The device, selection and manufacture of a jigsaw machine. Homemade jigsaw machine for sawing: drawings and videos Stationary jigsaw machine

Without a jigsaw, many woodworking operations are impossible. Compact and lightweight, it allows you to manufacture products of even the most complex geometries. Sometimes, for example, with large amounts of work, it is more convenient to work with this tool not as a manual jigsaw, but in the format of a machine tool. Such equipment is presented in the catalogs of many manufacturers of household power tools, but if necessary, it can be made independently.

Equipment selection - main points

To begin with, it is worth answering the question: with what material will the master work most often? Motor power of 50-90 watts is sufficient for most types of wood, but if you are going to process hardwood and significant volumes, look for options in 120 watts. Stepwise adjustment of engine speed ( saw blade speed) is desirable, choose models with a smooth change in this parameter.

The ability to adjust the speed is needed to adapt the machine to work with different types of wood - heating of the material is excluded, which will spoil the cut. In addition, by gradually increasing the speed, the master concentrates on a complex procedure, and the engine also operates in a gentle mode, which increases its resource.

Some models provide for the possibility of cutting not only in a horizontal surface, but also at an angle, and a special scale will allow you to choose the most accurate position of the workpiece. Semi-professional and household machines allow you to change the tilt of the desktop up to 45 ° in one direction, professional - up to 45 ° in both directions.

Pay attention to the work surface. It should be massive enough so as not to sag under heavy workpieces, very smooth (so the part slides on the base without problems) and polished so as not to stain the workpiece.

When choosing equipment, it is important to remember the nominal number of revolutions. Many masters mistakenly believe that it should correspond to at least 1650 reciprocating movements of the file in 60 seconds - only with this indicator the cut will be perfectly even, without chips and notches. However, modern desktop machines from well-known manufacturers guarantee a perfect cutting line even at speeds of 700-1400 strokes per minute.

Do not forget about the maximum stroke of the saw blade - the thickness of the workpieces depends on this value. Additional options are also important:

- the presence of an engraver - add. shaft for particularly precise cuts and the manufacture of fine crafts;

- removal of wood dust and shavings from the work surface;

- illumination of the cutting zone.

How to navigate in models from different manufacturers?

On modern market there are many models of jigsaw machines, but there are several main "players", and each of them has its own characteristics, advantages and disadvantages.

Corvette models from Enkor are household class machines and for use in industrial environment are not suitable, but this is a fairly functional equipment, equipped with a swivel worktop to perform an oblique cut at the desired angle, a fixed stop with a degree scale.

Although the machines of this model are not designed for processing massive workpieces, the manufacturer offers a 150 W drive. The motor is a collector type, quite noisy and prone to overheating, unable to work without interruption and requiring regular replacement of brushes.

The amplitude of the saw stroke is 40 mm, the oscillation frequency is 700 in 60 seconds (in some modifications, a second speed is added - 1400 per minute to select the optimal mode when processing wood of different hardness). The files supplied with the equipment are not of impeccable quality, so it makes sense to immediately change them to analogues from a third-party manufacturer.

Household machines also include the Zubr models, which are compact enough even for use in a city apartment. The main feature of this equipment, which can be called its disadvantage, is a noticeable vibration, which interferes with the implementation of a high-precision cut.

Zubr machines are capable of processing plywood, solid wood, plastic, thin aluminum in a horizontal plane and at an angle. They also perform drilling, grinding and polishing; for this, an additional desktop and a flexible shaft with a chuck are provided in the delivery set.

Overheating of the cutting tool is prevented by the built-in cooling system, there is an electromagnetic switch to prevent accidental switching on. Files in Zubr machines are used special, reinforced, having pins at their ends.

The working surface is fenced off from the operator by a transparent casing to protect it from dust and chips, and the cutting area is cleared of sawing products by blowing to improve visibility. Efficient waste disposal is provided. The motor used is a collector type, sufficiently resistant to overloads. Its brushes are designed for long-term operation, but their quick replacement in the equipment is still provided.

For creative carpentry workshops RSW jigsaws are designed. Among their features are the minimum backlash and the most accurate trajectory of the cutting tool. The equipment provides everything for the efficient work of the operator: fencing and lighting working area, the ability to remove sawn products with a conventional vacuum cleaner.

