How to make a suspended sliding gate. Suspended sliding gates Sliding gates with top track

The classic double-leaf gates made of wood or iron are gradually becoming a thing of the past. They are being replaced by modern designs that are more convenient to use. These gates include hanging gates, which are equally appropriate both on the garage door and at the entrance to the site.

Hanging gates They are arranged according to the same principle as sliding ones, only instead of a rail, a guide is used in the construction of a suspended gate, fixed on the upper floor beam. Such gates are made of sheet metal or plastic. The gate wing moves along the wall or fence. Overhead gates can be manual or automated.

Pendant gate features:

- Hanging gates save space in front of the entrance, which is important with a small passage width;

- There is no need to regularly clear the driveway from snow;

- The gate is wind resistant;

- For the device of the gate, free space is required along the line of their opening;

- The upper squirrel, to which the rail is attached, limits the height of the gate;

- In winter, it is necessary to regularly clean the guide from snow.

Necessary materials, tools, purchased products

Due to its simple design, hanging gates can be made by hand. For this you will need:

- Metal pipe with square section 40x40 mm and 20x20 mm for the gate frame;

- Sheet metal, corrugated board or sandwich panels for the manufacture of the door leaf;

- Square pipe 120x120x4 mm for making supports and the upper beam;

- Track length twice the width of the gate (usually 6 m);

- Set of fittings for suspended gates;

- A set of automation for hanging gates, if you want to automate the process of opening and closing the gate;

- Welding machine;

- Bulgarian;

- Mortise lock.

The standard door width for passenger cars is usually less than 3 meters. If you want to make the gate wider, then to facilitate the construction, you can make them double-leaf, sliding in different directions. Hanging gate kits are sold ready-made, often with a rail. They are designed for a certain mass of the gate, so you need to calculate it before buying. If you are making double leaf gates, you will need 2 sets.

Automation for opening is also sold, depending on the required functions, its price fluctuates significantly, and anyone can choose a convenient option for themselves, or leave the gate without automatic opening, with a manual drive.

Gate frame

If the gate is made of metal, the frame is made of a 40x40 mm square pipe. Cut the pipe to the maximum overall dimensions, after which the ends of the pipes are cut off at an angle of 45 degrees. They are laid on a flat surface in the shape of the future gate, joining the corners, and fastened with spot welding. Measure the diagonals - they must be equal, otherwise the gate will skew. If necessary, the door frame is leveled by light tapping with a hammer. Boil the seams so that moisture does not get inside the frame. The internal dimensions are measured, after which the inner frame is cut out of the 20x20 mm pipe. Collect it in the same way as the external one and weld it to the external frame from the inside, aligning along one edge. They are cleaned from rust, scale and covered with a primer, and after drying - paint on metal.

For doors made of a sandwich panel, you can use an Ω-shaped frame, into the groove of which the panel is inserted. You can also use the profile for the gates made of corrugated board, but then you need to additionally reinforce the frame with a metal corner.

Fastening the door leaf and lock

The door leaf is cut according to the inner frame size so that it lies on the inner frame tube with a minimum gap. Fix the canvas to the frame with self-tapping screws or rivets. If the gate is made of corrugated board, then a profiled sheet with a wave height of not more than 20 mm is chosen so that it does not protrude beyond the frame. If you plan to install a mortise lock on the gate, you must immediately provide for its fastening.

The frame is required for gates installed at the entrance to the site. The frame is made of a 120x120 mm pipe by welding, while it must be remembered that the upper beam should extend beyond the doors to the width of their opening. In the case of single-leaf gates - the width of the gate to one side, in the case of double-leaf gates - half the width to each side.

The ends of the vertical support pipes are concreted into the ground to a depth of at least 1.2 meters. In this case, it is necessary to use a level - the skew of the upper beam can lead to spontaneous closing and opening of the unlocked gate. If the door is to be installed on a wall, you can simply fix the rail over the door opening and extend it along the free wall.

Installation of the guide and fittings

The guide is attached to the upper beam or wall using brackets so that its working part, on which the roller supports will ride, is turned down. The free end of the rail, equal to the door width, must extend beyond the opening. If a standard six-meter rail is not enough for this purpose, you need to weld a piece of the required length to it. The guide is aligned with the adjusting screws on the brackets using a level.

Roller supports are attached to the upper part of the gate on both sides of the frame - they are sometimes called trolleys. The gate is suspended by rolling the roller bearings inside the guide, after which the plugs that come with the kit are installed. If desired, a set of automation is installed and connected in accordance with the diagram given in the passport documentation. They put additional elements - a lock, a handle.

