Doors for fireplaces do it yourself. How to make heat-resistant glass with your own hands? Fireplace doors with glass with their own hands

It would seem that the fireplace doors the thing is not the main thing in the arrangement of the focus, but this is not right. By no means important as they will look on the background general design Heating construction.

Advantages of fireplaces with closed firebox

Let's refer to what special doors are installed in the fireplace? Of course, traditionally, this focus was installed without any closing devices, but over time heating construction Improved and began to be complemented by the doors performing several functions.The most significant in this case is the prevention of premises from dangerous in terms of fire sparks and smoke products of combustion (soot and soot). In addition, the presence of the door creates a guarantee of a more reasonable consumption of firewood, and the residual coals in the closed fireplace fireplaces be burned more fully. Based on this, the closed focus creates a greater amount of heat at exactly the same fuel consumption as open foci.

If necessary, you can transform a fireplace into an additional place of heating of the room. For this, the house performs forced convection, or connect to the hearth tank, which, in turn, will be connected to radiators. Immediately, let's say that he is hardly able to heat large areas at the expense of such a device, but in the country house the fireplace will be just to the place.

Features of the fireplace door

There are some features that should be considered when choosing fireplace doors:- - The air must freely enter the device furnace. The door should be used as the subject of regulation of thrust and full fuel combustion,

- - An important task of any fireplace door is the security feature. That is, they should not influence the emergence of a fire in the house,

- - Materials for the manufacture of doors should be characterized by increased heat resistance.

.jpg)

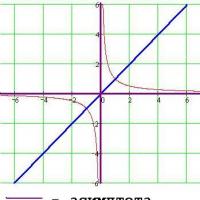

Glass structures

The most famous is the option of glass doors, since this device performs two functions: decorative and protective. Since the glass is transparent, an overview of living fire will be opened through it. The glass for this is used special, - refractory, so the fire with this contact will not arise.To perform such a device, glass is used, which includes quartz or crystallineramic. Thus, glass doors have high refractory and protection. Due to them, it turns out to support the combustion procedure in optimal mode and ensure full-fledged oxygen access to the fuel combustion zone.

Fireplace glass is available on sale

- flat (one glass);

- segment (three glasses);

- Circular (for central fireplaces).

As a rule, an increase in temperature in the house is considered an additional feature of the fireplace. Today there are a lot of more efficient heating options. But in the sense of decorating this hearth there is no equal. Thus, the glass door for the fuel cell is considered an excellent opportunity to provide a full dwelling decor. The latest methods Performing heating equipment allow at a high level:

- - Fireplace doors can be laminated or tinted,

- - exist combined devices From glass and metal. The finish is used mosaic, art forging and casting,

- - special adaptationwhich helps to open the door by the type of guillotine.

Planning yourself to make the door for the fireplace with glass, keep in mind that:

- since during heating, the material can expand, then a small gap is left between the glass and the metal frame;

- very carefully you need to take the installation of the door. So first install the frame, and only after that the glass itself is inserted. Since the glass firebox glass is fixed on special bolts, it will be completely easy to get it;

- the gaps between the frame and glass are stacked by a fiberglass layer.

Forged and cast doors

The execution of the firewall is often carried out with casting or steel. Cast iron, as the material, is used when casting, and steel - with forging. This is an intermediate version between glass and deaf elements. A similar subject is most often used to decorate the hearth than as the main functional. After it is ready, it is treated with a special enamel, thus it turns out to extend the life of the structure.Metal doors

Let's get closer to how metal doors can be made on their own. Such material is considered the most acceptable and price and in durability. Such devices are highlighted by the simpleness and safety of operation, they can be used for a long time.Designer solution you can pick up on the Internet, there are many photos and videos on this topic. Instructions for manufacturing doors for the fireplace will be shown below.

Fireplace doors of a similar sample differ in their positive characteristics:

- low value of the material;

- the probability of manufacture independently, which will significantly reduce the price of the device;

- metal fireplace door presents this durable and reliable device;

- it is considered a good heat accumulator, equipped with the possibility of regulating the thrust and height of the flame.