In RSW machines, the file has an unusual arrangement - with the teeth down, pin files are used, they are replaced without a key. Also among the features of the equipment is the presence of the most powerful engine in the category of similar professional machine tools.

For craft workshops, art studios and serious hobbies, JSS jigsaws from the JET brand are designed. They provide a stable cutting angle, the speed of the cutting tool is changed steplessly by the built-in electronic system.

The manufacturer offers its own branded pin-mounted files, but JSS JET equipment is also able to work with “ordinary” ones. These machines are suitable for sawing complex shapes, but the workpieces to be processed should not be unnecessarily large. Their material is wood, chipboard, plywood, fiberboard, hard and soft plastics.

The blade tension lever is located in the upper part of the machine, which increases the convenience of working with it, and the cutting blade is installed in two versions - across and along the longitudinal axis of the equipment. Dust and sawdust are easily removed by an adjustable nozzle connected to the dust extraction system. The working table can be installed at an angle, to control the accuracy of its location there is a transport scale and a stopper.

How to build a jigsaw machine on your own?

Such equipment can be made at home with your own hands, craftsmen even create such machines from old sewing machines. If you have certain skills, the drawing and design scheme are developed independently.

As a table, you can use a countertop, a workbench, and if they are not there - homemade design from laminated plywood with a minimum thickness of 10 mm. A kind of table should be built from it with a working surface size of about 500x500 mm and a leg height of about 400-500 mm. They can be two or three solid or four separate. In the first case, the design resembles a box, in the second - a traditional table on a reduced scale).

The necessary parts are cut with a hacksaw or a circular saw into a single system individual elements fastened with screws. In the table lid, drill holes for fastening the tool and for the saw blade with a drill. In the sole of the jigsaw, you will also have to make mounting holes. After that, you can attach it with bolts to the tabletop so that the cutting part is brought out vertically upwards.

The advantage of such a home-made jigsaw machine is a clear fixation of the tool and a guarantee that the master's hand will lead the cut along the desired path.

A similar version of the machine does not always form the correct curvilinear cut - the file can deviate, especially if a massive workpiece is processed. The problem is solved by rigid fixation of the cutting tool with a pair of rollers that need to be placed on an additional part.

It is made from bars with a cross section of about 50x50 mm. which are connected into an L-shaped element using a furniture corner and self-tapping screws, attached to the desktop, and at the free end a bent metal plate with rollers made of bolts and bearing parts is placed with rigid fixation.

What to do if curly and very precise cuts are needed?

To perform the most accurate, very thin curly cuts, homemade jigsaw machine must be equipped with a cutting blade tensioning system. Features of this device include:

- the fork should be used very thin - for manual jigsaws;

- the rod of the electric tool must be connected to the clamp that tensions the saw blade using a special adapter;

- as a tension block, use the clamp of a conventional manual jigsaw.

In constructive terms, the machine differs little from that described above. It is necessary to build a work table with a hole for the cutting tool and attach a clamp to the table top, and place the electric drive from below.

If cuts are needed especially precise and thin, which implies extremely delicate and slow work, it is necessary to reduce the force on the files while ensuring strong tension and precise movement. To this end, a home-made machine must be equipped with spacers on long arms instead of the traditional clamp of a manual jigsaw.

The spacer structure and shoulders holding the file are made of wood or steel. Otherwise, the design of the machine resembles a model with a manual clamp.

Recently, I have been very interested in cutting out with a jigsaw, I don’t even know why it would be. It all started with the fact that I needed to cut a few gears out of plywood...

And off we go. At first I sawed the gears by hand, then I thought, pumping a muscle with a manual jigsaw is certainly good, but if you automate the process, it will be much faster!

So, for starters, get acquainted, this is a manual jigsaw for artistic sawing.

(all photos in this article were found on the Internet)

To cut, you need files, they are thin like wire, with sharp teeth. Previously, such files were sold in a pack of 50 pieces. Recently I went to the store, so these "bimesmen" began to sell them individually. During the evening, you can break a couple of pieces of such files.

