorption performance. In percentage terms, this is about 65%.

- Fire resistance... Penoizol is classified in the G-1 flammability group, that is, a material that does not burn well. The flammability group of this insulation is B-2. This means that it does not melt when exposed to fire. It was also assigned to the D-1 group for its ability to emit smoke and T-1 for toxicity. The use of a heat insulator is permissible within the temperature range from -60 to +80 degrees Celsius. At high temperatures, the material will simply evaporate without emitting toxic compounds. In an open fire of smoke, penoizol will emit ten times less than foam.

- Chemical resistance... The insulation does not react to a chemically aggressive environment, various organic solvents.

- Moisture resistance... Penoizol absorbs moisture well, but it gives it away just as easily without deteriorating its qualities. The material absorbs 1/5 of the moisture, evaporating it later. To avoid the appearance of mold on the walls, it is recommended to make a ventilation gap. During the day, the heat insulator absorbs 10-20% moisture.

- Vapor permeability... Since this insulation is hygroscopic, the walls are able to "breathe". Air freely passes through structures that are insulated with penoizol.

- Biological resistance... Penoizol insulation is not afraid of fungus, mold, microorganisms. Domestic rodents do not gnaw holes and passages in it, do not use it for food.

- Strength... The material has a special softness, so it adheres well to all surface irregularities, completely filling the gaps and crevices. Compression strength at linear deformation of 10% is 0.07-0.5 kilograms per square centimeter. When bent, this figure is 0.1-0.25, and when stretched - 0.05-0.08 kilograms per square centimeter.

- Lifetime... Penoizol production began not so long ago - only about 50 years ago. Therefore, it is possible to establish indicators of its durability only approximately. On average, manufacturers talk about 30-50 years of material exploitation.

- Sustainability... High-quality penoizol does not emit any volatile toxic compounds either during installation or during operation. Even exposure to fire does not generate harmful smoke.

Penoizol advantages

This insulation has many positive features that distinguish it from other types of polymer heat insulators. Consider them:

- Excellent thermal insulation ability... The 45mm foam insulation layer provides the same level of cold protection as 75mm foam and 125mm mineral wool.

- Resistance to many types of mechanical stress... When pressed, the elastic material will creep in and quickly return to its original shape after the pressure is released.

- Resistant to temperature fluctuations and increased humidity... Temperature drops do not have any effect on penoizol, and the material absorbs water and quickly evaporates into the atmosphere.

- Good vapor permeability... Thanks to this quality, the walls and roof will not deteriorate under the influence of condensation. Therefore, penoizol is recommended for insulation and insulation of wooden buildings.

- High adhesion... The heat insulator perfectly "sticks" to any surfaces, penetrating into the smallest cracks and holes. It is convenient for them to insulate structures of complex or carved shapes.

- Low cost... The material itself is relatively inexpensive. The price of penoizol is comparable to the prices for mineral wool from well-known brands. At the same time, you can save money by performing assembly work with his own hand.

- Fire safety... When exposed to fire, the material does not burn, but only "melts", releasing water, nitrogen, carbon dioxide into the air.

- Versatility... Penoizol can be selected in any form of release for any need. They insulate almost all possible structures, preferably of a closed type.

- Lack of "cold bridges"... This quality is applicable to liquid and granular material.

Disadvantages of penoizol

Like any other heat insulator, penoizol also has a number of disadvantages. The main ones include the following:

- Material shrinks... It is 0.1-5%. Only penoizol does not have this property, which is poured between the walls and is under pressure.

- Low tensile strength... The low density of the insulation explains the fact that it can be torn quite easily.

- High moisture absorption... In some situations, this quality can be considered a disadvantage. So, because of this, you should not use Penoizol for installation under a screed, in the underground part of the foundation. It is also recommended to apply an additional layer of waterproofing.

- The need for special equipment for applying liquid penoizol... It can be bought or rented. You can also hire a professional team.

- Installation is possible only at temperatures above +5 degrees... High-quality foam can be obtained only if the temperature regime of operation is observed.

Criteria for selection of penoizol and equipment for installation

As a rule, liquid penoizol is chosen for household insulation, which is applied using special equipment. It can be bought or rented. The latter option is preferable, as it will cost significantly less.

- There are two types of installations for the installation of penoizol. These are gas-liquid and pneumohydraulic devices. For example, to carry out work on the insulation of your own house, you can choose budget equipment GZHU "Mini".

- Do not take a unit with a built-in compressor without a receiver.

- The plunger pump of the installation must be made of plastic or stainless steel.

- Do not choose equipment for penoizol with a plunger pump, where there is no speed control function.

- Refuse to purchase equipment in which the foam generator is attached directly to the pumping unit.

- Before buying penoizol, ask the seller to mix the solution in the right proportions and make a little foam. The sample should be pure white. The resin should be of the same color.

- Foam should not shrink or shrink noticeably immediately after application.

- After 15 minutes after spraying, you can pat the material with your hand. Moreover, it should not break through.

- There should be no large air gaps in the frozen foam. The cells are ideally small and uniform.

- High-quality solidified penoizol breaks down with little effort. Only slight shedding may occur at the edges.

- With slight compression, the material should quickly regain its original shape.

