Articles about mechanized plastering of walls. Plastering machine as a way to save time and effort. How much does mechanized wall plastering cost - an overview of prices per m²

The work of a builder has never been easy, and finishing work has always been among the most laborious. But mechanization has reached this sector of construction, thanks to the fact that a plastering machine has appeared - there is no longer a need to perform a number of rather heavy operations with your own hands. Plus, a plastering machine can replace an entire brigade of finishers, which is very beneficial from an economic point of view.

Related articles:

Why is she good

Naturally, this is not an autonomous robot and the presence of a person is a must.

But, nevertheless, this unit took over the most difficult and routine processes.

- As you know, the preparation of a solution is a physically difficult process, the unit prepares everything itself.

- An important plus is that the machine accurately doses the amount of water and dry mixture, as a result we get a high-quality solution in a constant mode. The human factor is completely excluded, which is quite important in such works.

- Due to mechanical stirring and rapid feeding of the composition, the solution is saturated with air. The volume increases and this gives significant savings compared to by hand.

- A lot of time and labor is saved, the wall plastering machine replaces a small crew of workers and does the same job, but much faster.

- Since the mortar is applied quickly and evenly to the walls, it dries less.

As a result, the quality of finishing is significantly improved.

- In addition, a wall plastering machine is available to operate. The operating instructions are elementary simple, absolutely anyone can learn how to operate it. You don't need to be a professional finisher to do this.

- The unit itself has a relatively small size, plus convenient handles and wheels for transportation. As a result, a couple of adult men can deliver it with their own hands to any floor and to any point of the construction site.

- Most of the units are assembled from separate modules. This makes it possible to quickly assemble and disassemble the machine, which is very convenient for storage or transportation over long distances.

- In serial units, all the main processes are regulated, thanks to which the plastering machine can be used not only on large objects, but also on small small teams of contractors.

Highlights of the machine

How it works

- The unit requires an electrical network and water supply is desirable. If the construction site did not have a source of water supply, it does not matter either, serial units have a pump in their configuration that will supply water from any available container.

- Any machine has a hopper for loading dry mix, ready-made, factory mixes for plastering are loaded into it.

- From the hopper, the finished mixture is fed by a screw method into a special chamber for mixing with water. The mixing process takes place continuously and the finished mixture is immediately pumped into the distribution system.

Important: if the machine is turned off, there will be a minimum excess of the prepared solution - only what is left in the chamber and hose. All of them are easily produced when plastering problem areas.

- At the end of the mortar hose, a device is attached, usually in the form of a gun, with which the mixture is evenly applied to the wall. The plaster gun has, in turn, several modes of application, which are set depending on the type of surface and the consistency of the mortar.

- The units can be based on diaphragm, screw or piston pumps. There are 2 main types of devices AShS is a more autonomous system (stands for plaster mixing unit). The design is equipped with a cyclic block for continuous mixing of the solution.

- A more simplified system is represented by the ASh system, which stands for plastering unit. It requires a ready-made solution of the appropriate quality. This device is an earlier analogue of AShS and is profitable only for large construction sites.

Application technology

- Initially, thoroughly prepare the surface before applying the composition. The preparation process is carried out in the same way as with the manual application method. You should start by inspecting the surface and removing the old layer of plaster. There should be no paint or oil stains on the wall. The substrate must be dry, strong and clean. If fungus or mold is found, they must be removed.

- Further, in accordance with the type of solution, the surface must be primed. The primer is applied with a regular roller or brush. Beacons and corner profiles are installed on the wall before application. You can fix them with mortar or with mounting glue.

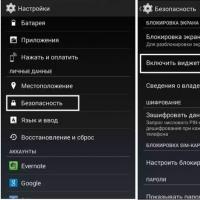

- Now the wall plastering machine comes into play. Each unit has its own instructions, in accordance with which it must be operated. After assembly and connection, check all hoses for kinks.

- After that, the operator stands at an angle to the work surface and begins to work. The gun is held in the leading hand, the other hand fixes the hose, it should not be pulled tight and experience tension in the docking station.

- Initially, deep depressions and cracks are filled, then the composition is evenly applied to the surface. Plastering is done from the left, upper corner of the room and gradually moves down and to the right.

- When working with a ceiling covering, start at the corner farthest from the window. The composition is laid in even strips about 70 cm long. The laying step is selected depending on the thickness of the application.

Important: when applying a thick plaster layer, as well as with the manual method, the plaster must be laid in layers. The interval between layers should be at least half an hour.

The video in this article shows the principle of machine plastering.

- The plastering machine is not the only technical miracle currently making the job of construction workers easier. For large volumes and large, flat areas, the plaster trowel has proven itself well.

- It is installed on beacons and fixed. Then the machine places the mortar in an even layer. The surface after such laying does not require additional leveling and grouting. But this unit can only work on a ready-made mixture.

- The solution can be prepared independently or used in combination with both devices, which automates the plastering process by at least 70%.

The video in this article shows how the plaster trowel works.

Important: at present, all units on the construction market operate on ready-made mortar or dry plaster mixes, combining them with water.