For sawing, we also need a special table, it can be a board with a conical slot, screwed to the table with screws or a clamp.

For the convenience of attaching files to the machine, it is better to use special device, which will compress the contour of the jigsaw, so you can easily change the file without effort. With the help of a wooden eccentric, compression occurs.

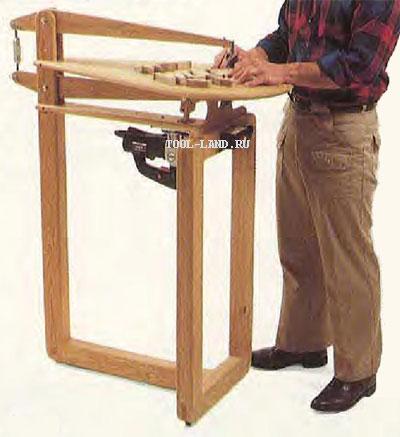

And now about automation. In the next photo you see a factory-type desktop jigsaw; on the Internet you can find a sea of various modifications. This thing is not very expensive, but even if I really want it in my city, I can’t find it, and in principle, there’s nothing to it.

Industrial machines are certainly good, but I will probably use them for a couple of months and abandon this occupation, and in general, such a machine, as I found out, can be easily assembled by myself from plywood and wooden blocks.

The next photo uses an industrial manual jigsaw and a spring to return the file.

So, we can easily assemble a desktop jigsaw with our own hands at home. I personally did this, but I have a special design, there are no photos of me in this article, but I will definitely post it, as well as a video in work.

An electric jigsaw is an extremely useful tool, without which it is simply impossible to imagine many operations for processing wood and materials based on it today. Possessing a relatively small mass and compactness, a manual jigsaw allows you to cut out products of a rather complex configuration from workpieces, but still, sometimes it would be more convenient to use a stationary tool. It is often more convenient to work with them, in addition, the machine provides a more accurate cut. True, such a machine costs several times more than a manual jigsaw. Those who do not want to spend extra money on this equipment can make a jigsaw table with their own hands and get an inexpensive and efficient hybrid as a result. hand tool and machine.

Figure 1. Diagram of a table for a jigsaw.

The simplest device

Some kind of table for a jigsaw can be made in a few minutes. The advantage of this design lies in its simplicity. It is easily mounted on a workbench or countertop and can be easily disassembled if necessary. The disadvantage is its small area.

The working surface of the machine will be laminated plywood, in which holes are drilled for sawing and for installing fasteners. The plywood thickness must not be less than 10 mm. You may also need to prepare holes for the fastening screws in the sole of the power tool. The structure is attached to the workbench with clamps. The heads of the fixing screws must be flush with the plane of the sheet. Such a machine can easily cope with cutting small workpieces up to 30 mm thick. What the device looks like is shown in Figure No. 1.

Back to index

Second option

Another stationary woodworking fixture has more parts, but it's also easy to make. The bed of a table consists of 2 sidewalls and a back wall made of a chipboard. The machine does not have a front wall so that it is easy to get to the button. Holes are drilled in the back wall for the cord and tube of the vacuum cleaner. The cover of the machine is made of laminated 10 mm plywood. The whole structure is pulled together by confirmations. The jigsaw is attached in the same way as in the first case.

Figure 2. Scheme of the frame-stop for a jigsaw.

On a home-made machine, you can cut larger workpieces, however, when working with thick wood, the jigsaw saw blade can deviate back and in both directions. This degrades the cutting accuracy. The disadvantage is eliminated by installing a stop bracket on a home-made machine (Figure No. 2). The jigsaw blade will move between 2 x 11mm bearings that are screwed to the L-shaped steel strip. The back side of the file will rest on the wall of the bracket. This design will not allow the working blade of the jigsaw to deviate from a given plane.

The bracket is attached to a frame made of birch bars 50 x 50 mm. It can be raised or lowered depending on the thickness of the material being processed and the length of the file. To do this, the frame with an emphasis is not attached to the sidewall of the machine tightly, but is pressed against it with a steel, hardboard or textolite plate. The vertical stand of the birch frame is located between the bed and the hardboard, into which 4 clamping bolts are inserted.