Hanging gates are reliable and modern; if used correctly, their service life is at least 15 years. In addition to hanging gates, cantilever gates can be made, made according to the same principle, but with a guide rail installed at any height. They differ from suspended ones in that they do not limit the height of the passage.

Do-it-yourself sliding suspended gates, the drawings of which are also often made independently, are installed in hangars, garages, warehouses. The classic iron and wooden homemade double-leaf gates have lost their popularity. They were replaced by new designs, which differ from rolling ones in that there is a guide in the suspended ones. It is attached to a beam at the top of the gate. Sliding gates have a rail on which they are able to move.

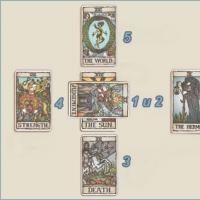

Picture 1. Construction of suspended sliding gates.

Features of sliding gates and tools for their installation

The main features include:

- suspended structures save space, this is very important when the passage width is small (image No. 1);

- there is no need to clear the entrance from the snow that has fallen in winter;

- the gate is resistant to wind;

- not very much space is needed to install the structure;

- restriction of the gate in the direction of their height;

- the guide will need to be cleaned of snow.

To install such a structure, you need diagrams and drawings, some tools:

- metal pipe, preferably square, its dimensions are 40x40 mm;

- corrugated board or other material for covering the canvas;

- pipe with a section of 120x120x4 mm for the manufacture of a beam;

- a set of accessories for gates;

- automation;

- welding machine;

- mortise lock;

- Bulgarian.

We make a gate with our own hands

Picture 2. Scheme of installation of rollers for sliding gates.

Gates are made with a width of no more than 3 m. This is the size adopted for an ordinary passenger car. The size changes if necessary. The pipes are laid on the ground and all distances are carefully measured, especially the diagonals. They are lightly welded in the corners and checked again. After all dimensions have been reached, the welding is done firmly. The seams must be applied in such a way that water does not get inside the frame. After welding the main size of the canvases, the inner bridges are inserted and welded.

After welding, all joints are processed with a grinder, the structure is painted with a metal primer, the outer metal sheets are welded. If it is a corrugated board, then it will be necessary to choose it with a wave height of up to 20 mm. Sheets can be attached to the frame with self-tapping screws. The locks must be fastened immediately.

The ends of the vertical supports must be dug into the ground and concreted to a depth of 120 cm. When installing, be sure to use a level. You can fix the canvas on the wall above the opening. The guide is attached to the wall with brackets. Roller supports are attached to the frame. The canvas is suspended, the rollers are inserted into the guide, plugs are installed (image No. 2). Automation and handles are mounted if available.

In general, the gate installation process is:

- Manufacturing.

- Choice of installation method.

- Manual installation.

- Monorail.

- Fabrication of the canvas.

- Installing the drive.

Canvases can be made of metal structures by welding. In this case, you need welding machine... They can be assembled from plastic, then the device will not be useful.

The installation method depends on whether the gate is operated manually or automatically. Manual way easier and much cheaper. For him, you need to purchase a special stainless steel guide, which will act as a monorail. You need to buy stops and metal rollers for it. The monorail is exposed using a level and welded to the embedded parts. The rollers are inserted inside, the ends are closed with plugs. This type of gate can be installed at the entrance to the suburban area.

Homemade products made using our own scheme, and even working as it should be - this is a reason for the pride of the owner.

The main thing here is not to forget about the path that the gate will take during its closing and opening. The road must always be clear for them. Hanging gates, drawings for which are developed independently, is not a very difficult business. Try it, do it - everything will work out.

Search better design such an obligatory element of the fence as a gate led to the emergence of several of its types, among which one of the most convenient options in operation, called a suspended gate. This so-called modification of sliding gates has become widespread for use in private construction for arranging the entrance to the territory of a house or summer cottage, and for industrial applications where hanging gates are used to enter protected areas, protect warehouses and hangars.

The principle of the device of suspended sliding gates is quite simple both in design and implementation. The door leaf is fixed by hanging it on a supporting beam, the height of which is the height of the door and limits the maximum height of the transported vehicle. Roller carts, which Basic structure the curtain of the suspended gate rests on the beam, ensures their free rolling along the beam and easy opening and closing.

For the manufacture of suspended gates, any materials used for the manufacture of these protective structures can be used, which can consist of either one leaf or two: metal carcass the frame of the leaf can be sheathed with metal, profiled sheet, protected by a decorative grill.

Modern suspended sliding gates by design features can be divided into:

- Suspended gates with one and two leaves, which can move in one direction or in different directions;

- A design with a manual drive, when the opening and closing of the gate is done manually. It is usually used where the gate is used infrequently, and they have a low weight of the leaf.

- Electrically operated suspended sliding gates with remote electronic or electric control, which allows for a comfortable passage.

Among the disadvantages of this design, one can name the limitation of the maximum height of the vehicle by the supporting beam and the requirements for the presence free space to roll back the gate along a fence or wall. However, this space is significantly smaller than what should be kept unoccupied in use. swing gates.

Accordingly, when installing such a gate system, you will save yourself the need to clear a large area of snow just to be able to open the gate. To ensure the free opening of the suspended gate, it is sufficient to clear the narrow space along the fence under the supporting beam.

In order for this type of gate to be reliable and easy to use, their design and installation should be entrusted to specialists with extensive experience in the implementation of such projects. When you need to install hanging gates, please contact MosKomplekt, and we will help you equip them quickly, efficiently and at the best price.

How to order the manufacture and installation of suspended sliding gates

To install hanging gates at your facility to protect the entrance to the territory, warehouse, garage or hangar, contact us for help, and MosKomplekt specialists:

- They will come to your facility to take measurements, select automation, help determine the type of cladding;

- Develop project documentation and cost estimates;

- The final project is agreed with the customer;

- They will manufacture all the necessary components and purchase the required materials;

- Deliver gate components and materials for their installation to your site;

- Assemble the structure, check and adjust the gate automation;

- They will hand over the work to the customer with the provision of warranty documents.

The prices for our hanging gates are determined individually after the development of the project and the calculation of the estimate. However, you can get acquainted with the approximate price for the manufacture of a structure, focusing on the average cost of our products, presented in the table.

The prices for our hanging gates are determined individually after the development of the project and the calculation of the estimate. However, you can get acquainted with the approximate price for the manufacture of a structure, focusing on the average cost of our products, presented in the table.

| Height, mm | Opening width, mm / price, rub | ||||

| 3000 | 4000 | 5000 | 6000 | ||

| 2000 | 98343 | 117621 | 136962 | 156177 | |

| 3000 | 114471 | 136836 | 159264 | 181692 | |

| 4000 | 130662 | 156114 | 181629 | 207081 | |

| 5000 | 146790 | 175392 | 203931 | 232407 | |

| 6000 | 162981 | 194544 | 226233 | 257922 | |

When you need high-quality, reliable and functional suspended gates, please contact MosKomplekt. The experience of our specialists, our own production base, as well as high-quality components will allow you to quickly obtain an optimal protective structure in all respects.

Operating principle suspension systems similar to recoil. The only difference is that the hanging door runner is attached not to the side, but to the upper floor beam. This design, like the sliding one, is created on the basis of simple console fittings, so it will not be difficult to make it without the help of specialists. After studying this article, you will learn how to make a hanging gate with your own hands in your home or in the country.

The principle of operation of a suspended gate

In fact, such gates are a kind of "curtain" that moves along the upper cornice with the help of a system of rollers on which it is suspended. In the role of a "curtain" can act as one, and two or even three leaves, which can roll in one or two sides or even move like an elevator door. Such mechanisms can be manually or electrically operated.Gate leaves can be made of any material: metal, corrugated board, wood, plastic, etc. The only limitation is that they should not be too heavy. Otherwise, you will need to install a very powerful top rail on which they will be suspended.

Hanging gates

The main principles of trouble-free operation of such devices are:

perfect balancing of the leaves: at their slightest distortion, the gate will open and close with great difficulty;

Correct selection of accessories.

Hanging gates. Installation procedure

1. Before installing the gate, the soil towards which the rollback will be directed is leveled.2. On both sides of the gate are attached vertical supports- metal pipes with square section, with a diameter of 20-40 mm. Since the upper beam will rest on such supports, the distance from the ground to the upper part of the support should be such that a car can freely pass through the gate.

3. For the installation of the supports, a hole is dug with a depth of 120-150 cm, into which it is lowered metal pipe, reinforcement is laid, and then the pit is concreted. The space between such a foundation and the ground is filled with crushed stone, while each layer of it is spilled with water and additionally compacted.

Concreting support pillars

Advice. To protect against moisture, metal or wooden plugs should be welded in the upper part of the metal support. This will significantly increase the service life of the supports and protect them from rust.

4. Swivel supports should be located strictly vertical... In the event of the slightest misalignment, the movement of the gate will be difficult or, on the contrary, they will open and close spontaneously. Therefore, when installing the supports, their location is carefully verified by the building level.

5. For top suspension beam a bent profile of a special shape is used (see photo). The size of its section depends on the weight of the suspended sashes. So, for sashes weighing up to 300 kg, it is enough to purchase a 40 × 35 × 2.5 mm profile. Heavy doors weighing up to 1000 kg will require a more powerful profile with dimensions of 90 × 75 × 4.5 mm. Moreover, its deflections are unacceptable.

Top beam profile

6. For a complete rollback of the sash, the length of such a beam should be 2 times the width of the opening itself. For standard garage doors its length should be equal to 6 m. If necessary, this size can be reduced.

Suspended gate arrangement diagram

7. For the installation of such a structure, the following fittings will be required:

Two trolleys (cantilever rollers) with a threaded axle;

Four brackets with a screw for attaching the rail;

Stoppers (limiters).

Carts with threaded axle

Components and fittings for the manufacture of suspended gates (brackets, hanging beam and cantilever rollers (trolleys))

8. Guide beam is fixed on the bearing support or on the upper part of the building wall using suspension brackets so that its lower working part, along which the rollers will move, faces downward.

Advice. If there is a weld in the beam, it can interfere with the free movement of the carriage. In order for the rollers to pass freely along the beam, it can also be positioned so that the seam is on the side.

9. No more than two roller carriages are required per blade of any size. The spacing of the carriages in this case depends only on the width of the web. First, their heels are cut off (the base on which the carts are mounted), and only then the rollers are welded to the sash frame... The door leaf should slightly overlap the opening (by 20 cm), and the distance between the soil and the sash should be at least 5 cm.

10. Then the door leaf is inserted by means of rollers into the upper suspension beam. To limit the movement of the sash along the edges, the beams are mounted on both sides plugs.

Suspended sliding system

11. To avoid swinging of the doors in case of wind gusts (this is possible if the gate height is too high), special restraints... They can be purchased ready-made or simply welded on pieces of reinforcement on the slit of the guide.

Stopper-limiter

12. In the presence of automation, it is connected in accordance with technical documentation and the diagram attached to it.

Advantages and disadvantages of hanging gates

The main features of such designs include:

Sufficient resistance to wind loads;

Less static effect on supports even with significant weight: the load is distributed more evenly in them;

The possibility of overlapping large openings up to 3 m wide;

Simplicity of construction;

Long period of operation;

The movement of standard sliding gates is carried out along the lower rail, which requires periodic cleaning from dust, dirt and snow ice; suspended structures are completely devoid of this drawback;

Significant space saving: unlike swing gates, no free space is required to open and close them; small space along the fence is required only for their rollback;

It is not necessary to open the gate leaf to its full width: for the passage, it is enough to slightly move the leaf.

Perhaps the only one disadvantage of such devices is the restriction of space from above, which interferes with the passage of large vehicles.

Video: Do-it-yourself hanging gates

The design features of sliding gates may vary depending on the version. However, in any case, the movable sash saves space and does not use square meters on the site next to the passage. When choosing, the height and width of the opening are taken into account, which allows you to choose one of the design options for individual requirements.

What are the types of sliding gates?

The movable sash on rollers is available in several versions:

- Suspended;

- Sliding, the movement of which is carried out along the rail;

- Console.

Each of the options has its own nuances of the device, pros and cons that do not allow them to be used in certain situations, but make installation possible in other cases.

Hanging gates

The device of automatic sliding gates of the suspended type differs from the other two options in the way of fastening the movable sash: it is connected to the upper beam, fixed at a level of 3-5 m. The installation height of the upper rail is determined by the type of object where it is used.

The design of sliding gates of this type is not very popular today, which is due to the limitation of the opening in height and as a result, not all vehicles can pass to the object.

As the name implies, the design of these roller gates is distinguished by the presence of a lower rail. The entire structure moves along this element.

Given the location of the guide (across the opening), a number of difficulties arise during the operation of sliding gates of this type: it is necessary to regularly clean the guide rail from dirt, snow (in winter period); the beam, even slightly, however, still interferes with the passage of cars. In addition, the design of such a movable section on rollers does not allow it to be used with a strong wind load.

Given the location of the guide (across the opening), a number of difficulties arise during the operation of sliding gates of this type: it is necessary to regularly clean the guide rail from dirt, snow (in winter period); the beam, even slightly, however, still interferes with the passage of cars. In addition, the design of such a movable section on rollers does not allow it to be used with a strong wind load.

Cantilever structures

This is the most convenient option for sliding gates in operation, because it does not provide for limiting the opening in height, and there is no guide rail from below.

Cantilever structures with middle rail

The structure is supported by a lower beam fixed on cantilever blocks (roller bearings). There are different versions of sliding gates of this type:

- The guide element is located at the bottom of the structure;

- Installation of the beam in the upper part of the movable sash;

- The guide block is installed in the middle of the sliding gate.

Construction and layout

To determine which type of movable sash on rollers and the method of fastening is more suitable for installation in your own summer cottage, you need to study all the versions. Considering that it is not always possible to clear snow outside the city, the design with a middle beam on rollers is the most preferable in these conditions.

Electric drive

The gate section can be operated both manually and by means of an automation unit. In the first case, provided that the installation is performed correctly, the efficiency of operation increases, then you will not have to make efforts to move the structure. The second design option simplifies the control task even more - it is enough to press a button for the mechanism to start working.

Considering that the guide block in this case is installed approximately in the middle of the movable sash, the automatic control unit can be positioned at a height.

Features of the device and functioning

For a complete understanding of what a section on rollers with a middle beam looks like, a diagram is presented:

Unlike the option when the guide is located at the bottom, in the considered version, double rollers are involved: at the top and at the bottom of the beam. They are smaller, which does not affect functionality. It can be seen from the diagram that this design option is distinguished by a slightly greater thickness. This is due to the fact that the supports are installed at some distance from the movable sash, because in this version the beam on rollers is located not under the gate, but next to it.

Fastening of the section in the buried state is provided by fittings: catchers (upper and lower), end roller. It can be seen from the diagram that as a guide block is used shaped tube with a closed loop, while the version of the door with a bottom beam uses a pipe with a slot for installation on roller supports.

For installation, it is necessary to prepare two free-standing pillars, up to about half the opening. For the rigidity of the structure, reinforcement or a channel is laid in the foundation. It all depends on the material from which the pillars are made.

If we compare all types of sliding gates, we can single out only a few of the features discussed above. In general, the principle of functioning of such structures is repeated: if you make an effort or press a button, the sash will begin to move along the fence. The lower catcher accounts for part of the load. This allows it to be distributed more evenly throughout the section.

The larger the roller unit, the larger the cantilever guides and the heavier the structure, the more the power of the electric drive must be.

If a drive is included in the design, the mechanism is stopped using limit switches. They are mounted on a toothed rack on either side of the beam.

For the installation of the gate, a similar technology is used: the site is marked; a base with reinforcement is being prepared (a frame made of reinforcement, with an embedded part); fasten supports for the guide beam (in the case when this element is located in the middle of the canvas). At the final stage, an automation unit is installed, the sash is fixed. The frame cladding for different types of gates is made in the same way.

How to determine the dimensions?

The dimensions of the sliding gates at the design stage of the fence are determined based on their own preferences. In this case, the scheme of the entire structure of the fence is compiled from scratch and you can correct it at any stage. However, in a situation where the fence has already been built, the main parameter is the width of the opening. It determines the dimensions of the movable section on casters.

Gate dimensions

The sash can exceed the opening width by 1.2-2 times. However, it is recommended to choose a sliding gate option that is 1.5 times wider. Then the section will have the most optimal sizes... If it is not possible to implement this solution, the door width can be reduced to a value that is 1.2 from the opening.

On average, the width of the car reaches 2m, you will need a little space on the sides so that the vehicle can enter without hindrance and another 50 centimeters.

Conditions that contribute to this: close location of the movable section to the end of the adjacent fence; uneven soil surface, which is why a stepped fence is being built.

The width of the opening depends not only on your own needs and preferences, since in some cases the street is too narrow and even a car will not be able to turn around. It is recommended to perform a test drive into the site through an impromptu gate. For this purpose, you need to drive two pegs into the ground. If the markings allow the car to turn freely, a diagram is drawn up and the arrangement of the fence and gates continues.

However, the greater the width of the passage, the more massive the structure will be, which will affect the quality of the fittings: for a heavy sash, reinforced components are used.

Drawing and construction of rollers

For a section on rollers with a middle beam, a retractable mechanism with hidden bearings can be used. This option does not require regular lubrication and is reliably protected from external factors... If we consider the version with a lower guide, then in this case rollers with hidden bearings are also used.

This reduces maintenance costs and also eliminates the need for effort to dismantle the structure for lubrication purposes.

Example drawing of a sliding gate

Drawing of sliding gates: The cost of sliding gates today is much less than in the old days, however, this design is offered at a higher price when compared with other analogues. But the installation can be done independently, provided that some installation rules are observed.