Tools and materials

List a list of tools and materials.For independent manufacture Fireplace doors you will need

- drill;

- Bulgarian;

- a hammer;

- Welding at 220 V.

- corner;

- sheet metal;

- a pen;

- catch;

- Curtains.

Making the door

Since the work is not a great difficulty, you can make it on your own. Note that the fireplace door must be performed in advance, even before installing the fireplace itself. Frame with refractory glass is embedded in the masonry of the fireplace during its execution.- Runs the material on a flat surface and mark the desired outlines.

- Control the accuracy of compounds using the coal.

- Fix the welding joint components.

- After welding, it is necessary to simplify the diagonal very accurately. The body you perform must have a strict geometric shape.

- Only after all measurements are performed, the remaining elements of the fire frame are welded.

- During welding on the surface of the frame, there may be influxs that are removed using a grinder and a credit circle.

- Next, the frame is laid on the metal sheet and the contour draws, for which a special hell is used.

- Provided that the thickness of the sheet is two and more than millimeters, it is not necessary for a separate frame of cooking. After you first mark the outline, you will need to draw a second outline, but already more than the first one. The metal must go to the corner, thus the volatile combustion products will not enter the room.

- With the help of a grinder and the cutting circle, a separate element is cut.

- The curtains are welded to the fireplace frame.

- Carefully examine the frame on the correct installation of curtains.

- Curtains weld to the sheet.

- We open and close the door, thus, check how the fireplace door functions.

- I liquidate welding. Fix the handle and valve.

If we summarize, the production of the frame on its own is a completely simple procedure. Make such a door can anywhere who has some construction skills. As a result, you will get a great fixture for the fireplace.

Today, more and more people who have their own country or private houses, cottages, bath buildings or just summer gazebos on the street, prefer stationary heating all sorts of portable furnaces (burzhuyki, induction or bath designs). How distinguished these heating units for the bath with their device, design or design, some details remain unchanged. For example, each stuck for the bath has doors for a filling or other compartment. Minor, at first glance, the item can very much affect the work of the entire unit.

To date, everyone is divided into several groups on the basis of what material the details are made:

- To the first type belongs all the chims cast iron elements. Cast iron furnaces for fiber devices are not very popular in our time due to the fact that they are very capacious, severe and inconvenient to use. Their installation also delivers many problems.

- In the second group includes chimneys iron And some cast iron doors. As a rule, stainless steel is in the role of the main material, and coarse devices are used with iron doors, mainly in the baths or for other purposes, in which the furnace directly contact with water. In the furnace cast iron units for the house, iron doors practically do not apply, by virtue of their technical characteristics.

- The third type includes all furnace doors, where as the main or secondary material protrudes panoramic glass. Details from this material today are much more common than cast-iron or steel elements (or other metal) for flue devices.

In this article we will look at exactly panoramic glass doors: We describe their bad and good sides, listing areas of use of flue devices with glass doors, tell about the varieties of this type of elements.

Advantages and disadvantages of glass doors

- The first positive quality of chimney for heating units from panoramic glass is their (high-temperature resistance), which cannot be said about cast iron elements. This quality is very important, because if items are not heat-resistant, the heating or heating device will not work normally. Glass due to its specific chemical propertiesUsually, withstands very large temperatures in contrast to stainless steel.

- It should be noted that the second plus of stoves with glass furnace doors is their fireproofWhat can also be said about cast-iron doors. It is also very important, since the furnace doors often in contact with open fire during the operation of the heating device.

- It is impossible not to notice that everyone wants to give a little comfort to the interior in his house or gazebo. And the type of flame and burning firewood will do it as it is impossible. The furnaces made of glass are transparent, and when you want to protrude the stove for a bath, a pleasant bonus will become beautiful view Live fire.

