Making risks. Technology manufacturer of barrels. Self-blank riveting for

You can choose to build a bathroom traditional option - cut down a little or build a pair frame technology. Which is more attractive and the bath looks like a barrel made with their own hands from specially trained boards. Since the method of assembling the purchase facility is interested in many homeowners, we suggest considering the procedure for manufacturing in this article.

Selection of design and sizes

The construction is similar to the barrel not only externally, but also constructively. The construction consists of the following elements:

- face walls round shapesplit from tightly fitted boards - the analogues of the bottom and lids of the barrel;

- side walls collected from longitudinally laid thick boards with special recesses (following the sruba);

- external ties made of steel strip or cable resembling barrel iron hoops;

- stands for horizontal installation of the assembled body on Earth;

- elements of internal arrangement - furnace, shelves, partitions with doors (if necessary).

Steam, washing and pre-tribades in the form of a classic round barrel

Reference. There are also more complex structures made in the form of a rectangle with rounded corners or an oval shown below in the photo.

First of all, it is necessary to determine the project and layout of bathrooms - the future sizes and the basis of the structure depend on this. Consider an important point: the side walls are gained from one-piece boards made specifically for the bath, so the length of the structure directly depends on the lifetime length.

The design and internal layout of the barrel is developed depending on the chosen type of bath and other wishes of the homeowner as follows:

The newcomer, who decided to independently build a bath in the form of a barrel, is not recommended to start with large structures equipped with several inner partitions. Make a one-room sauna with a length of 2 m - if desired it can be immersed on the trailer a passenger car And take out rest near the reservoir.

Timber blank

Brux and boards for a bodily manufactured in the form of a barrel must be peaked out of hardwood - Aspen, Lipa, and so on. The use of cedar and larch, resistant to temperature differences and moisture, is allowed from coniferous rocks. Pine and spruce, with a strong heating, highlights the resin, whose drops are capable of burning in pair people.

Council. If the selection of wood is limited only to coniferous rocks, pick up boards without knots, which are sources of resin discharge on the surface of the body.

To make a bath type "barrel", take such timber:

- bar with a minimum cross section of 10 x 10 cm for stands;

- the board with a thickness of 45-50 mm and a width of 10 cm is used to assemble end and side walls;

- wooden door 0.7 x 1.8 m with a box (you can buy ready-made or make a 50 x 50 mm and 2,5 cm bruques thick);

- lumber for the manufacture of regiments and a lattice pallet.

The number of boards on the end walls of the barrel is calculated as: the area of \u200b\u200bthe circle is determined, the value obtained is divided into the width of the product and is multiplied by the reserve coefficient of 1.2. Do not forget to add bars - power jumpers, binding boards among themselves during the panel assembly.

The timber side of the lateral skin is considered the length of the circumference, divided into the width of the board. Use the stock ratio, since the forest must pass the grooves and ridges on the woodworking machine.

Note. It is easy to find ready-made kits for assembling baths - barrels of various dimensions and layouts. But often the quality of the specified products does not correspond to their value.

What else will need during the construction of a circular bath:

- metal ties - steel cables or stripes;

- fasteners - galvanized screws and nails;

- compositions for the outer and inner processing of wood - antiseptics, varnishes;

- materials for the manufacture of roofs - duncan, plywood, bars and roofing (common options - bitumen tiles or professional flooring);

- bath furnace of the appropriate power calculated by the volume of the steam

- chimney pipes - sandwich;

- special lamps and bath switches, non-combustible cables.

If it is supposed to use a barrel year-round, it is worth making outdoor insulation. Suitable thermal insulation material - mineral wool, polymers are not recommended.

Wood processing

Since the walls of the baths are connected in a special way - by the type of log cabbage, all the boards need mechanical processing Machines on the machine, cut off by manually semicircular grooves unreal. The developer needs to contact the woodworking workshop and provide sketches with the parameters of the blanks. The exact dimensions of the ridges, grooves and profiles cutters are indicated in the drawing.

To facilitate further construction works, Turning the billets to handle in advance according to the instructions:

Council. The surface of the blanks coming out and inside the barrels, cover different protective compositions. From the inside, apply a special means for baths and steam.

After dyeing, fold the boards to sleep into the stack, laying thin strips between the tiers. How to bet preparatory work, Look at the video:

Production of end walls

As mentioned above, the barrel - the bath is made with their own hands from two (minimum) edge elements of the round shape connected by profiled plating boards. Therefore, construction begins with the assembly of the ends of the barrel on the shield technology.