Hand-made machine

- Serial models of plastering units are certainly powerful, practical and high-quality... But the main disadvantage here is the price. They are quite expensive. Naturally, to perform a one-time job, a person will not buy an apparatus that is more expensive than all the work with the material. And it is not always possible to rent.

- But here, too, there is a way out, our land has not yet become scarce with talents. Further on your court will be presented homemade car for applying plaster. Of course, in terms of power and performance, it is inferior to serial models, but its cost is acceptable, plus it is quite simple to work with.

- As a basis, we will take a conventional fire extinguisher with a capacity of 4 liters, it has most of the parts we need, this is a handle, a solution bottle and a lever for opening the outlet valve. A large fire extinguisher will be too bulky, and a small container will need to be refilled frequently.

- First you need to cut off the bottom of the fire extinguisher. The self-made machine will work on the principle of a spray gun, so the fire extinguisher tank will serve as a hopper for the solution and will be in an upside-down position.

- A hole is drilled opposite the outlet valve and a metal tube is inserted into it, at the end of which a nozzle with a diameter of 4-5 mm is mounted. It will supply air from the compressor.

- The power of the device depends not only on the diameter of the outlet and air pressure, the gap between the nozzle and the outlet nozzle plays an important role. The closer the nozzle is to the outlet nozzle, the stronger the mixture will be ejected.

Advice: for plastering under a fur coat, 15 - 20 mm from the nozzle to the nozzle is enough, for fine-dispersed mixtures the nozzle should be located closer and the compressor pressure should be higher.

- You can, of course, sweat, cut a thread of the appropriate diameter on the metal tube of the air duct and fix the tube to the nuts through the gaskets. In this case, the gap will be adjustable or simply weld the connection.

- But the simplest solution is to secure and seal the tube with resin at the same time.

- For this, the fire extinguisher hopper, with a tube inserted into it, is installed so that the angle between the axis of the outlet and the horizon is 45º. The liquid resin is poured in such a way that its level does not reach the nozzle slightly, after which the fire extinguisher is left alone until the resin hardens.

- The resin pouring option is also good in that during operation, the solution flows along an inclined surface directly to the nozzle.

- Next, you need to get a compressor that creates a pressure of 2 atmospheres, connect the connecting hoses, fill in the solution and you can work.

The video in this article shows how a homemade wall plastering machine works.

Conclusion

The automatic plastering machine is good for professionals. If you are the owner of a construction company or just make a living decorating, then a wall plastering machine will increase your income at times. If you are covering your house yourself, then it is easier to rent a compressor and make a plastering unit from a fire extinguisher with your own hands.

The use of a mechanized method of plastering the surface allows you to get a perfectly flat base for further finishing in just one day. At the same time, the quality of wall plastering is much higher than when using the mechanized method. We will talk about how to plaster walls by machine method further.

Machine plastering by hand: features of the plastering machine

In the process of making machine plaster, a special device is used. Its main function is to mix the solution and ensure its high-quality mixing. As a result, it is possible to obtain an ideal composition for plastering in consistency.

The manual part of the work involves only filling the necessary components inside the device in the right amount. In the mixing part of the mechanism, the composition is kneaded, and the plaster is supplied to the surface from the storage hopper. With the help of a special nozzle, the composition is evenly sprayed over the wall.

This device has a rather complex structure, so it is rather difficult to make an apparatus for machine plastering with your own hands.

The person doing the plastering should only guide the hose away from the unit, ensuring that the wall is evenly coated in relation to the beacons. Excessive application of mortar reduces the strength of the plaster, and insufficient application of it leads to the appearance of gaps on the walls. Optimal value the spray thickness is 10 to 35 cm.

As part of the plastering device, there is always a reservoir, into which water and cement enters. Thanks to a specific program, the device independently controls the proportions of ingredients. Inside a special tank, the ingredients are combined with each other.

Special attachments significantly speed up the speed of plastering. The leveling of the compound on the wall is carried out with large spatulas. The speed of mechanical plastering is 5 times higher than manual plastering. In addition, two people are sufficient to carry out the work. One of them applies the composition to the wall, and the second evens it out.

You should start by measuring the curvature of the wall. For these purposes, use a level. On the outer corners it is necessary to install rails made of aluminum. Further, the work is automated and involves the application of the composition to the surface.

Initially, the device is connected to water and electricity. Further, the dry composition is poured into the inside of the hopper. Some machines for the production of plaster are equipped with a special pump that pumps water in the event that there is no centralized water supply on the site.

With the help of a feeding auger, the plaster is delivered to a special chamber in which it is combined with water. The machine, throughout the entire working process, carries out continuous mixing of the finished composition. Therefore, the quality of the mortar has very high technological characteristics, the composition has good adhesion to the base.

Next, the solution is transported through a hose to the surface. A spatula, trowel, as a rule, helps to level the mortar on the wall. The type of tool used is determined by the nature and location of the work. After leveling the surface, the solution is left to dry. To control the evenness of the application of plaster by machine, a level is used. In order to remove minor scratches, the wall is sanded with a special sponge.

Comparing the manual and mechanized method of performing wall plastering, the first has the following advantages:

- The solution is mixed and brought to the desired consistency by an automated method. At the same time, the physical costs for performing plastering are reduced.

- The consistency of the solution is the same at all stages of work. Since the machine is constantly stirring it. Therefore, the surface is not covered with cracks or irregularities.

- The mechanized method of plastering reduces the amount of mortar to be applied to the wall.

- The work time is several times less than when using the manual method.

- High quality plastered surface, smooth texture, no defects.

Mix for mechanized plaster - preparation features

There are two options for compositions for performing mechanized machine plaster: liquid and dry. With their help, it is possible to process surfaces of various composition, which are based on drywall, concrete, reinforced concrete, brick, aerated concrete. The temperature range for using the solution is limited to 5-30 degrees Celsius.

Initially, the surface should be treated with a primer that improves the adhesion between the wall and the plaster. After it dries, further work is carried out. The corner profile is fixed on an extra strong plaster mortar. Facade plastering involves the use of special mixtures on a cement-sand base. Water is used to dilute it. Special additives in the composition of such plaster are ways to regulate the level of its plasticity and hardening time. The same compounds are used for finishing swimming pools and rooms with high levels of humidity.

For performing internal plastering, compositions with a gypsum base are suitable. They set quickly, however, they are not suitable for rooms with high levels of humidity. The material allows air to pass through well, therefore, allows the walls to breathe. As a result, it is possible to obtain a perfectly even coating for further finishing.

When working with cement-sand compositions, it is necessary to wait until they are completely dry in order for them to gain strength. A composition that is applied by a machine is more fluid than that that is applied by hand. Since it must be sprayed over the surface.

Mechanical plastering of walls - technology of

The relevance of using the mechanized method of applying plaster is primarily justified in large premises. The process of their plastering lasts one or two days, while manually, it would not take even a week to complete it.

To perform mechanized plastering, you need a plastering station and a gun, which has a compressor that supplies the composition under pressure. As a result, it is possible to obtain perfectly flat walls, the plaster on which is durable and has a long service life.

The plastering station is an independent system within which the mortar is prepared. Then he gets to the gun and is fed to the wall. The dry composition is poured into a bunker container, which is filled with water. It is necessary to hold the gun firmly, as the solution is supplied under high pressure. The gun must be at right angles to the surface to be plastered.

Another option for performing mechanized machine plastering is the use of a cartridge pistol. This device does not prepare the solution on its own, but involves pouring the already prepared mixture into the top of the device. Next, the compressor is turned on, which sprays the solution over the surface. The pistol is constantly held in the hands and creates a high mechanical load on the person working with it. It is less convenient than a plastering station.

Another option for mechanized plastering is the use of a pneumatic shovel. The composition is thrown onto the wall thanks to a special steel container that scoops up the composition.

There are shovels for walls or for ceilings, in addition, they differ in relation to the shape, size and location of the buckets. The productivity of work with such a device is an order of magnitude lower than with a special station.

In any case, it is necessary to prepare the surface before applying mechanized plaster. The walls or ceiling are cleaned of dust and dirt, and beacons are installed. Next, the composition of the primer is applied, and then the corner guides are installed. Since they are made of metal, they must be treated with an anti-corrosion compound.

After that, plastering of the surface begins. Dry mixtures are placed in the machine bunker, the amount of water for most models of devices for performing mechanized plastering is determined independently by using pump station... The plaster is applied in a direction perpendicular to the walls. If there are surpluses, they are sent to a part of the wall that has not yet been filled with plaster or to hard-to-reach places.

Plastering is carried out after 3-4 hours from the moment it is applied to the wall. With its help, it is possible to get rid of significant defects on the walls and give them smoothness. Next, you need to wait until the composition is completely dry, which is carried out for three days. After that, proceed to the finishing plastering of the surface. In the presence of high humidity in the room, the drying time of the composition increases to seven days.

The hose from the machine must be guided along a line, the next line must half overlap the previous one. Thus, it is possible to achieve a uniform distribution of the composition on the wall and increase the smoothness of the coating. The lighthouses must be under the plaster.

If beacons were used, made of metal, then they are removed immediately after work is completed. This way the walls will not be corroded. To plaster the grooves under the beacons, use a hand tool.

The final stage is sanding the surface with a rubber float. The surface is moistened with water and rubbed. Thus, the use of a device for machine plaster greatly simplifies the process of preparing the solution and applying it to the surface.

Mechanized plastering technology

The process of mechanically applying plaster to walls consists of the following stages:

- Equipment transportation to the construction site. Installation and configuration of the station.

- Working on work areas: deleting old finish, performing grouting and priming of walls.

- Checking the walls for evenness using a level. Marking of places for plastering.

- Leveling the mortar on the wall, if necessary, reapplying and leveling the plaster.

- Finishing with a rule. Plastering the walls.

In the process of performing a mechanized plaster screed indoors, the air temperature for work must be at least +12 degrees. At the same time, the humidity level should not exceed 60%.

In addition, the room should have glazed window openings, a heating system, a leveled screed. Internal and external plastered surfaces must be protected from excessive moisture.

Mechanized facade plastering

The process of mechanized plastering of facades is quite complicated, and it is almost impossible to cope with it without work experience. Therefore, if you have not previously performed the plastering of walls in a mechanized way, then it is better to entrust this issue to professionals.

The initial stage of work involves a visual inspection of the work site. Determining the curvature of walls, taking measurements on the walls and setting angles. Next, the amount of material used in the work is determined and purchased.

At the next stage, scaffolding is installed, cracks are cleared and opened, if any. The surface is cleaned of dirt and dust, the facade is washed and dried. To protect the facade from moisture, mildew and mildew, as well as to ensure tight adhesion of the plaster to the wall, a primer is applied to the surface in two layers. Further, if necessary, a reinforcing mesh is mounted and beacons with corners are installed.

You also need to set corners on the windows. Plastering is done from bottom to top. With the subsequent leveling of the newly applied solution. After the mortar has set, it is necessary to get rid of the beacons.

Automatic plastering of walls is the process of applying a leveling or decorative layer of material using special equipment. Plastering machines themselves prepare the solution and spray it on the treated surfaces, and the worker only controls this process. The finishing work carried out with the plaster station is suitable for almost any construction or renovation project. This can be a minor cosmetic repair in a small apartment, capital work on the alignment of internal or external surfaces, and so on.

If we talk about the positive aspects of this method of conducting finishing works, then the following are especially highlighted:

- High performance. Typically, processing a certain area takes 7 times less time than manual plastering.

- Profitability. The automated process requires no more than two employees, so you don't have to pay to hire a whole team of specialists. There is also significant material savings.

- Coating quality. The mixtures that are made in the plastering machine are homogeneous, so they can be used to create a strong and durable coating. Also, if the technology of applying the material is observed, there is no need for further actions: applying putty, greasing, and so on.

Plastering machine increases productivity several times

Plastering machine increases productivity several times Mixes for automated application

The compositions that are used for application by this method are distinguished by a relatively short drying and curing time, high adhesion rates, good sound and heat insulation performance, as well as an excellent level of vapor permeability. The automated application method improves these characteristics and creates a comfortable indoor microclimate.

For external works on leveling the facades of buildings, a conventional cement-sand mixture is used. For finishing the interior surfaces in dry rooms (bedrooms, living rooms, children's rooms), gypsum plasters are most often used. As for bathrooms and kitchens, mixtures with polymer additives or based on acrylic resins are recommended. Most of the ready-mixed mixtures that are supplied already diluted with water can be used for both manual and machine methods. Modern materials also contain substances that significantly increase the viscosity and plasticity of ready-made solutions.

For the machine method, you can use the usual mortars of cement-sand and gypsum plaster

For the machine method, you can use the usual mortars of cement-sand and gypsum plaster

Main types of devices

For automatic plastering, you need a wall plastering machine. If we are talking about a large object with a significant area, then it makes sense to purchase this equipment. For short-term or one-time use, such a purchase is unprofitable, so it is better to rent the equipment.

Pneumatic shovel for mechanical method

Such a plastering machine can be equipped with nozzles of different diameters, depending on the type of mortar used. The machine itself is a metal container for the diluted solution. It is equipped with 4 air nozzles and the same number of material devices. Direct feeding to the surface is carried out through a special tube, which is covered with elastomer or other non-slip material to make it easier to hold the tool with your hands. Also, the tube is equipped with a valve that regulates the supply of air under pressure.

Wall and ceiling pneumatic plaster shovel

Wall and ceiling pneumatic plaster shovel Working with such a device is quite simple: you just need to direct the tube to the surface to be treated and move it from side to side, while pressing the solution delivery button. The average productivity is 60 square meters per hour. Different models of this equipment are used for processing walls and ceilings. They differ in the location of the container relative to the feed tube.

Air gun

The machine for plastering walls of this type is a short nozzle barrel, on which there is a threaded connection for installing nozzles. Various nozzles provide the required spray rate for the work material. There is a metal or plastic container at the top of the device. Its volume may vary, but in most models it is 5 liters. Modern models such a device is equipped with a trigger that controls the supply of plaster to the surface to be treated. The gun looks like an airbrush. In its lower part there is a hole into which the compressed air supply hose is inserted.

Air plaster gun allows you to spray mortar with different intensities

Air plaster gun allows you to spray mortar with different intensities

Such equipment is supplied with a set of nozzles that allows you to work with solutions of various consistencies. The main advantage of this unit is the ability to adjust the degree of spraying and the intensity of the supply of the working substance. This feature makes it possible not only to rough out the walls, but also to apply a finishing decorative layer.

Plastering machines

The modern construction market offers a huge number of different models of small machines and dimensional machines that are used for mixing and applying plasters. They differ in size, performance, equipment and, accordingly, cost. The market leaders are considered devices manufactured at German factories. The main feature of this technique is the possibility of not only plastering, but also staining.

As for domestically produced cars, they are easy to recognize by their considerable size. With their help, you can apply starting leveling layers of plaster and putty. The plastering machine can be used for the treatment of walls, ceilings and the arrangement of self-leveling self-leveling floors.

The medium-class plastering machine is in most cases compact in size. One person is usually enough to work with it. This equipment is equipped with a pump, which is the main working body. It is used for mixing, feeding and spraying material onto the work surface. This type of plastering machine is designed for materials with a grain size not exceeding 2 mm.

Some units are equipped with separate containers for water and dry mix, as well as for mixing. The solution preparation process is fully automated and is carried out according to a predetermined program. This ensures the high quality of the resulting solution, its compliance with the required proportions and the absence of lumps and air bubbles.

Modern plastering machines are compact in size

Modern plastering machines are compact in size Diversity on the market

The modern construction market is literally filled with equipment of this type. But there are several brands and models that, according to numerous customer reviews, do the best with the tasks assigned to them.

The best are the models of the German manufacturer Knauf. The advantages are high speed of operation, compact size, relatively low power consumption, and versatility. The disadvantage is the high cost.

Russian equipment Afalina ShM-30 can be used for both plastering and puttying. Equipped with a container for diluting dry solutions with water. Great for arranging bulk floor coverings and rough processing of walls.

Afalina ShM-30 - Russian-made plastering machine

Afalina ShM-30 - Russian-made plastering machine The automatic plastering machine PFT Ritmo M is the most compact version of equipment for plastering works. The analogs of the device are PFT G4 and PFT G5 SUPER. The equipment is used for plastering surfaces, applying paints and arranging self-leveling floors.

Manual machine USHM-150 is a universal equipment used for the preparation and application of various kinds of mixtures. With this unit, you can carry out work on leveling and painting various surfaces. This model is absolutely safe and reliable equipment that even a beginner can work with thanks to a simple control system.

Self-made installation for applying plaster and other mixtures

If you want to save even more money, and also at hand workplace with a set necessary tools and supplies, then you can make a plastering machine with your own hands. It is recommended to use an old, discharged fire extinguisher as a blank. This blank is best suited because the fire extinguisher is equipped by default with the components required for the plastering machine: a trigger handle, a nozzle and a holding handle.

The first step is to cut off the bottom, while removing a small part to save more volume. After that, you need to turn the cylinder upside down and fix it in a vice. A hole must be made in the wall opposite the trigger, into which the air supply tube will then be inserted.

The power of the device is influenced not only by the performance of the compressor, but also by the diameter of the outlet nozzle, as well as the distance from it to the compressor valve. To increase the power of the machine, push the compressed air pipe as far as possible. Ideally, it should be located approximately 2 cm from the outlet. The smaller this distance, the more the working material will be sprayed.

To do without using welding machine, you can apply one trick. To do this, position the cylinder at an angle of 45 degrees and pour hot resin over the insert section. Once cured, the resin forms an inclined surface that will provide a smooth transition. The main thing is not to clog the outlet.

A good compressor is necessary for the quality work of a homemade plastering machine.

A good compressor is necessary for the quality work of a homemade plastering machine. At this stage, the main work can be considered completed. It remains only to purchase a compressor that will pump air. It is connected to an embedded air supply tube. A pressure of 2-3 atmospheres will create a "fur coat" surface. If the pressure is increased, the material will fit more tightly.

Working with machines for applying plaster

The first step is to mix the solution. It is important to remember that the consistency of ready-made mixtures for manual work is not suitable for automatic application, therefore it is better to consult with the seller before buying.

If a dry mixture was purchased, then it is better to dilute it not with plain water, but with milk of lime - this way the surface will be stronger. The most commonly used cement-sand composition. To make it, you need to take 1 part of cement and 3-4 parts of yellow river sand. It is necessary to dilute to the state of thick sour cream, if you make the material too liquid, then it will splash heavily and hold poorly. At the very end, you need to add plasticizers to increase the viscosity of the material. Further work goes in the following order:

- The first step is to fill the container about three quarters of its volume.

- Then position the compressor so that it is convenient to work, and then raise the sprayer.

- Aim the gun at the surface to be treated, only then pull the trigger, while the distance from the wall to the nozzle should be about 30 cm.

- After the end of the first pass over the entire area of \u200b\u200bthe wall, you need to level the coating with a rule.

- After half an hour, you can start applying the second layer.

Plastering the surface with a plastering machine

Plastering the surface with a plastering machine - If gypsum mortar is used, it is better to work in pairs. The fact is that such substances freeze rather quickly. Therefore, one person applies, and the second immediately smoothes.

- Work should be carried out at a temperature of 15 to 30 degrees. Air humidity should be 70-75%.

- For facade works it is better to use plaster based on cement or acrylic. Inside, gypsum compositions are well suited.

- Decorative plasters are best applied with machines equipped with wide nozzle attachments.

Gypsum plaster dries quickly, so it will be more rational to work in pairs

Gypsum plaster dries quickly, so it will be more rational to work in pairs Applying plaster in an automated way is a fairly simple process that even a novice master can handle. The main thing is to think in advance what kind of material you plan to use, and then select equipment taking into account its features.

Plastering work is one of the most difficult to repair. The technique for plastering surfaces allows you to get rid of manual labor when performing complex operations. You can buy a ready-made plastering machine, and if you want to save money, make it yourself.

Will one machine replace the construction crew?

The main advantage of using technology is the release from routine manual labor. True, a machine cannot completely replace a person, but it greatly facilitates and speeds up the process. There are a number of advantages that speak in favor of using specialized equipment:

- 1. Preparation of plaster mortar requires an exact ratio between dry mixes and water. If a person can make a mistake, then the machine, observing the exact dosage, prepares high-quality mixtures on the machine.

- 2. Mixing of mixtures is carried out mechanically. It is difficult for a person to stir the solution, it takes a long time. The machine does the batch quickly. Due to the accelerated flow, the solution contains a large amount of air, which makes it possible to save money, since at the same cost, more solution is obtained.

- 3. One plastering unit can replace an entire construction team. In this case, the process proceeds much faster, and a uniformly applied thin layer of solution dries better.

That is, time is saved, and less material... A high-quality and durable coating is created that does not require puttying and further finishing work to level the surface. The technique is easy to operate. The operating rules are described in the instructions that are attached. Therefore, a person of any training can work with the device. The dimensions of the machine are small, special handles and wheels make it easier to transport equipment to the place of work.

The unit consists of separate modules, which makes it possible to assemble and disassemble it for transportation over long distances and storage. The serial machines have the ability to adjust work processes, so they can be used both on large construction sites and for small amounts of work.

How the miracle unit works and how to choose a solution

For the smooth operation of the device, constant access to the electrical network is required. Plumbing is also required in certain circumstances. If it is absent at the construction site, a pump is provided in serial devices that allows you to pump water from any container. For mixing the mortar, plastering units are equipped with special hoppers, into which dry mixtures are poured. They are loaded with ready-made mixtures coming from the plant.

After the hopper, the mixture enters a special chamber by a screw method, where it is mixed with water. The process is ongoing. The ready-made solution is immediately fed through the mortar hose to the distribution system. At the end of the hose is a special plastering device - usually a gun. With its help, the solution is applied in a uniform layer of the required thickness. Plastering guns support several application modes. The choice of the mode depends on the consistency of the solution and the type of work surface.

Solutions that are used for machine application have the following features:

- short drying time;

- quickly gain strength;

- good adhesion to the treated surface;

- good heat and sound insulation characteristics;

- high vapor permeability.

If the mixtures are applied in an automated way, their characteristics are improved, which makes it possible to create an optimal microclimate in the room.

To level the walls of buildings from the outside, a conventional cement-sand mortar is used. For residential premises (living rooms, bedrooms, children's rooms), gypsum plasters are used. For rooms with high humidity (kitchens, bathrooms), we recommend taking mixtures based on acrylic resins or in which polymer additives are used. Ready-made solutions are supplied already diluted with water, they can be applied immediately both by machine and by hand. Modern blends contain substances that increase the plastic and astringent characteristics of ready-made solutions.

Plastering shovels, pistols and cars - which technique should you prefer?

For the automatic application of mortars, special plastering units are used. Since this is an expensive equipment, its purchase is economically justified for performing large volumes of work. For one-time use, it is more profitable to rent equipment. There are several types of devices for mechanized surface treatment.

The pneumatic spade for applying mortars to walls and ceilings is a metal container for ready-made mortar, equipped with four nozzles for air supply and four for supplying a mixture. The diameter of the nozzles depends on the type of solution used. The plaster is supplied to the surface through a special pipe. The tool has a valve that regulates the supply of air under pressure. On average, up to 60 square meters can be processed per hour. For plastering the ceiling and walls, different models of pneumatic shovels are used. They differ in the location of the container with the solution relative to the tube through which the supply is carried out.

The pneumatic pistol is equipped with a nozzle barrel with a threaded connection, onto which nozzles are screwed. The differences between the nozzles are in the degree of spray of the plaster mixture. The container with the solution is located in the upper part of the unit; it is made of metal or plastic. The volume varies, but is usually around 5 liters. The solution supply is controlled by means of the trigger. At the bottom of the gun there is a hole for connecting a hose through which compressed air is supplied. Thanks to the nozzles, you can use solutions of different consistencies and spray the mixture with different degrees of intensity. This feature of the gun makes it possible not only to perform rough plastering of the surface, but also to apply the finishing layer.

Plastering machines are on the construction market different models, differing in equipment, dimensions, performance and price. The middle class plastering machine has small size and can be serviced by one person. The main component of the device is a pump that provides preparation, supply and spraying of the solution onto the surface to be treated. The granularity of mixtures for aggregates of this type should not exceed 2 mm. Depending on the design, some machines are equipped with separate containers for dry composition, water and mixing. The process of obtaining a solution is completely mechanized and is set by a special program. This makes it possible to obtain a high-quality mixture with exact proportions without air bubbles and lumps.

We make our unit from a fire extinguisher - according to the principle of a spray gun

If the purchase of a ready-made plastering unit is unprofitable, you can save money and make an application unit. The basis of such an apparatus is a fire extinguisher with a cylinder of about 4 liters. Such a blank has everything you need to create a machine for spraying the mixture: a nozzle, a handle, a lever that opens the hole at the exit.

First of all, it is necessary to cut off the bottom, since in the future the apparatus will need to be held with the nozzle down. The cut-off cylinder acts as a hopper. The only thing that needs to be supplemented with a homemade sprayer is a tube, through which compressed air will be supplied. It should be cut into the side wall of the cylinder opposite the valve outlet through which the mixture is sprayed. The device works on the principle of a spray gun. Compressed air is supplied from the compressor. For good spraying, the nozzle diameter should not exceed 4-5 mm.

On power homemade device influenced by the following factors:

- nozzle diameter;

- the distance between the nozzle and the compressor nozzle;

- supply air pressure.

To increase the power of the jet, the air supply tube must be as close as possible to the outlet valve. If the plastering is carried out "under a fur coat", then the distance should be no more than 1.5–2 cm. For fine solutions, the distance should be further reduced. The smaller the gap, the more powerful the jet will be. It is important to increase the pressure.

You can fix the tube using nuts with gaskets, then it is easier to adjust the distance, and the connection needs to be welded. There is another option without using a welding machine - fixing with resin. This will not only secure the tube, but also seal it off. To do this, the tube must be fixed at an angle of 45 degrees with the axis of the outlet hole and with the ground. The resin is poured in liquid form so that the final level is below the nozzle. Filling with resin is beneficial in that the liquid flows down the inclined tube to the nozzle evenly. Care must be taken not to block the outlet. Then you need to wait until the resin hardens.

At the final stage air compressor connected with a hose to the nozzle hole. To operate the apparatus, create a pressure of 2 atmospheres. With a little pressure, the finish is rough, suitable for a fur coat. A smoother coating with filling of all pores is obtained with more high pressure.

The right technology + good apparatus \u003d perfectly flat wall

Before starting finishing work, the work surface requires preparation. The surface must be cleaned from the remnants of the previous finish. It should be free of wet and oily stains. If there was fungus and mold on the walls, it is necessary to treat it with special means. The prepared surface must be flat, firm and dry. Apply a primer to the finished work surface. When the coating is dry, you can start plastering.

First, prepare the solution. It is better to dilute the dry mixture with milk of lime rather than water, then the coating will be more durable. The cement-sand mixture is diluted in a standard way: 1 part of cement and 3-4 parts of river sand. The solution should turn out like thick sour cream, it should not be too liquid. At the final stage, when kneading, we add plasticizers to increase the viscosity. If you use factory plastering equipment, then an instruction manual is attached to it. Check for kinked hoses before operation. Using homemade apparatus the sequence of actions is as follows:

- 1. Fill the container with the solution by 2/3.

- 2. Stand at an angle to the surface to be treated. The leading hand holds the gun while the other hand holds the hose. The hose should be long enough to move freely along the wall.

- 3. Squeeze the trigger only with the gun pointed at the surface. The distance from the treated surface to the nozzle is at least 30 cm.

- 4. The jet should be at an angle of 90 degrees with the wall surface. When plastering the ceiling, we direct the stream at a slight angle away from ourselves, applying the solution in a thin layer.

- 5. Start applying the mixture from the corner, filling cracks and depressions first. Apply strips about 70 cm wide.

- 6. Apply each subsequent layer after half an hour, especially if lime is present in the solution.

- 7. The number of layers depends on the thickness of the plaster to be obtained.

A plastering machine for mechanized wall decoration helps a person get rid of hard manual labor. This is especially important when carrying out repair work on a large facility in a short time. Plastering with an apparatus is the process of leveling walls with special mixtures. It allows you to replace do-it-yourself work with mechanical method, while preparing the mixture and applying it to the surface.

If during manual operation:

- The mixture needs to be cooked in small portions due to its fast solidification, in about 50 minutes.

- Operations are slow.

- Even a fairly experienced plasterer cannot prepare a solution of the same consistency every time.

- It is not possible to apply the mixture simultaneously to the entire surface:

- the solution is kneaded;

- pounces on the wall.

As a result, part of the wall practically dries up, the second dries up, and only pounces on the third solution. As a result, the surface is scaly, which over time can lead to irregularities and cracks.

Unlike the manual process, the mechanized one allows:

- Apply quickly and evenly.

- Get better surface finishes.

- Save solution - it is used much less... This is due to the fact that when stirring the unit, the mixture is saturated with air, this increases the volume of the solution.

So, for hand plaster for finishing one square meter area requires about 16 kilograms of solution, and when using the apparatus - 13 kilograms. Saves 3 kilograms per layer. When three layers are applied, this difference is already 9 kilograms, which means that the price of the material will be lower.

- Treat facades and walls in a shorter time, which significantly increases labor productivity. The device applies the solution to the surface much faster. This allows a wider trowel and a longer rule to be used than when working by hand. The wall surface is smoother, which is very important for further surface finishing.

The principle of operation of the unit and the technology of applying the solution

The main element of the plastering apparatus is a container:

- Water enters it and a dry mixture is poured. The proportions of the materials are programmed, which allows you to obtain a solution of only the desired consistency.

- Here the composition is thoroughly mixed, loosened, saturated with oxygen.

Then:

- The mixture is applied through hoses to the surface.

- The use of special nozzles allows you to cover a large area in a minimum time, and large sizes rules and a spatula to level this surface in a few minutes.

Tip: When mechanized plaster one or two workers can complete a large amount of work, up to five times faster than manually.

Plastering instructions include:

- The level measures the curvature of the walls.

- At the outer corners, guide beacons made of aluminum are installed. These works are done manually.

- The device is connected to the mains and water supply.

- The dry mix is \u200b\u200bpoured into the hopper of the plastering machine.

Advice: If there is no water supply at the construction site, you should use the pump included in the equipment set. It supplies liquid to the hopper, regardless of the type of container.

- The feeding auger delivers the plaster mixture to the mixing chamber.

- The composition is thoroughly mixed with water until a homogeneous consistency is obtained.

- Stirring occurs constantly during the entire operation of the machine, which makes it possible to obtain a solution of a sufficiently high quality.

- The mixture flows through the mortar hose onto the surface to be treated and is evenly applied to it, as shown in the photo.

- The mortar on the walls is leveled with large spatulas, a trowel and a rule. In this case, the surface is rubbed until it is even and smooth.

- The plaster mixture on the walls is left to dry.

- Other sections of the wall are prepared for finishing, the corners are adjusted.

- All stages of the machine plastering process are controlled by building levels.

- The last operation - the elimination of small scratches and protrusions, grouting the surface with a special sponge.

What mixture is used for devices

For plastering machines, mixtures are produced:

- Dry.

- Liquid.

They can handle surfaces from:

- Drywall(see How to plaster drywall and whether it is necessary to do it).

- Concrete.

- Reinforced concrete slabs.

- Brickswhich could be:

- silicate;

- hollow;

- ceramic.

- Aerated concrete.

- Aerated concrete.

Tip: The prepared solution must be used at a temperature between 5 ° C and 29 ° C. Before the start of the plaster, a primer is applied corresponding to the type of surface to be treated.

Besides:

- Used by special composition plasters for fixing the corner profile.

- For facade plastering, the mortar is made from mixtures that are intended for this type of work.

- For interior decoration it is better to use gypsum-based mixtures. They are used to level the surfaces of ceilings and walls in rooms with low humidity. Gypsum plaster allows the surface to be made smoother, smoother, more durable and environmentally friendly.

How to make a plastering machine

A homemade plastering machine, like an industrial unit, allows you to apply the solution faster and better than manually. One of these might be a homemade air bucket or a small hopper.

This, not very complicated, device allows you to apply the solution to the walls practically without losses, very quickly, without special preparation. As additional material for self-manufacturing of the device, a video is offered in this article.

Tip: A device of this type is intended for finishing large areas, for plastering the entire building. With small volumes of the treated area, it will take more time to install the device, and at the end of the work, its subsequent washing.

The advantages of the device, compared to the manual process, are:

- The rate of application of the solution increases by about 2.5 times, without loss of coating quality - the created jet pressure promotes adhesion.

- Finishing can be done using different impurities and fibers.

- The solution can be applied to walls indoors and outdoors.

- The device is easy to clean. For ease of maintenance, the container is best made of stainless or galvanized steel. Pneumatics just need to be blown out with a working air stream, after which all parts must be dried.

To make such a pneumatic mechanism, first of all, you need to understand on what principle it works, which will facilitate the assembly of the pneumatic bucket.

The action of the device is performed in the following sequence:

- From the compressor, a stream of air through a hose enters the bucket, which is filled with solution.

- On the opposite wall of the tank there are holes for pushing out the mixture under the pressure of air.

- The front wall of the bucket is made with a slope, this will allow the mixture to be scooped out more efficiently from the container where it has been prepared in advance.

Tip: To prevent the solution from spilling over when applied to the ceiling, a small cover should be made on the top of the hopper, which will cover only a third of the hole on the side from which the air will be supplied.

- A nozzle is put on the pneumatic hose, which serves as a nozzle, its inner diameter should be 5 millimeters, and the diameter of the outlet hole should be 12 millimeters.

- The nozzle is adjusted so that from it to the front wall, or to the outlet, the distance is approximately 20 millimeters. In this case, the lower part of the bucket can be much larger: 50 × 50 millimeters or 70 × 70 millimeters.

- The material for the manufacture of the structure is selected from the most different, from any available parts. It is important that the principle is respected: the solution goes down through a narrow space and is pushed out by air.

For example, with an increase in the distance to the front wall from the nozzle, up to 100 millimeters, almost all the pneumatic power will go to the resistance of the solution, and only bubbles and too little outflow of the solution through the outlet hole will be observed at the top of the container.

- On the sides, the bucket is fixed with two clamps attached to the edges of the hopper and the nozzle itself. In this case, the bucket has three fulcrum points. The clamps can be welded, riveted, the front must be fixed to the threaded connection.

Advice: When plastering with a bucket, a thicker mortar is required.

- A pistol is connected to the compressor through a hose, in this case a pressure of two to three atmospheres is required: with a larger value, the spray will inflate, with a smaller value, there will be no jet.

- When plastering, the distance to the outlet from the wall is approximately 18 centimeters, and the layer thickness is adjusted as needed.

Tip: To increase the speed of work, you should make more nozzles and outlets. In any case, the hose remains alone.

Use of any mechanical apparatus facilitates the process of plastering surfaces.