The best tool boxes - an overview of modern types and the best storage devices for hand and power tools. How to make a box for tools: choose a shape and drawing for self-production Make yourself a folding box for tools

Any responsible owner always keeps the entire instrument in its place. Even small sets should be kept neat and organized. To organize the storage space for tools, keys and other devices, you can independently organize cabinets, tables and boxes with the possibility of transportation.

A wooden suitcase for keys is not only a part of the image of any craftsman or carpenter, but also a functional component. At a certain point, the assortment of the tool reaches such a state that without organizing an orderly storage, the desired key or screwdriver becomes simply impossible to find. In addition, there is a tool that is picky about storage conditions and from interaction, friction and shaking can be damaged and become unusable.

If you need remote repairs, when you need to perform any task in isolation from the workplace, a transport case or tool case will greatly help out, as well as if you want to organize storage, dividing it into sectors for automotive, locksmith, carpentry tools ...

If you need remote repairs, when you need to perform any task in isolation from the workplace, a transport case or tool case will greatly help out, as well as if you want to organize storage, dividing it into sectors for automotive, locksmith, carpentry tools ...

So we need a storage box the right tool, consumables and fasteners. On sale you can find a fairly large selection of various suitcases and boxes, lightweight, convenient and compact. Choosing one for the required tasks will not be a problem, but they cost a lot of money.

Construction and material

Let's first define what types of boxes are:

Before starting work on manufacturing, you need to clearly determine which option you need. And it's worth starting with a complete bulkhead of your instrument, sorting them into groups and sizes. As a result, you can easily choose the required number of boxes on your own.

Material selection

Material selection

- Metal... Quite difficult to make. May need welding and cutting metal structures sheet metal. As a result, such a product will weigh a lot and be difficult to move. But due to its advantages, this option is worthy of attention. In the case of storing heavy and bulky tools, there is less chance of damage to the compartments. But at the same time, it is not suitable for storing carpentry tools. The ideal combination would be the manufacture of a workbench and built-in metal boxes. Making a mobile version on your own, you can use thin sheet metal and copy the design from a factory product. Still very interesting option - a mobile cart with boxes. It is equipped with special swivel wheels for ease of movement. This option has gained its popularity among auto repair shops, garages and vehicle maintenance services. An attempt to independently make such an option will bring a lot of difficulties.

- Plywood... You can make almost identical boxes using plywood. A big plus will be the ease of processing such material.

It's worth starting with a dimensional drawing. The dimensions must be made in accordance with the dimensions of the tool that is planned to be stored in it.

Particular attention is paid to the layout, fasteners and other elements that are taken into account at the design stage.

Toolbox

When creating a wooden tool box with your own hands according to the drawing that we already have, we will need:

- Lumber, board 10-20 mm thick.

- Hacksaw for wood.

- Pencil and ruler.

- Fasteners.

The classic design has no compartments, cells or other functional devices, it is a deep box and a handle for transportation. The shape of the handle is made in such a way for more comfortable carrying, if the tool is unevenly located in the box. The only addition that will be appropriate is an insert in the middle of the box for dividing the container into two compartments. In the left section you can store drills, bolts, nuts, screws and others small parts... On the right - hammers, wrenches and other large items.

If such a box is not planned to be constantly transported, it would be rational to make a sliding cover on top of the box. Parts are cut from the board according to the dimensions from the drawing and fastened with self-tapping screws. To increase the service life, you can paint or cover the plywood surface of the craft with a protective coating.

DIY iron organizer for tools

A case is taken as a basis, consisting of several boxes, fastened together by movable strips, one of which goes into a handle.

- A sheet of iron or sheet metal of low thickness.

- with cutting and cleaning wheels.

- Bolts, nuts, washers for fastening parts.

- Pliers.

- File.

- Anvil.

- Hammer.