Place 2 supporting timber on a flat platform and start collecting the rear throat wall in such a sequence:

Council. Binding the billet into the shield is not necessarily two long jumpers. Put 4 crossbars shorter and closer to the edge - the product will look aesthetically.

When assembling the groove of each subsequent timber, it is put on the comb of the previous one, as the builders of chopped houses make. This method of compound prevents sediment ingestion. Boards Customize tight, if necessary, use clamps and folding.

The front wall is made in the same way, only the base serves door box. It is twisted by self-reserves from BRUSEV, pre-secure on the stands by clamps and pulling the diagonal of the roulette. To draw a circle, adjust the temporary board on which the center is located.

After the sinking of the surplus, polish the ends of both products and install the door. The extreme walls of the wall will not prevent additionally to secure long furniture screws screwed into the neighboring bars of the shield. How the round walls of the barrel are made - Baths, look at the video:

Bath assembly instructions

The construction is required to assemble at the place - it is quite cumbersome to move. But first it is necessary to make stands - legs, located under the extreme walls and partitions. For the manufacture, maximize the cropping of materials remaining after assembling the front and rear wall. One of the design options is demonstrated in the photo.

Installation of the bath barrel is made in this order:

Important moment. A variant of the traditional Russian bathakes with a washer is installed under a slight bias in the direction of the rear wall. At the bottom point of the floor, the water removal hole is drilled.

The finished housing of the barrel should be protected from precipitation so that the top of the bath is smaller than the wet. It is recommended to apply a budget way:

- Across the housing type flexible wooden strips with cloves with an interval of 0.5-0.6 m.

- From above to the planks pinned sheets of thin plywood.

- The improvised roof base is covered with bitumen tiles.

If you need to produce insulation, the duch is nailed to the body in several layers - the gap between plywood and the outer surface of the barrel will increase. There you can lay out mineral WatLocked the diffusion membrane. Bani assembly procedure is shown in detail in the next video:

Work on the arrangement

At the end of the installation, go to internal arrangement barrels. The following works remain in the bath:

- Make a vent hole covering in the rear end.

- Install the oven using a metal stand. The segment of the wall behind the ovens protect the staple materials - roofing steel or mineritis plates.

- Arrange the chimney from the tube sandwich by doing the hole in the ceiling. How to mounted chimney pipes, read.

- Make the shelves and floor ladder (lattice pallet), attach items to the walls.

- Run the wiring, install the bath lamp and switch.

Under the barrel - the Russian bath is preferably to dug apart for water drain through the hole in the floor. There is another way of drainage - connect the flexible nozzle to the drain, departed to the livnevel chute or another place.

Conclusion

If you decide on independent manufacture Baths - barrels, pardize patience and plenty of free time. The author of the videos presented here spent on the assembly from zero about 1 month. Add temporary costs of the solution of unforeseen delays and problems associated with the lack of experience. There is a way to reduce construction deadlines - order a ready-made set of masters, and only install only installation.

Designer engineer with experience in construction for more than 8 years ..

He graduated from the Eastern Ukrainian National University. Vladimir Dalya in the specialty "Equipment of the Electronic Industry" in 2011.

Related records:

The main outer sizes of the barrels are:

- height;

- diameter in a bunch;

- head diameter. Innutrine sizes of barrels are:

- height between bottoms in the center;

- diameter in a bunch;

- diameter from Donov. Between the height of the barrel and its diameter in the bunch and between the diameters in the bunch and in Donites there are certain and natural relations, the observance of which ensures the strength and impermeability of the product. From the selection of these relations, the shape of the barrel depends: the smaller the difference in diameters, the closer the shape of the barrel to the cylinder; The greater the difference between the diameters of the DonEv and in the bunch, the more convex barrel. In cylindrical barrels intended for transporting fish products, height is less than diameter.

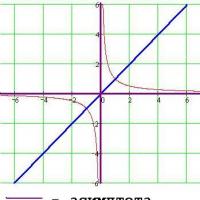

If you take the head diameter per unit, then recommended ratios, proven by long-term practice, for the main sizes of barrels will be the following:

- head diameter d \u003d 1.0

- diameter in a bunch of d \u003d from 1, 10 to 1.25

- height H \u003d from 1.10 to 1, 50 for liquids such as beer, wine, etc., the most convex barrels are used, which have the greatest sediment of the hoop and screed, which is especially important when drying the barrel and re-sediment by the hoop. .

For the manufacture of a barrel of a certain container apply the following external and internal dimensions (mm).

- For the manufacture of barrels requires riveting of the following sizes (mm)

The bulk holes are drilled or cut before inserting a bottom. In the bulk bar, intended for drinks, in the widest riveting hole, the hole is drilled by a flat drill with a side edge mounted on 1 - 2 degrees. Flat drills different sizes It can be made of a saw blade with a thickness of 1.5 - 2 mm. To obtain the records of the desired size, the saws on the line of the line are delivered deep risks with a scraper or file. You can apply a cutter of solid steel - COGOT. From the rod with a diameter of 8 mm, the holder is pulled out. From one of the ends of the rod, they cut down the axis to the depth of 14 mm. At a distance of 7 mm from the edge perpendicularly, the cross-cutting hole is drilled. The same hole at the corresponding distance is drilled and on the plate. The plate is connected to a rivet with a rivet or a screw for which the threads are cut. The drill is sharpened and insert into the cartridge drill.

Due to the beveled drill edges, the hole in the riveting is conical. Drilling is stopped when the cutting part of the drill will be released on the opposite side of the riveting.

The plug or plug cut out, as a rule, from the linden. The linden wood is soft, homogeneous, does not swell and does not dry. These are those properties that are needed for a wooden cork, as it should not only reliably close the drain hole, but also easily removed from the sleeve.

In the finished barrel pour water and check if it flows. Water can only leak over the first minutes. Then the wood will swell and close the gaps tightly. Most often, water is seeping between the Don and Rivets. If the barrel flows more than 30 minutes, it is necessary to cross it with a jarry grass.

Barrels made from linden, aspen, alder or ate enough to scream with boiling water. In oak barrels contain many tannins. Therefore, it is processed specifically. First for three weeks they are poured cold water. A day later, the water change and watch it out. In the first days, the water will be painted in light brown, then it will become lighter. When water becomes transparent and clean, it is replaced with a warm aqueous solution of drinking soda. For the preparation of a solution of 20 g of drinking soda is dissolved in 1 liter of water. After 30 minutes, the barrel was washed first hot water, then cold. After this processing, it can store any liquids in it.

Barrels made from linden, aspen, alder or ate enough to scream with boiling water. In oak barrels contain many tannins. Therefore, it is processed specifically. First for three weeks they are poured cold water. A day later, the water change and watch it out. In the first days, the water will be painted in light brown, then it will become lighter. When water becomes transparent and clean, it is replaced with a warm aqueous solution of drinking soda. For the preparation of a solution of 20 g of drinking soda is dissolved in 1 liter of water. After 30 minutes, the barrel was washed first hot water, then cold. After this processing, it can store any liquids in it.If it is necessary to measure the amount of non-standard barrel, it is necessary to take glass or metal dishes, for example, a 12-liter bucket or 1-2 three-liter banks and pour into a certain dish in the barrel. In addition, it is quite often a formula for which the volume of the barrel \u003d 3.2 HRR, where H is height, R is the radius in the widest part and R radius in the narrow part of the barrel.

Knowing the dependence between the main sizes of the barrel and the formula for determining its internal volume (capacity), it is possible to install the sizes of the barrel on the specified capacitance and to set its container from the sizes of the barrel.

According to the same data, it is possible to determine the volume of wood in the barrel, which is equal to the volume of wood in the core of the barrel plus the volume of the wood of both donings. In barrels for food products It is not allowed to use pine wood for barrels under foam oil, frozen berries, fruits, dairy products, margarine, kitchen fats and canned fruits and vegetables for preventing these products from possible transmission of specific resinous smell.

For food products that can be recycled, washed, harvested or passed before use in food, for example, for saltin, intestines, etc., pine barrels are allowed.

Pine barrels made as carboards, in front of the rapidation exposed inside the burning with steaming and washing or covered inside enamel. Any barrel must be made of one rock wood, since in this case the riveting of the island and the DonEv operates in the same conditions, having resistance to efforts to compress them, bending, as well as dry drying and wood swelling.