- Another positive feature is that the doors data fully safe When operating a stove for a bath. Details are made of special glass, which includes transparent crystal ceramics and heat-resistant quartz. This composition provides complete absence of explosion hazard and the possibility of fire.

- Lightness I. small sizes Glass elements also play a significant role when installing parts and their use.

Despite the abundance of pluses of glass doors for a bath or dacha stovesNegative parties also have:

- The first minus is fragility material. This means that the installation of parts should be made with maximum caution and care. Also, when you install the elements in the baths for the bath, it is not recommended to clapping them when using the aggregate.

- The second minus is fast Panoramic glass pollution. A large number of people using stoves with glass doors came across this problem. The material is quickly covered with mud, soot, and most of all - soot. You will have to spend a lot of time cleaning surfaces, eliminate dirty coatings.

See also: How to drown the oven

As you can see, negative sides are much less than positive, it is precisely thanks to this indicator that the glass doors for furnaces are so patched.

How to Install the Glass Door

Before the direct installation of the door for a bath for a bath must be checked how easy it can be discovered. If the item is a tight, it is poorly discovered, its it is necessary to develop.

In Russia, the asbestos gasket is used extremely rare in the stoves for the bath. To date, Asbestos is borrowed from industrial furnaces (not for a bath). In this type of stove, the asbestos are necessary because industrial heating units are faced with very high temperatures.

As a rule, in ordinary room heating structures, the temperature is not so high, and the door frame is never openly in contact with the flame, therefore the expansion of standard stoves is completely insignificant. Even despite the fact that some piece iron Wirewhich is located near the door, is naked, the door itself is quite tight and firmly. Some experienced burns drill a few holes in the door frame, it is done near her edge (for a greater warranty). Nowadays, there are many different ways to fix the coarse doors for the bath.

The best and proven method that allows you to avoid the false door dropping: when mounting the heat door you need to stick to it metal plates (Their thickness should be 2-3 mm.) From the upper and lower sides. It is recommended to choose metal plates with special advanced ends. After all the actions done, you need to sue them in a brick.

You should also pay attention to the fact that before installing the furnace door, you must attach under it grid grate. Then you need to attach special plates and wires to the door and put it on the solution. The next action will be the dilution of the plates or the ends of the iron wire on the inner walls of the flue compartment of the heating unit. After that, it is necessary to put other ends for two bricks and press them from above one or two bricks.

The angle of the installed door is recommended to be checked using a plumb. As the last tool, you can use the softened iron (preferably steel) wire, which previously passed firing in the furnace. The iron wire diameter should be approximately 3 mm., And length is 110 cm. After you inserted the latter in the hole of the door frame, you need to fold the wire twice and very tightly twist (the rings should not be). In the event that you performed the work of poorly, and the rings were still formed (especially in the door area) you need to hit them with a hammer. Punch is made along the entire length of the wire.

Fireplace doors made of glass are beneficial and harmonized with any interior of the room. A fireplace with an open furnace, of course, allows the flame to look more fascinating, but such a variation is unsafe, especially if there are animals or small children in the house. Sparks that can fly from the focus firebox can lead to burning or receiving burns!

Also, open focus can be a consequence of the smoke of the room, the incorrect burning of oxygen.

In order to increase the level of security in a room with a fireplace, it is recommended to install a door with glass!

Need element or secondary?

You can buy the doors with glass for your fireplace in a specialized online store, as well as make this item to order. After installation, you can solve problems associated with smoke, danger of fire or burns.

The main thing that the model you chose has provided the necessary degree of security, was distinguished by reliability, harmonized and combined with the style and design chosen to install the room. Equally important and simple use, tightness.

In assortment you can meet various variations And the models of the door for fireplaces, among which there are metal, glass, combined models made of refractory hardened transparent glass.

Deaf metal, cast-iron and steel fireplace flaps look more solid than and visually different from glass. You should not give preference by cast deaf doors, if you want to observe the combustion process in the fireplace of the flame.

Doors with glass for fireplace - this perfect optionwhich fully retains the visibility of the flame. The benefits of this variation include the possibility of not only to monitor the burning flame burning in the furnace, but also to monitor its level and intensity of burning.