Of course, the first stage is work on drawing the drawing and dimensions for the required size of the tool and storage compartments of various supplies and fasteners. In size, you need to take into account the joints and folds, make a small margin of 1-2 millimeters. Marking can be done with a core directly on the iron sheet. After applying the markup to the sheet, proceed to the clipping.

For straight outer cuts, you can use angle grinders, for closed corners - only scissors for metal. We start manufacturing with the main part of the boxes, they are 2 open, 2 closed with organizers and one large, which is the base. The rails are made of thicker iron and are secured with bolts or rivets so that they have free play for folding the case.

Summing up, we can say that everything is possible if you wish. If all is well in your inventory, complete it with compartments and storage containers. If you have a huge number of all kinds of tools, as well as power tools, you should think about creating a large box that will fit everything into itself and help keep everything safe and sound. You no longer have to constantly look for the right key or screwdriver, because you will have everything in its place.

There are many professions in which they apply different kinds tools. Most often, tool boxes are purchased for their storage, but sometimes high-quality storage is easier to do with your own hands.

If you are interested in this or that kind of craft, and you do not sit at home with folded hands, of course, you have a fairly large number of tools. To ensure that your tools are always at hand and safely stored, they need to provide a security system in the form of a separate closed space called drawer for storing tools.In addition to safety, the use of such a box will greatly help in work, since the filling will be neatly sorted into compartments and in the future you can find the necessary device “blindly”. This device is also needed by car owners, or rather owners of trucks and gazelles. The box must be well secured in the car. This means that when making it with your own hands, you need to think carefully about where it will be in the car and how to fix it there.

If you are interested in this or that kind of craft, and you do not sit at home with folded hands, of course, you have a fairly large number of tools. To ensure that your tools are always at hand and safely stored, they need to provide a security system in the form of a separate closed space called drawer for storing tools.In addition to safety, the use of such a box will greatly help in work, since the filling will be neatly sorted into compartments and in the future you can find the necessary device “blindly”. This device is also needed by car owners, or rather owners of trucks and gazelles. The box must be well secured in the car. This means that when making it with your own hands, you need to think carefully about where it will be in the car and how to fix it there.

Decide on two criteria:

- will you only store tools in it, or do you need it for ease of transportation?

- what sizes of tools do you intend to store in it?

Classification of boxes

By body material:

- plastic - light in weight, easy to use and easy to transport;

- metal - much heavier than plastic, but at the same time much stronger, more stable, have a more rigid structure, cannot be large sizes due to the severity of the metal;

- galvanized metal-plastic - lightweight, durable and spacious, suitable for both storage and transportation professional tools... But all these advantages determine the corresponding price - it can range from $ 150 to $ 500 and more.

- wooden - the most affordable material for making a tool box. Moreover, it is easier to do it with your own hands from this material, or rather from plywood 10 16 or 18 mm.

By type of stored instruments:

- hand tools - as a rule, they are represented by one large compartment for large tools (screwdrivers, hammers, keys) and 2-3 small ones for smaller tools;

- an electric tool is a case functionally designed to store and move a specific power tool. Most often it has one main compartment for the device itself and several recesses for equipment.

- organizers - boxes designed to accommodate a large number of tools of various sizes. They have many compartments, models with modular partitions deserve attention, which for the convenience of the owner can be rearranged from one place to another.

- professional tool - a special type of case with specific seats for specific tools that are more resistant to drops and adverse environmental conditions.

- non-professional tool - represents boxes of both small and fairly large sizes with many compartments, and niches for various kinds of tools, often these are cases in the form of bags.

There are many companies for the production of tool boxes, such as stanley, fit–american firms, keter - no less popular Israeli company, Spanish company tayg, german Kroftand many others, differing in quality and price of products.

As an alternative to all these firms - the ability to make a tool box with your own hands. Thus, you can save on cost and get a completely competitive option that meets your exact requirements.