The collected barrel should have the right form - without distortion, depression and bulges. Dona must be inserted so that the champers are tightly entered into a helical groove circle throughout his depth. Rivets of the upper and lower donings must be located in one direction. The end hoops must be packed into a level with riveting ends; The locks of all the hoops must be located on one riveting is the island.

To drain the liquid products in the barrels drill 1 - 2 bulk holes - cylindrical or conical. For example, in an oak beer, a bulk hole with a diameter of 50 mm drove in one of the riveting, into which the metal sleeve is flush with a riveting, which is inserted by a wooden tube of conical shape. The other hole with a diameter of 25 mm is drilled and burning in the middle of the length of the upper riveting bottom at a distance of 50 mm from the island. The holes are drilled in rivets with a width of at least 100 mm, the plugs are made of soft rocks.

In the manufacture of food barrels with bulk holes, the outer diameter of one hole must be 40 mm, the second - 20 mm, the inner diameter of the tapered holes should be 5 - 7 mm less than the outer. The plug should be 40 mm long, of soft rocks of soft rocks, without bitch, chips and cracks. The outer diameter of the plugs should be 5 mm larger than the diameter of the opening, internal - by 2 mm less than the hole diameter.

The barrel made for food products should not have an outsider, not characteristic of wood, from which it is made. Inner surface Must be clean.

Checking the barrels in the absence of leaks are produced by filling with water through the sleeve opening or through the open bottom. Fully poured water barrel rolls in different directions.

Barrels with a capacity of 15 liters and above are made. For example, for fish 15 l, 30 l, 50 l, 100 l, 120 l, 150 l, 250 l, 300 l; For grape wines with a capacity of 50 l, 100 l, 150 l, 200 l, 250 l, 300 l, 350 l, 400 l, 450 l, 520 l, 600 l, etc.

Made wooden barrel with their own hands will allow not only to save, but also get a high-quality elegant product. Wood barrels were used by our ancestors for the soles, the manufacture of alcoholic beverages and water stock, which proved their versatility. Therefore, they have been successfully applied to this day. How to do wooden barrelSo that she was a durable and did not proceed? What instruments and skills are required to make a barrel at home?

If you are resolutely configured to achieve the goal and are not afraid that you will have to refine the product to the desired state, you can embody a dream and make a wooden barrel yourself. Bondar is a severe profession that came to us from past centuries. The masters of this craft today are not less, and high-class specialists in the manufacture of barrels are even smaller, therefore barrels in free sale - rarity, and the cost of the product is not for everyone for pocket.

Tools

To make your first barrel or a small barrel, you need to prepare a place in which it will be convenient to work, tools and suitable material. In addition to the joinery set required for the manufacture of a barrel with their own hands, you need to purchase Bondar devices:

- carpentry workbench, fitted for the manufacture of barrels;

- long Fuganok and Circular Gorbach Circle;

- the device for planing edges on the boards, the barrel will be assembled;

- equipment for tightening rivets (pillars, chain screed and frame-gate);

- babel, stroke, bracket;

- patterns and patterns of their own production;

- clamps of wood, metal (for assembling the head of the barrel);

- the usern is a device that allows you to cut a helical groove where the bottom part is inserted.

It should be understood that to acquire these tools, wood and fixtures on the market is quite difficult, since almost all bondari make machines and layers on their own taking into account its growth. This is done by samples, no instruction will help.

What you need to know

The main difference of cooled products is an assembly of pre-prepared wooden boards (rivet). The size and shape of the barrels are completely dependent on pre-prepared boards, the configuration of which is set by the Bondar. And the initial quality of the tree barrels completely depends on the chosen wood. For this reason, the master is not enough to be a tool. It is necessary to know the subtleties of each tree of wood, of which wooden products will be manufactured.

An experienced master will not make a barrel under honey from oak blanks, because he knows that in such a capacity honey quickly acquires a completely different fragrance and will darken. But the barrels from the oak can not be found to be replaced to excerpt wines and brandy.

The second element is the hoop that is tightened by all components of the barrels. It is thanks to the hoop that the water does not seep through the joints between the boards. It can be made of metal or wood. As the experience of masters shows, metal hoops are much stronger, and less time is spent on the manufacture than on wooden. But some masters still give preference to a wooden hoop, giving barrel a more beautiful look.

Production Production Details and Principle

Many believe that it is very difficult to become a bondaram-an amateur, and dreams are not embodied. But if you are not accustomed to retreat from your decisions, then you need to decide which options will be your first job.