Fireplace doors do not allow smoke in the room at home, decay products, ISPORS, which increases the level of safety of using such a heating unit to a maximum.

The closed firebox provides a higher efficiency, produces rational combustion of oxygen, does not allow to form an excessive amount of soot, the raid. The focus, closed with sash, also creates the necessary noise insulation, so that the crackling of the extinguishes will be pleasant and unobtrusive. The benefits of this option include its efficiency and average fuel consumption (lanes, briquettes, biofuels, coal).

What are the requirements for materials

Fireplace doors are made of materials such as: high-strength and heat-resistant glass that moves high temperatures well, their sharp differences and strong heating. The temperature of the order of 9500 may be maintained by a practically unlimited amount of time, which is why the sacker of the closed focus is not regularly prohibited!

The main components that are part of the heat-resistant glass is a heat-resistant quartz and transparent crystal ceramics. Quartz glass enjoys the greatest popularity, even with a strong heating, it does not significantly expand and thereby can be perfectly combined with any other finishing and construction materials.

IMPORTANT: Thermal station is strictly forbidden to use for the assembly and configuration of the fireplace doors! It cannot withstand temperatures exceeding 1400 degrees. As a result of strong heating, it will simply crack, unlike heat-resistant, which is comparable to metal according to its characteristics.

Depending on the selected variation, style of execution, model, thermal station may have various shapes, design, execution, design, degree of bulge and bent.

Toned glass is one of the variations that is allowed to be used to make the fireplace door with their own hands. The color of the glass may be different, which in turn makes the flame in the focus blurred, fuzzy, gives him a different shade.

The most reliable and safe are such varieties as: multi-layered and double glasses for the fireplace.

Criteria that need to be considered when buying glasses:

- The heat resistance of the element should be at the highest level. The product should be well transferred strong heating, sharp drops temperature mode;

- The service life of the goods must be essential (more than 15 years);

- The optimal thickness of the glass screen will vary from 3 to 4 millimeters.

The main drawback of refractory glass is a big weight, which creates the need to buy and choose massive, maximum reliable loops, fasteners and other fittings.

Possible design door

Fireplace doors can be automatic or mechanical. Mechanical flaps are able to open manually, this option belongs to the category of classic, most simple and budget. The automatic fireplace doors are open using the underlying the design of the electric motor.

Since the risk of getting a burn Even when opening the sash is large enough, it is recommended to set a safer automatic option.

Glass doors are closed with one of several ways. They can be both lifting and sliding. Double swing doors enjoy more popular and demand. Both halves converge together in the central part of the hearth and amplified by side loops. The features of the swollen variation include the fastening of one sash side loops, the door is equipped with a mechanism that allows you to close the hearth up.

It is interesting to know: to modern design solutions There is a variation that allows the opening and closing of the focus on the principle of guillotine. In this case, at your discretion, the furnace can work both with an open and closed flood chamber.

In order for the fireplace doors to converge, it is allowed to use special magnets. Magnetic doors are very safe, they provide full closure and opening doors, depending on the need.

Pay attention to the type of fasteners than their more and what they are massive, the more expensive you will be installed and buying this item.

The fire door is fixed on the loop and around the perimeter is equipped with a steel or cast-iron frame. For the handles, any stainless material is selected. Optionally, you can choose a steel or pig-iron base for your hearth. However, it is precisely steel doors for more durable, and while the cast-iron is much faster losing their strength and wear out.

When buying a glass door for the stove, pay attention not only to its operational and specifications, but also a designer, styling component. The frame can be equipped with a metal framing or have decorative wrought elements, various decor, ornament, stained glass windows.

Care and installation

Glass fireplace doors and care for them is carried out according to the following recommendations:

- Cleaning is carried out only after the heating unit has completely cooled after the extracts;

- Need to buy special cleaning products that will be reliable protection, I will form a special coating, the film on the surface of the sash.

An excellent option making cleaning and care is the most simple as possible - it is to buy self-cleaning refractory glass. It is covered by metal oxide, in the process of heating, which contributes to the fact that the sedentary soot is completely roasted.

In order to choose the fireplace doors, you will need to make a purchase before the completion of masonry work. This will allow you to make the firing in the most suitable size.

Buying and installing fireplaces together with all the necessary accessories, elements and components, allows you to recreate a unique one harmonious design living room, dining room, bedrooms in the house, apartment or in the country.

Certified glass doors fully comply with all safety rules, so you are guaranteed high quality.

Making your own hands

Not many know that we can make fireplace glass doors with your own hands at home. For this there is no need to have defined skills. All that is needed to perform such works is the presence of a special tool that will allow you to work with glass and metal, as well as a welding machine.

At the first stage you will need to do detailed drawingAccording to which you can define the form, size, style execution and other important parameters of this item. After that, it is necessary to make calculation and buy materials, fittings and components for the assembly of the fireplace doors.

As a basis or otherwise, the frames, we use a steel or cast iron frame, which is collected from a certain number of sidewalls, each of which is connected by welding. The center of the frame is installed glass, selected and pre-veneered in size. It will also be well fixed!

The glass is chosen only a refractory, hardened, which is well tolerated strong heating. Since work with glass is very complicated and painstaking, determining the necessary size, you can give it to the workshop. It will cost inexpensively and you will receive a guaranteed positive result!

Next, we produce the fixing of the handle, it is important that it is convenient and also has been made of refractory materials, stainless steel. At the last stage, it is necessary to secure the glass door to the fireplace itself. This is done with the help of special loops and fasteners. It is important that they can well withstand the weight of the flaps, possessed refractory properties.

Thus, now you can decide for yourself, it is better to buy the doors with a glass for the fireplace or make your own hands from the house. In any case, remember that hermetically closed firebox is a guarantee of safe use, protection against accidental ignition, getting coal and sparks to the room.

In this video, you can learn more about how do the doors with glass do it yourself:

The furnace doors are widespread and manufactured from the most different materials: cast iron, metal, panoramic glass. They are found on the furnace holes of all stoves and fireplaces.

Opening the door can be added firewood, Regulate temperature, and through the glass is observed for the burning of the lamps.

Choir doors with glass

Glass doors for fireplace or stoves are the following types:

- circular;

- segmental;

- flat (thickness in one glass).

Doors for furnaces and fireplaces, where glass is the main or secondary material, are especially widespread.

This is due to a number of qualities:

- fire resistance;

- safety;

- easy;

- aesthetics.

Advantages and disadvantages

A panoramic glass of good quality allows you to see what is happening inside the furnace and does not get out. Such a door absolutely safe. Stan refractory. Unlike the same stainless steel, panoramic glass not deformed from high temperatures. Many homeowners cast iron or iron elements in the interior seem rude. This can not be said about panoramic glass, which harmonies with any finish.

Of course, such a door has and minuses. The first one is fragility. If you are inappropriate to hurt the noche stainless steel door, it will not affect it, but the glass will crumble. In addition, after each extract cleaning from sootOtherwise, the glass quickly ceases to be aesthetic and transparent, acquires a sloppy view.

Photo 1. The "HG" cleaner for heat-resistant glass, 500 ml, is suitable for removing the soot and soot from the glass door.

Heat resistant glass capricious, for cleaning it no detergents with abrasive compositionSince it will easily damage the polished surface of the screen.

Metal doors

Metal doors are widespread due cheap, lightness of installation, convenience and fire resistance. At the same time, they provide absolute tightness of the design. If the door is made poorly and passes oxygen, it will sooner or later lead to a fire. Therefore, the burning, mounting the coarse flaps, constantly checks Level of tightness. Only this gives a guarantee of quality work.

Rigs from cast iron

Cast iron targets are used primarily in furnaces, such as , baths, And not in fireplaces. Their indisputable advantages High Fire Resistance, Immunity to Turning Difference.

But such gambles will not pay those who love to watch the dance of sparks and burning firewood. Looks like cast iron not aesthetically, uncomfortable in work, heavily serves lessthan metal constructions.

Making a glass door for a furnace with her own hands

As the basis for machine door with glass use metal(more often stainless steel or cast iron). According to the reviews of experienced cooks, cast iron is preferable: It is durable, not afraid of high temperatures, it is well cleaned, it is distinguished by strength. Stainless steel With the furnace stove he is strongly lateis not adapted to withstand open fire and quickly breeds.

Tools and materials

To work, you will need:

- bulgarian;

- metal sheet;

- heat resistant glass;

- construction gloves;

- masonry composition;

- welding machine;

- level;

- fiberglass.

Choosing panoramic glass, you need to remember its fire resistance.

Stages of work

Work on the installation of the door consists of the following steps:

- performance drawingall the design;

- cutting blanksfrom metal for framing and sash;

- manufacture framework;

- fittingframes on the glass;

- bait of canopies;

- weldingframe parts, installation of a glass element;

- installationcanopies, valves and handles.

Attention! The challenge forces to those who have at least initial experience in working with welding apparatus . If you did not do before the welding, you recapture this task to a professional.

You will also be interested:

Creating a billet

First measure the magnitude of the fireplace. On the set parameters cut the corner

Frame has on a metal sheet Placed circuit. After checking all measurements, the workpiece cut with a grinder or cutting circle. It will be a pendant for the door.

Glass element attachedthrough the bolts screwed into the corner along the plane. They will not give the window falling, but do not interfere with thermal expansion.

Door must attack Through. sheds.

Attention! Before mounting a glass insertion remove from the frame!

Corner door checked with a plumb. For this use three-minute-moving wire, pre-buried and softened on fire. It is inserted into the hole of the frame, folded twice and tightly twisted, so that the rings are not formed at the ends. If without them it did not cost, the wire is broken with a hammer.

Fully deaf stem, without window, meets less often. It is made according to the same principle, but without a transparent element. When the frame is ready, mark and cut out the future sash, following it to lay on the hole vansel.

Fastening to the base

Frame with the door just do not attack the brick. Would need special niche. First, the contours on the masonry are placed, then the diamond circle is peeling.

Most often for fastening use anchors made of metal. Before mounting the door to the base, check whether it opens easily. If it succeeds with visible effort, the workpiece must be finalized.

Rama Podloki is wound asbestos cord, then failed with heat-resistant glue. The cord will have to push into the recess around the perimeter of scolding.

Doors for furnaces and fireplaces can be made from many materials, although it is mainly a heat-resistant glass or metal. Special responsibility should be taken precisely when choosing the door; There is nothing surprising in this, any door is the facial element of the heating device, which affects not only the correct functioning of the equipment, but also on its aesthetic characteristics. Today we will discuss what this constructive element represents what it can be, which functions perform; A brief comparative overview of the most popular models and their average market value will also be given.

Stock Foto Door for furnaces

Comparative characteristics and prices

The table below shows the popular models of fireplace doors, their characteristics, as well as the average market value.

DK 555-1k. "Ruslanovo-masonry" 53x55.4 cm Steel, heat-resistant glass From 10,000 to 11000 rubles |

|

|

|

|

|

|

|

|

|

|

As you can see, even among popular models there are representatives of different price ranges. But for the quality, as you know, you always have to pay more.

Characteristics and selection of refractory glass for fireplace

Earlier, we talked in detail about what you should pay attention to when choosing refractory glass for the fireplace, we considered their properties and specifications, in addition to this article we advise you to get acquainted with this information.

What should be such doors?

There are certain requirements for furnace doors. Read them.

- In the manufacture of doors, exceptionally those materials that are characterized by increased fire resistance should be used.

- Also, they should not prevent the oxygen penetration into the fiber chamber. The optimal option will be the possibility of adjusting the air supply, which will affect both quality and the amount of fire burns.

- Finally, the doors must be fireproof so that the room is reliably protected from fire.

Video - Fireplace doors

Varieties of fireplace doors by type of material

Depending on which material is used in the manufacture, data constructive elements There may be several types.

Heat-resistant glasses

Immediately disclaim that this design option is becoming increasingly popular, and the reason for this is quite obvious: when fuel burns, the user will have the possibility of visual observation of flames. Glass doors differ from others - made of metal - what possess their own, special style. For their manufacture, a heat-resistant glass is used, consisting of many elements, including from heat-resistant quartz and transparent crystal ceramics. Thanks to this, products take place not only aesthetically attractive appearance, but also an increased level of security during use. Glass doors are produced immediately in three varieties:

- in a flat (characterized presence of thickening into one glass);

- in segment (in three glasses);

- in circular (the use of such models is more expedient in the fireplaces located separately).

Note! Often, glass products are combined with metal (we will tell about them in the next paragraph of the article). In such cases, the door frame is made of steel, and she - the door itself - from the glass.

Often the doors for furnaces and fireplaces are equipped with additional decorative elements - casting or forging, lamination, tinting, finishing with a mosaic or stained glass window. Moreover, there are even lifting or sliding options such doors.

One of the few disadvantages of products from heat-resistant glass is the fact that soon after the start of operation, their surface is covered with soak, and they are generally contaminated fairly quickly. Although there is a solution to this problem: it is necessary to further take care of the cooker's roasting system (even at the fire / furnace / furnace stage), so that it (soot) will be burned during the operation of the heating device.

Doors from iron

This category includes such doors that are fully made are completely made of metal. The procedure for their installation is extremely simple and does not have anything difficult, the products perfectly hold the thermal energy and, most importantly, differ in the increased degree of fire safety. Yes, and in terms of reliability and functionality, iron doors - most optimal option. If there is a desire, then they can be made with their own hands with minimal cost (more detailed about it - at the end of this post), although the "factory" model can be bought in the store at a more than an affordable price.

So, here are the main advantages of metal structures.

- The main advantage already mentioned above is available. If we compare it with the cost of glass doors, then it is several times lower, which makes a certain popularity, the advantage in the baths and dachas, where the functionality is known, on the priority scale is much higher than the aesthetics.

- In addition, such doors are durable and durable. And if they care about them (the departure itself is only in periodic anti-corrosion treatment with the use of paints related to the category of heat-resistant), then they will serve many decades, without delivering users completely no inconvenience.

Note! Despite the fact that the iron doors have their own buyer, the market demand for them is quite low, as they do not allow visually to observe the playing flame.

Doors from cast iron

Just like the previous version, such doors are used primarily for furnaces in the baths and in dachas, but they almost do not occur in fireplaces. In general, this is a kind of intermediate link between iron and glass doors. Their use is explained by increased resistance to elevated temperatures, but in this case, of course, the service life is damaged (if compared with the metal) and the aesthetic indicators (with heat-resistant glass). Although if you wish, you can make doors for furnaces and fireplaces more aesthetic, if we cover their fire-resistant enamel.

What should pay attention to when buying? General recommendations

- If you wish to visually watch the fire, then you will need either a fully glass door, or metal, but with the inserts of their heat-resistant glass. At the same time, the higher the cost of the product, the greater the aesthetic appeal.

- If the thickness of the fire-resistant glass is less than 0.4 centimeters, it is installed in the damper using the seal and with a slight gap, which is necessary in order to compensate for the thermal expansion under the action of the flame (otherwise the material can burst).

- In order to protect children or pets from burns with random touch to a hot surface metal doors It is recommended to install with a special shield, due to which its surface will not be heated above 40 degrees.

- If the heating device functions on mixed fuel, consumes coal or coke, the door must necessarily be made of cast iron. If firewood will be used as fuel, then the glass product can be installed.

- As for the sizes, the selection is recommended to entrust the experienced focus, which will build the heating device at your home. Indeed, in this matter it is necessary to take into account a number of important nuances, which is not given to a person in fairness.

Note! Do not forget that any fireplace or oven is, first of all, a potentially fireproof device. For this reason, the construction process must be approached with the corresponding knowledge of the case.

We also note that preference is desirable to give two-sided structures. In such designs, external flaps (they are solid) are equipped with a slit, by means of which the flow of the supplied air required for burning fuel is adjusted (the moment is especially important for devices on firewood, which are not equipped with ash spots). And the inner sash (they, as a rule, lattice) capture coals and sparks, preventing them from penetration to the second sash. This minimizes the risk of fire.

Doors may differ not only by number of sash or type of material used, but also by external execution. Thus, products from the company "Thermophore" are produced in classical black performance, and in brilliant (from the "stainless steel"). Some models are equipped with special inserts under fire-resistant glass. In others, it is possible to connect the air intake nozzle from home or ensure full tightness floor chamberThanks to which you can adjust the automatic control system and adjust the functioning of the heating device.

Note! The dampers are often equipped with special sensors that notify the user about each opening and heat heating temperature. Separate models (such as Hoxster) provide manual air supply regulation.

Heat resistant glass

So, we found out that in most cases consumers prefer to install the doors of the fireplaces and furnaces, performed by their heat-resistant glass (the exceptions are those devices that are consumed by coal or mixed fuel). What lies the secret of popularity? First of all, the fact that today the production of such glasses has noticeably improved and complicated. Manufacturing process Consists of several stages, such as:

- heat treatment;

- processing of chemicals;

- polishing at high temperature.

With the help of special glass furnace furnaces, manufacturers produce sheets of material of the required thickness, and their surfaces are processed by special preparations that increase not only fire resistance and strength, but also the operational life of finished products.

Note! Thanks to a special polishing, any cracks or chips on the glass are missing, it turns out absolutely transparent and perfectly smooth.

After the end of all technological stages, the finished fireplace glass acquires a lot of unique positive qualities, among which:

- resistance to high temperatures;

- low warming speed;

- aesthetic and, if you can put it, noble appearance;

- excellent noise absorption;

- the ability to withstand significant temperature differences due to the low thermal expansion;

- in addition, any visible defects do not appear on the glass surface, even the most minor cracks.

Moreover, today, in contrast to several years ago, heat-resistant glasses are produced with crystal and corrugated surfaces, as well as tinted (in the latter case, bright flashes are somewhat muted).

Above, we have already mentioned the glasses that can independently remove the soot that appears on the surface. Such glasses are called self-cleaning and differ in that they are covered with a practically imperceptible ball of metal oxide. Thereby inner surface Glasses when burning fuel heated to more high temperatures, and soot, as a result, almost completely burns out.

How to care for fire doors?

We have already noted that metal doors for furnaces and fireplaces do not need special care - you just need to paint with heat-resistant paint. With glass models, everything is somewhat more complicated. For example, even self-cleaning models must be periodically cleaned from accumulated soot. For this procedure, a wet rag and detergent (The same "Mr. Muskul"), but without abrasive components and chlorine. So you do not damage the glass and the protective layer.

Note! Remove soot only from the cooled material, otherwise it can come to unsuitability.

What affects the cleaning frequency? First of all, this type of wood used (how many resins they contain) and the force of thrust.

Making your own hands

If you plan to manufacture the door for furnaces or fireplaces with your own hands, then you first remove the size and make a preliminary drawing. After that, prepare everything you need:

- welding with electrodes;

- plumbing tools;

- bulgarian.

As for the materials, it will take a sheet of metal to create the most simple design itself, two wire sections with a diameter of 1.2 centimeters, as well as several bolts and nuts. Before work, all elements are covered with heat-resistant paint. The manufacturing process itself is presented in the video below.

Video - Production of the fireplace door

After making or shopping, the door should be installed. This is schematically shown in the image below.

In more detail with the process, you will read this video.

Video - installation of the fireplace door from cast iron