Types of boxes

Homemade toolboxes are mostly made of wood and come in a variety of shapes. Popular and easy to manufacture boxes of the classic form - "basket". in the second and third place - a box in the form of a chest - a container, and in the form of a case.

|

|

|

Materials for making a tool box

- wooden boards 15-25 mm thick

- round wooden rod of the desired length

- self-tapping screws, wood glue, sandpaper for cleaning surfaces

- a set of tools - grinder, electric drill, jigsaw, screwdriver

- measuring tools - ruler

- screwdriver, hammer

Manufacturing steps

Using this technology, it is possible to make boxes of more complex designs, creating by means of partitions required amount compartments and niches.

Using the same technology, it is possible to manufacture a closed box, which is more reliable and convenient for transporting tools.

Additional steps in the manufacture of a box with a lid

For self-made popular now boxes-transformers you will have to break your head more, but it is quite possible to implement this idea.

To do this, using computer programs it is necessary to develop the design you want, but to translate it into reality will help you with a set of necessary elements that can be purchased in special stores. The number and complexity of the selected elements depends on your requirements for the box. Assembly can be done on wooden baseusing aluminum strips and corners. Fasteners are made with rivets.

If you are a purposeful and creative person, then the process making tool boxwill not be difficult, but seeing the fruits of this work, you will increase your self-esteem and save budget funds.

This article is about how to make a wooden toolbox. If you have a lot of tools and want to keep them tidy, the best thing you can do is create a simple wooden box. From our experience, we find them to be very useful as they are lightweight, durable and offer a lot of storage space for tools. Don't forget that you can adjust the size and design to suit your needs.

The main components of the tool box are made from 20mm boards, as they have a beautiful appearance, and very durable. In addition, we recommend that you glue the joints and fasten everything yourself with cuts. Try to screw in the screws as symmetrically as possible.

Upon completion of the assembly, it will be necessary to sand the entire surface of the box. Make sure all edges are smooth. Otherwise, you could injure your hands on the sharp edges. Also, be sure to check that all screw heads are flush with wooden surface... Remove dust and shavings before painting.

What you need to make a wooden toolbox

In order to make a wooden toolbox, you need the following:

Materials

Tools

- protective gloves, glasses;

- ruler;

- crayon, tape measure, level, carpenter's pencil;

- and drills.

Advice

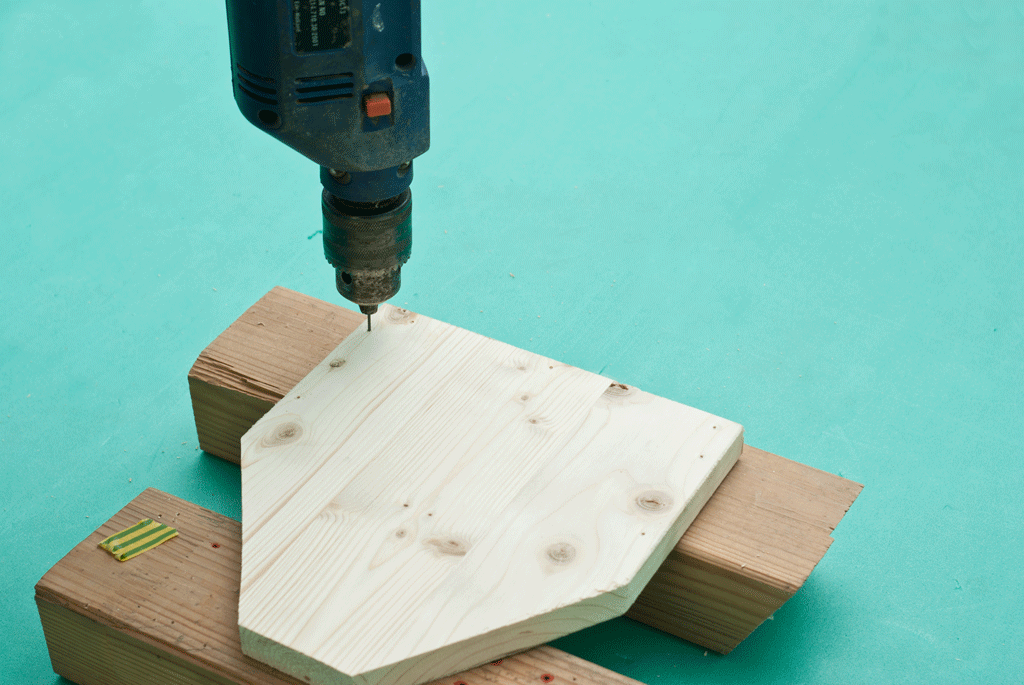

- Pre-drill holes in the wood components before tightening the screws.