The area of the countertop depends on the size of the workpieces you are going to work with.

The machine can be made more perfect by installing a limit bar on it, which will help cut wood into blanks of the same thickness.

The limiter can be attached to the machine with clamps. It is made of wood, steel or aluminum corner. If desired, the bar can be installed on a sled attached to the bottom or sides of the table top. You can make 2 parallel slots in the countertop, along which the rail will move. Holes are drilled in it. Studs or screws with wing nuts are passed through them and slots. Roulette tapes are attached to the ends of the tabletop.

Back to index

Table made of bars and chipboard

Figure 3. Diagram of a table top for a jigsaw.

The manufacture of this table requires certain carpentry skills, since the connection of its tsarg with legs is carried out in a tenon-groove. However, dowels, wood glue and self-tapping screws can be used instead. The cover of the machine will be liftable to provide easier access to the tool when dismantling it. Figure 3 shows what the table top looks like. If desired, it can provide a place for installing a manual milling machine, then the machine will become multifunctional.

The table is made from:

- bars 80 x 80 mm;

- bars 40 x 80 mm;

- Chipboard or laminated plywood 900 x 900 mm.

The distance between the legs can be from 600 to 700 mm. Bars for drawers and prolegs are obtained after longitudinal sawing of 80 x 80 bars. You can choose the height of the legs yourself, based on how convenient it will be to work on the machine. At each end of the tsarg and prolegs, 2 holes for dowels are drilled. Corresponding holes are made on the sidewalls of the legs. Dowels are coated with glue for half the length and inserted into the ends. After that, the frame is going to draft. After correcting possible shortcomings, it is pulled together completely. All contact surfaces before assembly are lubricated with glue. Additional structural strength will be given by self-tapping screws, which are screwed through holes prepared in advance for them.

The lid is attached to one of the drawers on the hinges, for this a slot is made in it to facilitate the installation and removal of the jigsaw. 2 strips with a selected quarter are screwed to the back of the tabletop, which will include the sole of the power tool. Holes are made in the slats into which clamping screws or bolts will be installed. A jigsaw fixed under the tabletop will be able to process thicker workpieces if a recess is made for its sole in the lid. The easiest way to make it is with a milling machine. The table turned out to be quite spacious, so a large thickness of plywood or chipboard can provide sufficient strength for its cover. Use 20mm or thicker sheets.

For figured wood cutting, a hand-held jigsaw was traditionally used - a simple tool with a thin file that allows you to create elegant patterns from wood. Later, a jigsaw was invented, working on muscle traction like a foot sewing machine or potter's wheel.

The development of technology and the emergence of compact electric motors of low power led to the creation of a manual electric jigsaw, and then the corresponding electrified machine, which you can make yourself.

Purpose

Stationary units that ensure the movement of the saw blade vertically allow you to cut out sheet materials details of complex shape, elements with curved edges. If you insert a file into a through hole drilled in the workpiece, you can make a curly contour inside the product.

With the help of jigsaw machines, workpieces from various sheet materials are processed, including:

- solid wood;

- plywood;

- wood-based boards (chipboard, fiberboard, MDF);

- aluminum;

- plastic.

With the help of a jigsaw machine, it will be possible to increase labor productivity and significantly improve the quality of processing curly edges of products. This is due to the fact that a working person has both hands free and he can position the workpiece as accurately as possible relative to the moving cutting blade. This is the main advantage of a stationary tool with an electric drive from a manual jigsaw.

Jigsaw machines are installed in school and home workshops, also this species equipment is used in furniture production and in the manufacture of musical instruments. Modern laser machines can be used instead of jigsaws, as they provide the highest cutting accuracy along a given contour, but their use limits the effect of burnt ends of parts.

Device

The desktop jigsaw machine consists of the following elements:

- frame (support structure on which all mechanisms and components are mounted);

- Desktop;

- electric drive;

- crank mechanism (responsible for converting the rotation of the motor shaft into the reciprocating movement of the file);

- double rocker (equipped with clamps for files and a tensioning mechanism).