Price and manufacturers of penoizol

Since penoizol is a trade name for urea foam, it is worth noting that in Russia the rights to use this mark belong to the NST (New Construction Technologies) company.

IN different countries you can find various names of this material: Mofotherm (Czech Republic), Flotofoam (Great Britain), Animotherm (Germany), Isolezh (France), Insulsprey (Canada), Yporka (Japan).

In Russia, such large enterprises are engaged in the production of urea resins, which are the basis for penoizol: OOO Tomskneftekhim, ZAO Metadynea, OAO Togliattiazot, OAO Akron, OAO Karbolit. The most common brand of this substance, which is used by manufacturers, is KF-MT. The price for it starts at 44 rubles per kilogram.

In addition, phosphoric acid is needed to form the foam. Its price on the Russian market is from 170 rubles per kilogram. The ABSK foam concentrate costs 170 rubles per kilogram.

Brief instructions for the installation of penoizol

The big advantage of working with penoizol is that the surface does not need to be leveled before applying it. A thick layer of foam will even out absolutely all defects.

We work with the material according to the following scheme:

- We assemble the equipment according to the instructions.

- We mix in a container all the components of the future penoizol, based on the proportions indicated in the instructions for the equipment.

- Preparing the surface - remove the remnants of finishing materials.

- We make a crate or install logs from wooden beams with a step of 50 centimeters.

- Apply a uniform layer of foam to the surface so that it is flush with the edge of the sheathing or lags. We begin installation from the far end to the near.

- Leave the layer to dry.

- After penoizol hardens, we cut off its excess with a sharp knife.

- After complete polymerization of the material, we lay a reinforcing mesh.

- After that, you can start plastering or painting the surface, if necessary.

Watch the video review of penoizol:

Penoizol appeared on the domestic construction market relatively recently. It has earned considerable popularity due to its excellent thermal insulation qualities, practicality and budget. Penoizol characteristics allow it to be used for insulation of almost any structure.

Penoizol can be insulated outside the walls of buildings and structures, and roof slopes from the inside. It perfectly serves for repair, insulation of already built buildings, which have walls of three layers and voids between them.

Reviews are positive, users talk about pouring material under drywall, siding, fake diamond, in the floors and frames of buildings, as well as in the base of the floor. In this article, we will consider wall insulation with penoizol.

The physical basis of the insulation

Prepared penoizol Penoizol is a liquid thermal insulator based on foamed and polymerized urea-formaldehyde resin.

Prepared penoizol Penoizol is a liquid thermal insulator based on foamed and polymerized urea-formaldehyde resin.

For the preparation of penoizol: a hardener for the resin is added to the soap foam, which is mixed with water.

Before use, urea-formaldehyde resin is poured into it in a certain proportion to obtain the desired strength and density.

Advantages and disadvantages

Benefits:

Disadvantages:

- specialized equipment is required to apply the material;

- the material has low strength;

- when it hardens, it gives off formaldehyde fumes, but after 1-2 weeks this process stops.

Necessary equipment

The following equipment is required for the production of penoizol:

Stages of filling voids and applying to the wall

Drill holes for foam insulation evenly over the entire area. This type of insulation is used to insulate and fill three-layer walls, as well as slabs and other reinforced concrete structures that have many layers and voids.

Drill holes for foam insulation evenly over the entire area. This type of insulation is used to insulate and fill three-layer walls, as well as slabs and other reinforced concrete structures that have many layers and voids.

With such insulation, voids are foamed (filled) between the main and facing walls made of reinforced concrete slabs or bricks.

It is necessary to prepare the wall, that is, remove wood, brick, concrete from it, clean it of dust. The great advantage of the material is that you do not need to level the wall to use it.

It is necessary to drill or drill holes in the facing layer, they should have a diameter of 2.5-3 cm, be located at an equal distance over the entire area. Penoizol is blown into the holes under pressure up to 5 atmospheres.

Thermal insulation evenly fills the space between the walls. It has poor adhesion (adhesion) to concrete and brick, therefore it fills the voids evenly.

High-pressure insulation with penoizol This method is used to fill voids with penoizol that are more than 5 cm, the walls must be made of durable materials that could withstand high pressure.

High-pressure insulation with penoizol This method is used to fill voids with penoizol that are more than 5 cm, the walls must be made of durable materials that could withstand high pressure.

After that, the penoizol layer must be leveled by cutting off the excess. Or remove excess with a dry cloth.

Take into account: professionals advise also to install a reinforced mesh.

To do this, level the material layer and glue the mesh with mounting glue. Or you can apply a thin layer of primer to Penoizol and attach a mesh to it. After plaster the surface of the walls with the usual cement mortar.

Low-pressure insulation of walls with penoizol In order to insulate the walls from the outside, wooden frame or it is built of metal, a fine-grained reinforcing mesh is stretched over it. Insulating material is sprayed under it, after which plaster is applied.

Low-pressure insulation of walls with penoizol In order to insulate the walls from the outside, wooden frame or it is built of metal, a fine-grained reinforcing mesh is stretched over it. Insulating material is sprayed under it, after which plaster is applied.

There is also a low-pressure open insulation with penoizol.

In this case, the thermal insulation is poured slowly and gradually into the niche so that the uniformity of the filling can be controlled.

Watch a video detailing the steps of foaming walls with penoizol: