All subtleties of working with plasterboard. Secrets and nuances. Prices for plasterboard and sheet materials

What problems may occur when finishing plasterboard sheets? How can they fix them? What do you need to do when peeling the wrapper or breakdown of the design? What measures to do to eliminate the defects of the GLK finishing defects? How to bend plasterboard sheets? We will tell about this in our article.

After the finish finishing works on plasterboard, there may be problems that were not previously known about, or the technology was violated or negligence. In this article, we will consider not the reasons for the appearance and elimination of cracks in the GLC, and other frequent cases of the manifestation of defects and the methods of their correction.

Problem 1. Splitting peeling

This phenomenon most often occurs in the premises where the repair is performed phenomenally quickly and cheap. This defect may occur for many reasons.

Cause 1. Application of spatlets on raw leaf

At this moment, the cardboard gluits with a fresh twin, at the same time his bunch with a filling of the leaf weakens. The leaf can be settled with prolonged irregular storage, as well as primer (if you do not dry).

Note. It is not necessary to apply primer to the putty - it loosens the bunch of cardboard with a layer of plaster.

How to fix? Believe the spatula for detachable areas and re-slip.

Cause 2. Using seed or wheel

Sometimes to fresh high-quality (dry) mixtures add old, which lost its properties. This rough course of unscrupulous performers may be allowed in the absence of the Customer, which is entirely on their conscience.

How to fix? See the reason 1.

Cause 3. Oil stains on plasterboard sheets

Puttlevka can last up to 30 days due to its own bundle, and then peeling. The stains of petroleum products are not so ground, these sites are subject to defect and removal.

How to fix? Clean the places of spots to pure plaster. If the spot area is significant, replace the damaged area.

Cause 4. High humidity of the base or sinus between the GKL and the wall

Accompanied by the appearance of browned divorces. In this case, most likely, the leaf of GLK flows through.

How to fix? Install and eliminate the source of dampness, dry and treat antifungal compositions. The damaged section of the sheet is replaced (I do not need to change the frame).

Problem 2. After setting the lighting devices, the defects of spitels and coloring were visible.

This problem occurs in the absence of skill at the artist. In most cases, defects will manifest, if you simply paint the wipe plasterboard, without sticking the wallpaper. This cheap and fast method is visually good during repairs - everything looks smoothly and smooth. But when installing lamps, the light drops differently, and often bumps and pits are thrown into the eyes, invisible before.

Council. To see the defects in advance, bring the lamp to the plane and look parallel to the light - the smallest tubercles will be shared. Lighting should be turned off.

Methods to eliminate this effect are several.

Method 1. Shading

If the materials are used expensive or alteration is impossible, defects can be "hide" into the shadow. To do this, pick a lamp, which is 50-100 mm and having a ceiling, "plate" or reflector from above. The task is to overlap light access to the plane and direct it in the opposite direction. If built-in lamps are provided, select a model in which the lamp will be as low as possible, and will not go beyond the plane.

METHOD 2. Fucking wallpaper

If quality finish spales Hypzarter does not suit you, but there is no time or effort to ideal, the wallpaper will come to the rescue. There are many of them - thick with patterns, smooth phlizelin, vinyl-based, etc. effective method Masking of defects of surfaces from GLC - coating "ripples". This is best suited for a web-"Pautinka" from fiberglass. After installing it, you can paint acrylic paint.

Method 3. Full overlap

If there are serious defects throughout the plane of the ceiling of plasterboard, you can simply stick ceiling plates from above.

Problem 3. How to hang anything on the wall or partition, lined GCL

When planning a living space, it always tastes about the use of walls to install decor, furniture, shelves, or household appliances. The stone and the tree keeps the anchor perfectly, but how is the plasterboard cope with it? The problem is the main disadvantage of plasterboard - fragility.

Method 1. Single weight items

It may be hours, small pictures, decorations. Saws is simply screwed in the right place. Weight - 0.5 kg.

Method 2. Small weight items

Small shelves, paintings and watches large sizes. For this there is a special dowel. To install it in GLC, you need to drill the hole and simply paste it there. When screwing the screw, the back of the plastic dowel is pulled up to the back side of the sheet and increases the contact area, distributing the load from the screw along the plane. Weight - 2 kg.

Method 3. Items and Middle Weight Things

Bookshelves, hangers, small appliances. In this case, you may need a more powerful anchor with a plastic dowel. The hole is drilled in GLC and undergoes into the carrier wall. A dowel with an anchor is inserted there, but it is important to calculate it in advance. The shelf is better to hang a combination method - the upper points with a step of 300 mm per anchors, and the lowering dowels for the distribution of the load.

Another way is to find a frame of a frame with a magnet and consolidate the subject on them. Weight - 5 kg.

Method 4. Heavy items

Antique clock, massive decor elements, hallways, medium household appliances. For the installation of larger and heavy items, it is reasonable to transfer their weight to the floor. To do this, we will need vertical racks from the board (pre-treated in the tone of the interior). At the top of them need to be consolidated by anchors carrier wallAnd in the middle and bottom it is enough to install the spacer dowels. Their task is just to hold the boards next to the wall. Weight - 12 kg.

Problem 4. How easy and accurately make a plasterboard arch

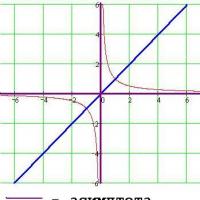

It should be noted that a sheet of plasterboard has a certain flexibility, which depends on the thickness of the sheet. For example, a 6.5 mm thickness of 6.5 mm can be bent to a radius of 1 m, a thickness of 9.5 mm - to 2 m, a thickness of 12.5 mm to 2.75 m.

Note. The radius of the right arc will be equal to half the width of the day.

It turns out that unprepared drywall is suitable for openings from 2 to 4.5 meters. We will look at the method of bending a GLC smaller radius - up to 300 mm. The rear plane of the arch is visible very well, so it should be as smooth as possible. There is an easy way to achieve smooth bending, without resorting to the transverse cutting of the sheet. It will also suit for forms with several bends.

For this, a sheet cardboard from the inside by perforifying a needle roller or just a seer. It should be done carefully so that the puncture does not reach the middle of the thickness of the plaster. Then this surface is wetted with water or primer and fix on the finished frame or template. After drying, the sheet will save the form.

Problem 5. How to seal holes, potholes, dents or revision holes in drywall

The nature of the appearance of the described defects does not interest us, only their size is important. As a repair mix, we recommend using special spatles for seams Vetonit Siloite, Sheetrock or Knauf Fugenfuller:

- Celers, holes, ripped non-separation scratches are cleaned and covered.

- Through hole up to 50 mm. At the edges we apply the maximum number (how much it will hold) putty, we gently fit the flap of the foxes 2-3 mm. The sizes of the flap must overlap the hole by 20-30 mm. We smoothen the putty to the plane with the wall.

- Through hole more than 50 mm. We clean and hang the edges. Small trimming of rails or profiles fix from the inside of the sheet through the passage of self-press, sticking with hand through the hole. Of these, it turns out a support on the reverse plane of the wall. Cut from the GLC "Plomub" in the form of a goat so that it is free to enter it. We establish a "seal" to the supports and fix the self-pressing to them. Plane spat through a painting grid.

- Break. May have a significant shape and area. First, you should evaluate the "disaster scale" (its area), removing unsuitable parts of the drywall from the frame. Then you need to inspect and try the framework - it may also require repair. After bringing the carcass in order, cut the border of the break on the axes of the nearest profiles. If the frame does not have transverse profiles, the stops described in the "seals" setting (above) should be arranged on the free boundaries (above), or install additional ribs. Then the resulting opening fill GLK, observing the usual technology. Seams are covered with a painting grid.

As you were convinced, 90% of drywall problems arise due to the fragility of the hard gypsum. However, fragility itself is at the same time the main advantage of this material. It is a weak crystal lattice that makes it easy to process, giving the most bizarre forms.

Plasterboard (GLC) is one of the most popular materials for finishing the premises. It costs it relatively inexpensively, serves quite a long time, and it is easily mounted and relatively simple. The scene surface of plasterboard sheets serves as a reliable basis for deciding with plaster, wallpaper, ceramic tiles etc. It should also be noted the carrying capacity of plasterboard structures: with competent location and fixing profiles and sheets, they are able to withstand the weight of wooden furniture or even plumbing. The main advantage of plasterboard is simplicity in processing and installation. However, that the work is performed efficiently, on time and with the smallest consumption of material, it is necessary to carefully examine its properties and choose the most convenient installation methodology.

What is GLK

The basis of plasterboard is a gypsum dough, which, depending on the purpose of the sheet material, is rejected by various components. The front and back surface of the gypsum sheet covers a special building cardboard, protected from moisture, temperature and mechanical damage. With a sufficiently high leaf stiffness of the GLCs is a fragile material, so it is recommended to work with it at least together, even if it comes to finishing small areas.

It is necessary to protect plasterboard sheets from unnecessary loads and store them in a horizontal, as a last resort in a vertical position.

Key features of working with plasterboard

Cut the plasterboard is needed from the back side, for a ruler and a very sharp knife. The effort should be sufficient, but not more - in the end, it takes only cardboard. After the segment, the sheet is laid horizontally and breaks along the line. Next you need to cut off the cardboard on the other side of the sheet. For this, the latter bends inside, and the incision is carried out from the bottom up with one even and uniform movement. If everything was done correctly, the incision will be neat and accurate.

To finish the walls, it is recommended to use GLC thickness of 12 mm, and a thinner sheet is suitable for mounted ceiling. In practice, the choice of material is carried out on the basis of the complexity and volume of the structure, as well as the presence of areas with non-standard forms and geometry. The reliability and durability of the design directly depends on how correctly the load on the frame and sheet material were calculated. On average standard plasterboard Wall With proper placement and fixation of profiles withstands the weight of about 50 kg. At the same time, it is necessary to take into account both vertical and horizontal loads on drywall - in these directions reinforcing profile are exhibited.

When working with plasterboard, one way or another will have to use the stepladder and mini-forests, as well as a different tool. All plasterboard sheet 1200x2500 m is about 30 kg, so it's not worth it alone and all the more to transfer it. And, of course, it is always necessary to remember the safety.

Nuances when installing metal profiles

If the walls and the ceiling indoors are uneven, and its useful volume is ready to donate optimal option There will be a GLK installation on the profile design. It is made of special metal profiles that are fastened with each other by the crab type bolts. When creating a design, other metal elements are used - suspensions, extension cords, clamps, fasteners, etc. Their list and quantity is determined by geometric and functional characteristics Frame installed in a particular room.

In the process of installation of the structure, it is necessary to remember that not always the corners in the premises are straight. However, the straight angle must be observed, and this leads to a complication of a frame.

To perform installation and trim design under hypospicaron, you will need:

- level level;

- tubular hydroelectory;

- roulette, pencil, notepad;

- screwdriver;

- nippers;

- tool for bending and cutting metal;

In the initial stage of installation work, markup is performed, in accordance with which the profiles under GLC will be carried out. The shelves of the sheets of plasterboard should be held in the center of the front of the guide profile. The latter is installed in increments of 40, less often 60 cm in accordance with standard width sheet material.

After markings on the length or width of the premises of the points in which the guide profiles will be installed, on the ceiling plane along the line of each of them in 40-80 cm, the suspensions are mounted. And already to them, while without a level, guides are temporarily fixed. After that, in the same way should be transverse and reinforcing profiles.

Installation of GLC on glue

Working with a design from a metal profile under plasterboard is not easy, but it is not always necessary. In some cases, it is advisable to mount HCL on special glue:

- If it is necessary to align walls or ceilings with large potholes or beatings.

- When wearing door and window slopes After installing window or door frames, as well as during the repair or reconstruction of the premises.

- When finishing geometrically complex sites, incl. With an uneven basis

The main advantage of mounting drywall for glue is reliable. On this wall, it is possible to hang pretty heavy furniture without feasures or secure various elements of the interior to it. It should also be noted that the glue fills the voids well, which ultimately has a positive effect on the sound and thermal insulation parameters of the structure. On the other hand, from the moment of gluing and to the very drying of the adhesive solution, a dense fixation is necessary, which is not always given easily.

For the preparation of glue, you will need:

- dry adhesive mixture;

- capacity for the preparation of the solution;

- drill with a mixer;

- water.

In order to save money as an adhesive mixture, a mixture of starting putty and the construction glue of PVA is often used. However, with high demands on reliability, this glue is not recommended, since the likelihood of incorrect proportions is high, which is negatively affected by the characteristics of the entire structure.

When an adhesive weight is achieved with a homogeneous, sufficiently thick consistency, it is applied to the back of the GLC, after which the sheet is installed on the position allotted for it and the force is attached. At the same time, it is necessary to observe the horizontal and vertical level, as well as the linearity, if several sheets of plasterboard are installed one by one.

In some cases, GLK can be attached directly to the main wall using conventional dowels and without the use of glue or metal frame.

Errors when working with plasterboard

In any form of construction work, the exact following technology is important. It is the latter that guarantees the quality and durability of the result of construction or repair. Unfortunately, quite often inexperienced masters when working with drywall allow serious misses, which in the end lead to the smoother consequences. What exactly should be avoided when creating plasterboard structures in the interior?

- Violation of the technology of the installation of profile design

Perhaps the most common error when installing the carcass under drywall is the discrepancy between the profiles used their intended purpose. You can not mount a DC profile instead of UW type profiles, etc. The same applies to fasteners and any other structural elements. Also, when installing, it is necessary to closely monitor the quality of fastening guides, transverse and, in particular, reinforcing profiles.

- Application of unforeseen technology cutting profile

When mounting the frame for plasterboard, the length of the metal profiles used is somehow necessary to be adjusted. In no case can this be done with disco electric saw. With high speed of rotation cutting disk The profile will be heated and galvanized will be unworn at the cut place. In the future, this site will be subject to corrosion, which ultimately can lead to weakening and even the destruction of the structure.

- Extension of the walls of profiles

When the walls of the metal profile is extension, its carrying ability falls, which leads to a violation of the integrity of the construction during the trim or, which is much worse, after the finishing work is completed.

- Installation of GCL back to the outside

A gross mistake when creating designs from plasterboard is the use of the back of the sheet instead of the facial. If the GLC wall is, it will lead to the occurrence of irregularities and the inconsistency of the edges at the junction of the neighboring sheets. In the case of moisture-proof plasterboard, the facial part is specially protected from moisture and temperature drops, the facial part will not be able to perform its functions, which will raise the gypsum and the inevitable destruction of the structure in the future.

- Refusal of suspensions and intentional loosening of the frame

When finishing complex surfaces, it is often difficult to fix the profile system. It is very important to understand that with the weight of one standard sheet of 30 kg and not sufficiently reliable mounting the frame, the latter will not enough sooner. This can happen literally after the finishing of the drywall, that is, with the addition of additional weight of the finishing materials.

- Violation of the carcass scheme

If the profile step is chaotic, with too broad or, on the contrary, too narrow retreats from the walls and from each other, it will cause serious problems when installing and further exploited design. The latter can be elementary to prick, and drywall to crack, which is unacceptable. In addition, it will be necessary to perform a larger amount of work, of course, with additional consumption of material.

- Fastening GLC "in a row"

In the list of the most popular errors when installing plasterboard are mounting sheets in one row. The result is irregularities at the joints that cannot be eliminated when finishing and the occurrence of suture cracks. In order to avoid this, it is strongly recommended to install HCL into dispersion.

Mounting work should be started after all required calculations. In the process of manufacturing the frame and plating, leaf material should be checked both the reliability of the entire design and the correctness of the installation of the joints, the observance of angles, levels and linearity.

Shpotelka Shvov.

Little who will like the prospect of living in the middle of naked walls of a nondeshah gray or green drywall. Therefore, after installation, it must be prepared for subsequent finish. If the premises owner is going to paint the walls or glue wallpaper on them, you will have to go close to the joints. To do this, it is necessary to buy a primer, as well as a gypsum putty and the reinforcing grid (sperphanka). Before proceeding with work, you should make sure that all the self-tapping screws that GLCs were attached to profiles, drove the flush, and the sheets themselves are completely securely securely.

The places of non-original (cut) seams are processed by primer. Some wizards additionally expand the joints, however, this leads to an increase in the consumption of gypsum spacion mixture. Next to prepare a solution, after which it with a spatula is neatly applied along the seam line and on the hats of self-tapping screws. When choking non-original joints, it is necessary to use the reinforcing grid. It is applied to a fresh smoothed solution with a spatula.

The putty of plasterboard walls is always performed after completion of work with the ceiling construction.

Straight outer angles are closed using a special perforated corner, which is fixed with the solution. The latter, regardless of the location of the location, at the junction, the screw of the self-press or the corner seam - should be smoothed and completely close the metal. Laying the solution "Waves" and "Steps" is not allowed. After processing the joints, the entire plane of the wall or ceiling of plasterboard is performed, or special glue is fitted, which is glued to the wallpaper selected by the owner.

If the framework of the frame of the frame, its plastering and plasterboard putty was observed, the walls or ceiling of it will be visually indistinguishable from the usual. Upon completion of the finishing cycle of finishing works, the premises should only enjoy the beauty of the new interior.

Highlights when working with GLK, video

Work with plasterboard will help allow you to finish the premises at the highest level. Walls, applying such a material, you can perfectly align and hide everything visible and sometimes quite complex defects, and on the ceilings to create just excellent figures, adding some lighting to which can be made from the ceiling decorative masterpiece.

With the help of drywall, you can easily and easily create your own unique and unique interior. Can be separated by plasterboard with your own hands and concrete wallsAnd any others, while maintaining the quality of such a high level finish. All other, plasterboard sheets have excellent sound insulation indicators, as well as indicators for thermal insulation. Well, just an indispensable assistant at any kind of repair and finishing works, eh? To carry out drywall works, it is easy and running quickly, you will need to prepare a special tool.

Tool used when mounting drywall

For quick and unhindered work with such material such as plasterboard, it will be necessary to have a different type of tool, and its amount will depend on the method of mounting the plasterboard (on the crate, or using adhesive mixtures). For saving of space and time we describe the full range of tools that the same They will be good for working with clamp and with adhesive compositions.

So, drywall works will be required:

- Screwdriver, which is useful to install the frame of the crate and directly fastening sheets to this frame.

- A couple of small and medium sized spatulas to easily apply putty and glue.

- A spatula of the toothed side, which will be useful for applying adhesive composition on the surface of the drywall.

- Construction level, which will help make marking, if necessary.

- Cutting tool (a stationery knife or light hacksaw) for cutting material.

- Drill with various nozzles, which may be necessary for both making holes in the wall and for mixing the compositions of glue and putty.

Now that you have collected the entire set of tools that may be required when working with sheets of drywall and the implementation of the finishing works, it is worth considering the type of drywall and get acquainted with its characteristics.

A variety of plasterboard

It is worth noting that before purchasing required amount Sheets will need to do careful measurements of the room and calculate it (quantity). To the value obtained by every "fire" case (damage to the sheet, poor-quality sheet in the package, etc.) add 10% of the calculated quantity.

Now directly to the question. The production of plasterboard is now predominantly 4 species, each of which is intended for use in specific rooms with their special characteristics. Marking sheets of plasterboard for the purpose is unified, and you will not need to choose to break your head over why this sheet is green, and the one is red, and that these colors are generally significant.

- Gray color tells us that it is the most common, even the classic version of the sheet, which is suitable for use in rooms with moderate humidity of the surrounding air.

- Pink sheet color (sometimes black-red or purple) means that such a type of sheet is resistant to temperature and fireproof, and therefore, it will become the perfect material for plating the areas around the fireplace or stove.

Defined labeling (or notation) for each of the considered species. Thus, simple plasterboard is indicated as GKL, resistant to fire - GKLO, water - G CLEM, and the combined type, respectively, is Globo.

Additional consumables

For work with plasterboard and finishing, be it wall or ceiling, it will also be required in addition to the tool and the sheets themselves also purchase consumables. So, among them will be:

In order to carry out work on finishing or repairing with drywall, you will need to hold a number preparatory events. Let's see what exactly.