There are 3 types of products: conical, cylindrical and parabolic. Each corresponds to a certain type of rivet:

- Products made in the form of a quadrangle, the long sides of which have a view of the parabola, are used for dishes with convex edges: barrels or barrels.

- The diagram in the form of a cylinder is simple. It is easy to make and combine the hoops of one diameter, but when drying wood in such a design, the rivets cease to perform their functions. This is the main reason why such containers are practically not manufactured.

- The shape of an elongated trapezium allows you to get durable dishes when riveting riveting. Therefore, this type of product is often suitable for making pads, ears and other dishes.

It is better to stay on a simple small barrel as an experimental sample.

Many are interested in how ordinary tube do. Kadushka is the simplest Bondar product, achieving the result in its manufacture, you can go to more complex views of the dishes, for example, make a wooden barrel with your own hands.

The principle of creating a product consists of such steps:

- production of blanks;

- assembly of dishes;

- finishing work.

The reliability of the structure will depend on the quality of the riveting of the riveting, so the appropriate billets from the deck of a spinal tree, powder with an ax. For the barrels the most common version of wood is oak, since it easily splits in the radial direction. Process of rivets from different breeds Trees are practically no different, a single-row or two-row method of inqualing is applied. For large decks, a two-row method is used, and for thin chocks only one-row is used.

The order of riveting rivets is as follows:

- Kage must neatly split in half so that the split line is strictly in the center of the workpiece.

- Each fell need to split two to get 4 equal parts.

- Next, you need to split the wood for the workpiece once again in half to get 8 equal parts. Usually for small chumbs this is quite enough. It is 1/8 part that will become a procurement of riveting.

- If the ridge is thick, a two-row rinse is applied, i.e. Each of the 8 parts split into 2 equal parts along the annual rings.

- The resulting lamps need to split in the radial direction. As a result, 1-2 blanks of smaller size and 2-5 are for billets of large parameters.

- Next, the wedge-shaped protrusions and young wood from the bark should be placed. Only after that you can carry out the drying of the workpiece in the open area or resort to artificial drying.

Making rivets

To make rivets from the harvested material, you should pre-prepare the drawings and a specific product template in accordance with the desired form. To get ready-made rivets, you will need:

- Perform markup.

- Make black processing of each of the billets. Namely roundate the outer surface, to mock the edge of the ax.

- Perform a finishing processing using a plane, constantly controlling the result pattern.

- Starting the inner part of the billet with a hunchbole.

- Slide the narrow edges, after which it is to align their surface by Fugansky.

In the process of making barrels, the bondaru has to independently do tightening hoops. The easiest way to get the hoop from steel tape. To do this, it will be necessary to determine the diameter of the container and add a double bandwidth to the resulting digital. Next, with the help of a hammer, you must bend the ribbon ribbon, drill 2 holes and secure them with rivets. For the manufacture of a small barrel, 2 wrap will be needed, which will correspond to the diameter of the upper and lower parts of the product.

Build bottom and its installation

- Sathed the edges of the boards, fix on the workbench and divide the radius on 6 parts.

- Within the circle, mark the vehicle installation locations.

- Pull out the boards. In the edges, drill holes, drive off wooden or metal studs.

- Tightly docile all the elements and fasten with stiletts, after which it is possible to shoot the bottom.

- Put the bottom, leaving a small stock.

- Remove the chamfer to the straight line and knock down the hoop, weakening the fastening of rivets.

- Insert the bottom into the User and turn the bottom of the bottom down.

- To delay the hoop.

It will remain to make a lid on a tub and, checking the construction for strength, proceed to the use of the container. If the work done fell in the soul, it makes sense to continue work on the manufacture of barrels.

Cooking moonshine and alcohol for personal use

absolutely legally!

After the cessation of the existence of the USSR, the new government stopped fighting moonshine. Criminal liability and fines have been canceled, and an article on the ban on the production of alcohol-containing products at home is seized from the Criminal Code. To this day, there is not a single law prohibiting us with you to engage in your favorite hobby - the preparation of alcohol at home. This is evidenced by the Federal Law of July 8, 1999 No. 143-FZ "On the administrative responsibility of legal entities (organizations) and individual entrepreneurs for the offenses in the field of production and turnover of ethyl alcohol, alcoholic and alcohol-containing products" (Meeting of the Legislation Russian Federation, 1999, N 28, Art. 3476).