- Make a handle from a cylindrical stick.

Time

- 1 hour

Drawer decoration

Making a basic wooden toolbox is one of those projects that can be done in less than an hour. But it can make your life easier, especially if you work with tools a lot.

Smart Tip: Add some glue to the joints before joining the pieces. Remove excess adhesive immediately with a dry cloth, otherwise it will be difficult to remove once it dries.

The first step in the project is markup. As you will see in the next step of the project, we will be using 1 × 8 boards to make the toolbox. Therefore, you should use a carpenter's pencil and a square ruler to mark the lines on the wooden boards.

In order to obtain accurate cuts, we recommend using a jigsaw or a good circular saw. Make sure the saw has smooth teeth, otherwise it may tear off the edges.

Smart Tip: Also, make sure that the blade goes exactly along the cut line before cutting.

In the picture, all the components required for the box. Circular machine can simplify work as many cuts need to be made at an angle.

You must use this blueprint when making components for the crate. Make sure you double check all measurements, otherwise the components may not match.

After creation wooden parts, you need to drill holes around the edges. As you can see in the picture, you need planks on wooden barok to prevent surface damage. Drill three holes in the bottom and two holes on the sides.

Smart Tip: If you are inexperienced in woodworking, you should draw landmarks for the pilot lines. Space from the edges to prevent splitting of the wood.

If the edges of the bottom are not smooth, you should sand them thoroughly with 120-grit sandpaper before assembling.

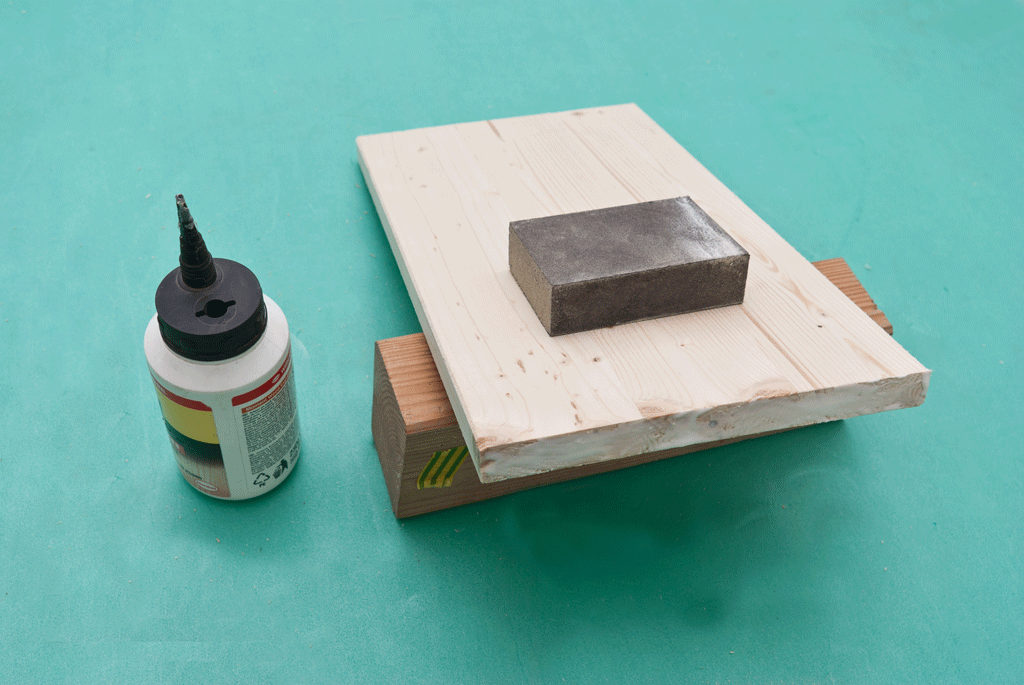

Cover the lower ends with wood glue to strengthen the connection. Remove excess glue with a dry cloth, otherwise you will take time to clean it.

Press firmly on the ingredients and leave for half an hour. If you use good glue, it will hold the joints well together.

However, screw the screws into the drilled holes anyway.

In order to get a solid construction, we recommend using self-tapping screws. Work carefully to prevent damage to wood components.

Smart Tip: Line up all parts before twisting. As you can see in the picture, the edges should be straight.

After installing all the components together, the tool box should look like the one in the photo below.

Make a handle from a cylindrical wooden rod... Handle diameter approx. 20-25 mm.

Smart Tip: Use a ruler to cut the bar to the desired length.

Add a little wood glue to both ends of the bar before setting it in place. Then drill a hole and tighten the self-tapping screw. Hold the handle while tightening, otherwise it may budge.

Smart Tip: Leave about 15mm from the top edge to the wooden handle.

Remember to smooth the edges of the wood components with sandpaper.

Smart Tip: Remove dust and chips from the drawer before painting.

Then completely sand the entire surface of the box with sandpaper.

Smart Tip: Apply several coats of paint, varnish or stain to enhance the appearance of the wood and protect materials from decay.

If you want your box to have the same dimensions as in our article, we clarify that 1 inch equals 2.54 cm.

Hello everybody!

Today, a tool box is a very indispensable thing for every owner. Most of us have a lot of different tools that we may not use very often, but nevertheless, we store it, since more than one repair is not complete without it. In order for the tool to be in one place and to be conveniently transported, we use special boxes. Often we just buy them at the nearest store, the assortment and variety allows us to do this. But why not make it yourself? The manufacturing process is not too complicated, anyone should cope, especially with a hand-made thing, which is much more pleasant to use than the purchased option. This article will describe 4 different ways manufacture of boxes, photo report is attached.

Let's start making!

Manufacturing method No. 1

We need:

Material

Plywood;

- pine board;

- nails;

- wood glue.

Tool

- drill;

- hammer;

- chisel;

- manual frezer;

- ruler;

- pencil;

- roulette.

The first step is to find required material, for this plywood or board trimming is suitable. Further, according to the presented drawing, you need to make a markup, then cut out all the parts of the body. It is necessary to make special grooves in which the partition will be placed, for this we use a hand-held milling cutter, or another available tool.

The diagram shows the following body parts:

1 - wall (2 pcs.);

2 - sidewall (2 pcs.);

3 - bottom;

4 - groove along the thickness of the partition and a depth of 1 / 2–1 / 3 of the material thickness

When everything is ready, all elements of the box body should be sanded. Next, we assemble the body together, fix the parts with wood glue, and then additionally fasten them with small nails.

Now we make a partition for the box, cut out a special handle, for this we use a jigsaw.

When the partition is ready, grease the grooves with wood glue and install it in its place.

Next, we make overhead handles from the boards, with the help of a planer we round the corners. Then we make tool holders from the rails, use a jigsaw, and a drill. The holes will be used for screwdrivers, and pliers, etc. will be installed in the square cutouts. tool.

To prevent the box from getting dirty, and to protect it from the environment, we cover the surface with varnish. As a result of the work done, we get such a homemade box.

Manufacturing method No. 2

Drawer stool

Material

Plywood or OSB;

- wooden beam;

- self-tapping screws;

- wood glue.

Tool

Cutting tool available;

- screwdriver;

- ruler;

- pencil;

- roulette.

We take the existing plywood sheet, mark it on it, and according to the presented dimensions we cut out the cover (Fig. 1), then the longitudinal sidewalls (Fig. 2) and the sidewalls (Fig. 3).

Then we take a wooden beam with a section of 40x50 mm, cut out the handle, and 4 legs with bevels at the ends at an angle of 15 °.

Next, we assemble the structure together, use self-tapping screws as fixing elements.

Parts layout:

1 - cover;

2 - king;

3 - handle;

4 - leg;

5 - sidewall.

When everything is ready, using sandpaper or a grinder, round off the sharp corners and clean the surface. Next, you can apply a protective coating.

The end result should be such an unusual toolbox, which, if necessary, can be transformed into an ordinary stool, for this it is enough to turn it over and put it on its legs, with the help of it it will be convenient to reach the place we need, at a time when growth does not allow do it.

Manufacturing method No. 3.

Box for the young master.

Does your child love tinkering? We offer together with him to make a small box where he will keep his favorite tool.

To make a box with our own hands, we need the following

Material

16 mm boards;

- round wooden beam;

- self-tapping screws;

- wood glue.

Tool

Cutting tool available;

- screwdriver;

- ruler;

- pencil;

- roulette;

- clamps.

First you need to take the existing boards with a section of 16 mm, then we make the markings according to the dimensions provided, after which we cut the wood into the components we need.

The drawing shows the following details:

1 - sidewall;

2 - bottom;

3 - handle;

4 - handle stand;

5 - holder.

Using sandpaper, we grind the surface and remove sharp corners. When everything is ready, we begin to connect all the parts to each other, first you need to connect the bottom and sidewalls, then we put vertical racks along the marked lines and at the same time we put a horizontal handle.

We fix everything with glue and self-tapping screws. Then we install special screwdriver holders.

Now you can paint, choose the color and coating at your discretion.

The toolbox is ready.

Manufacturing method No. 4

The next version of the toolbox is well suited for carrying various equipment that we need, its appearance will be distinguished by its solidity and reliability.

To make a box with our own hands, we need the following

Material

The board is not thicker than 12 mm;

- self-tapping screws;

- joiner's glue;

- a pen;

- corners 8 pcs.;

- latch 2 pcs.;

- loop 2 pcs.

Tool

Cutting tool available;

- screwdriver;

- ruler;

- pencil;

- roulette;

- clamps.

For the manufacture of the box we use such wood as: pine, linden or poplar. The most optimal board thickness will be 12 mm.

Next, we make the markup, according to the indicated dimensions in the drawings, and then saw it into its component parts, as shown in the photo.

The entire list of required parts.

In order to make sure that the wood was cut correctly, you need to put all the parts into a single box.

First, we assemble the bottom part and the lid of the box, for convenience we use clamps and corner clamps. We fix the details with each other with wood glue.

Then, using a drill, we drill a hole for self-tapping screws, we make holes countersinking.

It's no secret that good master starts with a good instrument. And any tool must be carefully stored. In this article, we will talk about how to make a tool box with your own hands. At the same time, use in your work available materials.

In addition, there is a tool that cannot be stored in bulk. For example, files or drills. From friction against each other, these objects become dull. And even during work, a carelessly lying tool forces you to spend time looking for it.

So - we need a storage box the necessary devices, consumables and fasteners.

Making a tool box yourself

To begin with, let's decide on the purpose and its functionality. What he is and what he should be.

Portable tool box

A small number of items are placed in it, usually the equipment corresponds to the type of work. Such a box must have a strong lock so that it does not accidentally open during transportation. During movement, the tool should not dangle inside, each element has its own niche, and, if possible, is fixed.

Stationary tool box

True, this concept is relative. It's just that such a box is not carried with them to the place of work. It can be moved neatly around the workshop.

This design does not provide for tool holders, but they are arranged in compartments and, as a rule, are divided into groups.

Specialized tool box

Unlike the first two options, such a storage is intended for a specific group of devices. For example, wrenches, or a set of bits and drills for a screwdriver. In addition to the main content, maintenance materials are usually placed in such boxes.

Such devices are more convenient than universal ones, but they will require several pieces.

Therefore, before manufacturing, you need to decide which option you need. First, take an inventory of your tools. Arrange them in groups and sizes. And it will immediately become clear to you how many boxes and what size you need them.

How to make a tool box

Choosing a material:

- Metal tool box. It is not so easy to make it. Welding may be required. A self-made steel box will be too heavy to carry, but it also has the advantage that a heavy and bulky tool will not break cells as quickly. You can not stand on ceremony with the accuracy of laying a 38x52 key weighing half a kilogram. The weighty set of caps will not break through the wooden bottom.

But for devices with sharp sharpening, or files - it will not work. The best option - installation of such a box under the workbench. It is only necessary to install a stopper so that the heavy pallet does not fall on your feet. When making a mobile or portable version, you can use thin sheet metal and make a box following the example of factory designs.

But for devices with sharp sharpening, or files - it will not work. The best option - installation of such a box under the workbench. It is only necessary to install a stopper so that the heavy pallet does not fall on your feet. When making a mobile or portable version, you can use thin sheet metal and make a box following the example of factory designs. - Another option to follow is an iron cart with boxes for tools and accessories. This design is popular in car services. For a home workshop, this is perfect option, only manufacturing is fraught with technical difficulties;

- If you need the same strength and functionality, try making a plywood toolbox. The strength will decrease slightly, but it is much easier to process such material. Before making a box with your own hands, draw the drawings. The craft should be neat and match the dimensions of your instrument. For the main body, choose a thickness of 8-10 mm. Buy wheels (if you need them) at a hardware store. All connections must be screwed. The nails will loosen quickly. The joints are additionally coated with PVA glue. Boxes with cells can be made of 6-8 mm plywood. The frame walls of the material are thicker, the bottom and cells are thinner. If the tool is not too heavy, choose hardwood bars as guides. Metal corners can be screwed on.

note

If you have additional funds, buy roller guides from a furniture accessories store.

Then you will not be afraid that the box will fall on your feet. Wide and low pallets are perfectly divided into sections by internal partitions. The more there are, the easier it is to sort the tool and consumables according to their intended purpose. DIY toolbox - provides ample opportunities for creativity;

Then you will not be afraid that the box will fall on your feet. Wide and low pallets are perfectly divided into sections by internal partitions. The more there are, the easier it is to sort the tool and consumables according to their intended purpose. DIY toolbox - provides ample opportunities for creativity; - DIY wooden box. This is a classic in joinery. Drawings of such a portable storage facility were published in the "Young Technician" magazine 50 years ago.

For manufacturing, you will need a board 10-20 mm thick and a hacksaw for wood. That's all. Therefore, despite the many modern designs, the masters of the old school choose this particular option. The classic design does not provide for compartments or other functional devices. Just a deep box and a comfortable full-length handle. This shape of the handle is of practical importance. If the weight of the tool is unevenly distributed, you can always find the center of gravity point, so it is always convenient to carry the box;

For manufacturing, you will need a board 10-20 mm thick and a hacksaw for wood. That's all. Therefore, despite the many modern designs, the masters of the old school choose this particular option. The classic design does not provide for compartments or other functional devices. Just a deep box and a comfortable full-length handle. This shape of the handle is of practical importance. If the weight of the tool is unevenly distributed, you can always find the center of gravity point, so it is always convenient to carry the box; - A practical addition is the insert section with its own handle, which occupies 50% of the height of the drawer. This insert is used for small tools (screwdrivers, awl, small keys) and consumables (drills, screwdriver bits, etc.). It can be made from plywood or thinner wood. The lower (main) compartment contains a large tool. Hammer, drill, plane, large pliers;

- If the wooden box does not require constant carrying, you can make a box with a sliding lid. There are several such containers of the same size. They are placed on shelves, an inventory is made at the end of the contents. A completely different structure can be made of wood and plywood. Vanity box (only without mirrors).