Preparation for work

Whatever work was carried out with plasterboard sheets: did you decide to separate the walls, the ceiling, or shelter the balcony, it does not matter, because the required surfaces will need to be in order. Calculated such measures for the preparation of surfaces to work are as follows: Cleaning the walls, sealing cracks And holes and processing with antiseptics and soil compositions. For the beginning of the work surface, it will be necessary to clean as much as possible from the old coating. The putty layer, whatever it seems reliable, it is recommended to remove under zero. Old wallpaper, old even plasterboard - everything will be required to remove. Such work is more convenient to carry out using a hard spatula and a roller, moistened with water. When the walls are detected in the surfaces of the walls or the ceiling of cracks, the holes will be deliberately cleaned to the base. All detected protrusions are better to dug the same, knock and process with primer or putty. After the surfaces are processed, it is recommended to apply a thin layer of plaster, which is designed to smooth out other small defects of surfaces. It is recommended to complete the preparation of surfaces. It is recommended to carry out additional processing with the compositions with antiseptic properties and primer.

Better primer antiseptic. Now, when the walls or ceiling are fully prepared for further work, you need to wait for a complete surface drying and only then continue facing or finishing work. Including the article Consider the two main method of fastening of drywall - with the use of framework and by glueing by adhesive compositions.

Methods for fastening drywall to surfaces

Produce mounting work With plasterboard, by applying adhesive compositions, much easier than when installing a frame from a profile, however, it should be understood that with this position, the additional installation of insulation and soundproofers is simply impossible. The process of gluing panels is as follows: the surface that we have already prepared previously prepared , We free, applying a plumb or level. If there are no irregularities, you will need to withdraw them for one level relative to the overall plane. It is possible to carry out such procedures as follows: slaves of solid adhesive composition are applied to the walls in certain places and the required quantities so that when attaching a sheet of drywall on them in a strictly horizontal or vertical position. Later, after complete drying, the sheet is fixed on these slaps using self-tapping screws. Such a measure will help to achieve a quality finish and give the walls even and smooth species (after fastening sheets, of course). The ground layer is applied on the entire surface, which should be thoroughly dry before the plasterboard will be attached to it.

After the primer is dried, proceed to sticking sheets. You should start from a long corner. The glue solution is applied to the opposite side of the sheet and is applied to the surface, while pressed tightly, but without special concentrated effort, because with such an effect, the sheet of drywall is easy to deform. After the sheet is applied, wait a while, while the surface and composition of the adhesive is captured, and proceed to sticking the next sheet. After work is completed, it is necessary to leave the room alone for a period of approximately day (and better, if there is no place to be in a time ). After this safe, you can begin the grout of the seams. When the seams are embedded, additional primer works are held, and after them - finish finish Spacure solutions.

The process of installation on the frame is inherently similar to the fastening process for glue. However, there is a profile that is fixed to the surfaces in such a way that one smooth and correct plane is created in the role of glue slap. Plus, this method of attachment of the plasterboard is that the framework allows you to place between profiles different kinds Insulation if necessary. All the difficulty lies only that the profile is set to one plane, which will help the level, plumb and rule. When the profile is installed, and the isolation is laid, you can start fastening sheets. They are fixed through a screwdriver and self-tapping screws directly to the online profile. All subsequent work: grout, primer and putty - similar on the principle of conducting previously described for the case of installation on glue.

Conclusion

The methods considered in the article and methods for installing plasterboard sheets on the surface: walls, ceiling - novice repairmen or those who started finishing work for the first time. Knowledge of the classification of sheets will be useful and the list of the necessary tools and requirements for the faced surface will help to reach a matter of the most responsible and be "in all weapons". Also I would like to note, and it is important to understand that despite all your positive characteristics, drywall It has both a high service life, and when appropriate operation and installation will become an indispensable assistant in creating a pleasant and cozy atmosphere in your home. All the best!

R

abote with drywall do it yourself is available to any person who has these most hands and quite a few skill with them to use! Which designs from drywall do it yourself can be easily implemented, we will tell here.

Content

1.

2.

3.

3.1

3.2

3.3

4.

5.

6.

The widespread belief that plasterboard is a new super-modern material that came to the construction site together with the 21st century - delusion. Material representing a composite sandwich from two layers of cardboard and a layer of gypsum between them, invented in the nineteenth century And quite successfully applied under the name "dry plaster" on the immense construction of the Soviet Union still in Khrushchev times.

Of course, since then the technology has undergone changes, and for the better. Today, working with drywall do it yourself is available to any person.

Facing with plasterboard sheets (GLC) can be performed by two main ways, on glue and by carcass. Here, just lies really serious innovation in construction. The fact is that if the plasterboard itself does not differ from dry plaster, then here is the material for the framework, i.e. The foundations for which this dry plaster are fixed, has undergone major changes, thanks to what work with drywall has become simple and affordable even for a non-specialist. The name of this miracle is typical metal profiles from galvanized iron.

Working with metal profiles for the framework of the frame and installation of drywall do it yourself

Metal profiles for the frame, in section reminiscent of the letter "P" changed wooden rails In the Russian market, first of all, thanks to the company Knauf. Therefore, the classification adopted abroad is widespread more than the name according to GOST. The main profile dimensions 6x3 cm is denoted by CD. Auxiliary profile, 3x3 cm -UD. The mounting profile, which is the main connecting element when the framework of the framework is called "direct suspension". These are the main profiles and creating drywall structures with their own hands, they are used most often.

Metal profiles for the frame, in section reminiscent of the letter "P" changed wooden rails In the Russian market, first of all, thanks to the company Knauf. Therefore, the classification adopted abroad is widespread more than the name according to GOST. The main profile dimensions 6x3 cm is denoted by CD. Auxiliary profile, 3x3 cm -UD. The mounting profile, which is the main connecting element when the framework of the framework is called "direct suspension". These are the main profiles and creating drywall structures with their own hands, they are used most often.

The complete range of profiles and components to them is much more extensive. There are rack profiles that guide profiles for a device of partitions (in foreign labeling UW; CW), as well as a variety of connecting elements for working with plasterboard, allowing you to quickly collect the most complex drywall designs with their own hands.

The main fastening element for frame profiles under GLCs serve a self-tapping screw for a length of 9 - 12 mm called on the construction jargon "Blug" or "Seeds". Along with self-drawing, rivets are used, as well as special mounting ticks that arise folded together profiles form an undeveloped connection. Each of these methods has its own scope, so work with drywall do it implies the possession of any of them. The plasterboard sheets themselves are fastened with screws for metal 27 mm long.

Here is the actual and all the main elements for working with plasterboard and the framework of the framework. It is still worth mentioning the fastening elements of the frame to the walls and the ceiling. They are not very much, the main serve as relatively recently appeared on the market. nails "Quick Installation", then a pair - a tree self-tapping screw and the so-called dowel - plastic plug where mentioned self-tapping screw and screws. This plug is installed in drilled hole Finally, various modifications of anchor are scoring, self-tight, which are crushed, recoverable and unacted.

Here is the actual and all the main elements for working with plasterboard and the framework of the framework. It is still worth mentioning the fastening elements of the frame to the walls and the ceiling. They are not very much, the main serve as relatively recently appeared on the market. nails "Quick Installation", then a pair - a tree self-tapping screw and the so-called dowel - plastic plug where mentioned self-tapping screw and screws. This plug is installed in drilled hole Finally, various modifications of anchor are scoring, self-tight, which are crushed, recoverable and unacted.

Many of us are confident that plasterboard - modern construction materialwho entered the use of only at the end of the last century. No! In fact, such material is used for about 200 years. Of course, during this time, production technologies have changed, but this does not cancel the following fact: to master the basic moments of passage with drywall can each can independently.

As a rule, today no one uses wooden bars for mounting the frame, instead, metal profiles of the P-shaped form are used instead.

Work with plasterboard occurs with 4 types of profiles.

- Guide profiles for creating a frame, they are also often called Mon or UW. They have a standard depth of 40 mm, and the width can be 50, 75 or 100 mm. Guide profiles are used to create the basis for fastening the rack and ceiling profiles.

- Ceiling guides (PNP or UD) have the same functions as previous profiles, but are used for mounting suspended ceilings.

- Ceiling profiles (PP or CD) are designed to create a frame and jumpers. They are inserted into the guides and fix the suspension, crabs, anchor clips to the ceiling.

- The rack profiles (PS or CW) are used when it is required to install plasterboard partitions or to create walls. They are fixed in guides.

The main fastening elements for the frame profile are self-tapping screws, the length of which is from 9 to 12 mm. Also there are rivets and mounting ticks (riveting) for connecting several profiles. The frame is attached to the wall or ceiling on the anchors or dowel-nails.

Do not be afraid of a large set of details used when installing drywall. This is not a complete list of what professional builders use. In addition, do not forget that one-time work implies only the presence of direct suspensions, CD and UD, dowel-nails or anchors.

Special attention should be paid to the tools for mounting drywall on the walls.

Since you have to drill holes in profiles, walls and other materials, buy or rent a perforator, the impact force of which is 3-5 J. With the help of the perforator, make a hole in the concrete much easier than the shock drill. She simply can not cope with so much holes. In addition, the perforator is perfect for kneading various mixtures for putty and mounting. This requires a special nozzle-mixer.

No less important is the rechargeable screwdriver with a set of special nozzles to screw the screws with different types of hats.

In addition to power tools, a manual tool is also used:

- a hammer;

- scissors for metal;

- screwdriver;

- stationery knife;

- markers;

- laser level or hydraulic level;

- plasterboard plates;

- passatia.

To attach one rack of the frame with a height of 2.5 m to the wall, direct suspensions are used in the amount of five pieces, that is, every 50 cm - 1 suspension.

To secure each, two anchors are used, you just need to drill 10 holes. The distance between the racks is 60 cm, so for the wall 6 m long and a height of 2.5 m, 7 frame racks and 70 holes will be needed.

How to work with plasterboard

Work with plasterboard is primarily the creation of a frame and its further covering. Usually, alignment of the walls, construction of partitions, arches and niches.

Installation of plasterboard with your own hands is as follows.

- Return from the wall at least 3 cm (profile width), and make marks: With a plumb or laser level Follow the line on which the wall from drywall will be located.

- Secure the main guides UD profiles on the floor and the ceiling. Their edge must go through your line.

- After that, it is necessary to set vertical racks from CD profiles. To do this, they are inserted into the guides and fasten themselves to each other.

- To make stiffness CD profiles, every 50 cm they are attached to the wall using suspensions that fasten with a wall with two dowel-nails. The suspensions are screwed to profiles with self-draws, and their corners are bend.

- The width of the standard sheet of plasterboard is 120 cm, so the distance between the CD profile centers is 60 cm.

- After mounting the frame, the insulation, electrical wiring, tap pipes or heating pipes are placed.

- When plasterboard sheets are installed on the ceiling, not only direct suspensions are used, but also wires and "butterflies", which have special steel "wings", fixing the removal at the desired distance from the ceiling.

Types of fasteners for creating a frame

Types of fasteners for creating a frame - It assumes that you are using special attachments for this - anchors.

- Self-tapping screws are screwed in 25-30 centimeters in increments.

If you want to cut off the sheet of drywall, it can be very easy to make it yourself. For this, the stationery knife cut the cardboard and several millimeters of the gypsum layer, and then donate it about the corner of the table. Second layer of paper cut after a donom.

How to seal the shelters

After the end of the installation is necessary. When the edge is kept, the edges should form the desired shape, and when mounting the sliced \u200b\u200bpieces, a chamfer is cut off to provide a triangular seam.

Use putty to fill the mounting seam. The junction place is enhanced by a painting grid (sickle). Serpenta is used after filling the seam with a putty, then it ships off. Reinforcing perforated corners can be used to enhance the angles.

If working with plasterboard requires creating curved structures, you can hit the sheet yourself. For this roller with spikes, sneak the sheet of cardboard and abundantly moisten it with water. After 10-15 minutes, the gypsum will turn, and it will be possible to give it any shape without any problems.

This technique is often used for and.

Now no repairs in the apartment do without that practical materiallike plasterboard. If you learn how to work with it correctly, you will have to create stunning designs to hide communications, creating partitions and zoning premises.