Exposure from Federal Law RF:

"The action of this Federal Law does not apply to the activities of citizens (individuals), which do not produce products containing ethyl alcohol in order to sell."

Moonshine in other countries:

In Kazakhstan In accordance with the Code of RK on administrative offenses of January 30, 2001, N 155 provides the following responsibility. So, according to article 335 "Production and sale of alcoholic beverages of homemade production" illegal manufacturing for the purpose of selling mogon, chaqi, taut vodka, brags and other alcoholic beverages, and equal to the sale of these alcoholic beverages entails a fine of thirty-monthly calculated indicators with confiscation of alcoholic beverages , apparatuses, raw materials and equipment for their manufacture, as well as money and other values \u200b\u200bobtained from their implementation. However, the law does not prohibit the preparation of alcohol for personal purposes.

In Ukraine and Belarus things are different. Articles No. 176 and No. 177 of the Code of Ukraine on administrative offenses are provided for imposing fines in the amount of from three to ten non-taxable minimum wages for the manufacture and storage of moonshine without the goal of sales, for storage without the purpose of the distribution of devices * for its development.

Practically the word for word repeats this information. Article 12.43. "Production or acquisition of strong alcoholic beverages (moonshine), semi-finished products for their manufacture (Braga), storage of apparatus for their manufacture" in the Code of the Republic of Belarus on administrative offenses. Clause number 1 reports: "Production of strong alcoholic beverages (moonshine), semi-finished products for their manufacture (Braga), and the storage of devices * used for their manufacture - entail a warning or imposition of a fine in the amount of up to five basic quantities with confiscation of the specified Drinks, semi-finished products and devices. "

* Create moonshine apparatus for home use is still possible, since the second appointment is to distillation of water and receiving components for natural cosmetics and perfumery.

Oak barrel - a great deal for a person. It can be shed vegetables, make wine, moonshine, brandy. At worst, it's easy to sit until squeezed as some, a great idea. No wonder in the old days the manufacture of barrels was the lot of real masters. We continue to tell you about the development of which you can do in the country. In the queue - coordination.

Unlike many extinct professions, such as culk, lamparer or kasternyt, Bondari is quite in demand in the 21st century. Production of families, barrels and decorative bar elements are now delivered to the flow. Beer and wine tanks are manufactured in an industrial method - spacious shops, computer control Quality, wholesale deliveries. Cost, depending on the volume, ranges from several hundred to tens of thousand rubles.

But, of course, the Russian man's craving for things made own hands, not to win. Therefore, if you have decided to make a barrel of your dreams yourself, we can only press you ... Consider! Follow the recommendations below the recommendations - and any Diogen will tell you thanks!

So, where does the barrel begin?

Select tree

Of course, you first need oak. Moreover, not the first one, but more or less adult, with a barrel diameter of 40-60 cm. Some instances can be rejected at the inspection phase. Thus, the characteristic tubers on the trunk testify to the defeat of the giant tobacco rot.

Also, "sifoving" twisted and knocked trees. In the celestial, only "tulka" is used - the first 4 meters of trunk, the rest can be safely turning the fuel for the mantal. Yes, if the tree you like it does not work, it can always be bought, on the nearest pailoram.

Making rivets

Now a little theory. Barrel consists of wooden details, rivets, tightly fitted to each other and raised metal hoops. And on how accurately the technology of manufacturing these elements was observed, the final quality of the entire product directly depends on.

First of all, decide on the dimensions of the future barrel. Its height will affect the length of the riveting itself (it must be more than 2.5-3 cm).

Chose size? Scroll through it prepared earlier oak rounder. Well, when the farm has a hydraulic column. Well, if not, the oak is fully splitting on the sector by the Dedovsky method, with the help of wedges. As a result, there should be 8 radially sloping offs.

Now cutting the core and soft "white" fabric on circular saw. From the resulting billets, we choke even the equal bins on the reysmaus.

Ready? And now ... fold all this beauty with stacks somewhere under the canopy. And leave at least a few months. And it is better for a year - a good oak barrel for an hour is not mastered. During this time, the sun and the wind, without creating the wood of unnecessary stresses, remove excess moisture from it. You can still do the grapes (for the Moscow region, by the way, there are excellent varieties, tell me somehow anything). When the blanks are dried, you can continue. With the help of an electric bike, give the boards the correct cigar-like shape, where the thickening will be wider than the ends of just 0.8-1 cm.

The inner facet of blanks is shredding in the middle curved row. Stop less than a millimeter, and when it is necessary, the riveting will be bent in the right place. The outer face is attached to the form of an arc, the curvature of which is determined by the special pattern. Its radius depends on the radius of the produced barrel. The tool is easy to make yourself. As a result, the product should turn out the same as in the figure.

On average, the barrel will need from 25 to 30 rivets.

Production of hoop

When the rivets are harvested, you can go and hoops. You will need an unintelligine strip of 2-3 millimeter iron, a little more than the circumference of the island.

Twist it into the ring and fix rivets at the ends. The hoop is almost ready. Slightly dismissed the inner side with a hammer - and you can wear on the core. For a small barrel, two pairs of wrap will be needed. Not less! Suddenly some ring will not withstand the fermentation of your beer?

While you work with hardware, make a couple more metal brackets. They will serve as "clothespins".

Build barrel

Rovers are harvested, hoops are ready. It's time to assemble it all in a pushed barrel. Take the finished ring and in arbitrary places, secure the knitters of two to three rivets in it. The design will resemble a stool. In this position, fill with rivets the entire perimeter of the hoop. When the last doorway becomes in place, we will set the metal belt with a hammer to fit the details densely.

But before dressing the second hoop, the tree will have to heat and disappear. This is done so. We endure our semi-finished product on fresh air and install it "socket" up. Inside the small metallic urn filled with chip is placed. In it ignite the "bonfire". While the fire burns, wet the tree with water. It will keep it from fire and add flexibility boards. After half an hour of such a "bath", sketch the ends for free from the hoop, and pull the quiet winch. At this place a hurry is unacceptable. The path to the finish line can take from 40 minutes to 3-4 hours, but any burst of a riveting will immediately return you to the beginning of the distance.

As soon as the wooden fan climbs, immediately scroll the hoop. Just do not forget the old Bondar law: "One place twice the hammer is not knocking." Simple words, hazing the hoop, apply only one point for each place. In no case do not beat there two or three times - split the tree.

When metal widges have become in place, the barrels are traced. The inner cavity is leveled with a special scraper and polished with sandpaper.

And now another test of fire. So that the tree is accustomed to its new form, it needs to be burned. Scheme the same - chip burning in the urn. Fire is constantly stirring, otherwise the barrel will light up. There are no ready-made recipes. We will wait for the board - the wine will take the smell of Gary. Finish the firing ahead of time, and the riveting will break the hoop.

Production and installation of bottoms

At a distance of up to 2.5 cm from the ends, select the so-called helical groove. The bottom will then be inserted into it. Previously, such an operation was trusted only by a special cutter, to a spruce (another dying profession!). Today it is much easier to use the cutter. At the same time, you remove the chamfer from the ends of the barrels. It will be useful when shrinking DonEv.

For their manufacture you will need rivets again, only a little large sizes. They are connected to the shields with steel nails without hats. Measuring on the length of the length of the aperture groove, you can easily determine the radius of the bottom. Out it on the shield and drink the electric bike. Shoot the ends sharpening.

The connection of the bottom with the core looks like this.

To plant the bottom in its place, the core will have to get the core on one side. Rivets by this time must be kept form. Will Krejangush in a helical groove, suck in the place of China - and again pull the product to the hoop. If everything is done correctly, the bottom will not penetrate. Before repeating the operation with another bottom, cut the drain hole in it. Diameter - 32 mm. When everything is ready, grind the barrel, giving it a commodity look, and cook for soaking.

Soak

In principle, the barrel is already ready. You can calm down on it, but the tree is still too saturated with tannins and tanning substances. Therefore, they will have to soak them, otherwise the contents of the barrel will deteriorate.

Fill the package by a third of hot (80 ° C) with water. For half an hour, rotate the barrel so that the moisture moves throughout the perimeter. Further drain the liquid, replace it on the cold. It should stand in the capacity of the day, after which it is replaced again. And so - for two weeks. Someone puts out a barrel ready for wine, someone's moonshine. Everyone has their own style. But it is still worth starting with water.

Now the keg is really ready under wine. Or beer. Or moonshine with cucumbers - what do you choose? ..