The machines produced today are mostly designed for the use of files with a length of 200-350 mm and a working stroke of 30-50 mm. Files differ in width (2-10 mm), thickness (0.6-1.25 mm) and type of shanks - they come with pins and without pins. The latter are more convenient, since in order to cut the inner contour, it is necessary to drill a hole in the workpiece through which the end of the file must pass. If there is a pin, the hole should be noticeably larger. Some models of jigsaws allow you to mount files of both types, including the old model, from a Soviet hand tool. Files also differ in the size of the teeth and their arrangement - it can be straight or spiral.

Tool selection

To choose a good machine suitable for solving specific tasks, you need to pay attention to its power. The main part of the models is equipped with an electric drive with a power of 90 to 500 watts. For home use, the optimal power is 150-200 watts.

An important selection criterion is the presence of two speeds of the unit. IN standard version- 600 and 1000 rpm. This makes it possible to select the appropriate mode for working with materials of various densities.

The desktop is fixed and swivel. Fixing the table at an inclination allows cutting material at specified angles other than 90°. There are also models that provide table height adjustment - this allows you to extend the service life of the file, since you can use its different sections along the entire length, and not just the central part, for work.

Manufacturers equip jigsaws with a variety of options, including:

- a compressor for removing chips from the marking line with an air jet;

- drilling unit;

- illumination of the working area;

- blade fencing (will not allow fingers to contact with a moving file);

- clamping device (prevents vibration of thin sheet material).

Additional options increase the cost of the jigsaw, but do not fundamentally affect its functionality.

Manufacturers

On the power tool market, there are different kinds jigsaws: from devices designed for creative work at home to high-performance models designed for professional use. In addition to machines that use conventional files, you can find band saws on sale.

The list of popular brands includes Bosch, Negner, Einhell, Proxxon, Makita, DeWALT, JET, Xendoll, Excalibur, Kroton, Korvet, Zubr.

The leader in quality and reliability is the products of well-known German brands Bosch, Einhell and Hegner. In addition, the lines of jigsaws include a wide range of models of various capacities and configurations, which makes it possible to choose a high-quality electric jigsaw for the home, which is optimal in terms of functionality.

Budget models, including those made in China, have also proven themselves well. Models of the brand Korvet, Zubr and others are suitable for home use without increased loads.

Before buying a jigsaw machine, regardless of its brand, it is imperative to conduct tests to assess the smoothness of the working body and the noise level, make sure that there is no extraneous sounds and vibrations. It is recommended to compare several models of different brands and purchase the option with the best performance.

Making a jigsaw with your own hands

Homemade machine, made to replace a conventional wood jigsaw, is able to provide high-quality performance of the main set of operations on curly cutting sheet materials. Depending on the purpose, it is possible to design a compact electric model or a stationary unit designed for high loads.

materials

As a basic scheme, it is most convenient to use a drawing of a simple wooden jigsaw with a flywheel and a pedal assembly and replace the mechanical drive with an electric one. If the machine is intended to be used only occasionally, a special electric motor can be dispensed with. Instead, connect any suitable power tool. It is convenient to use a screwdriver with adjustable speed.

The material for the manufacture of the machine itself is wood, while:

- the bed and the supporting pedestal for the lever bar are best made of high-strength plywood (minimum thickness - 18 mm);

- for a lever construction, it is necessary to take dense wood that is not prone to cracking under load - this is beech or oak (instead of buying bars, you can use straight legs of old chairs that are suitable in size);

- for the crank mechanism, plywood 10-12 mm thick is required;

- for the rest of the structural elements, pine lumber, various trimmings are suitable.

According to the scheme of the jigsaw machine, a bed and a supporting pedestal are made. Wood screws should be used as fasteners; it is recommended to coat the joints of wooden structural elements with PVA emulsion. It is important that the design is strong and there is no play, otherwise the accuracy of the machine will be low.

Part preparation and assembly

Next, the levers of the desired length are cut out, cuts are made at their ends for fastening the file. The mount is made of a steel plate 2-3 mm thick, with a pair of holes. The upper hole allows you to fix the plate on the lever, and the lower one is designed to attach the saw shank. Fasteners - screws of suitable diameter and nuts - it is more convenient to use wing-type. Mounting on the lower arm is installed in the same way.

At the next stage, the lever system is mounted on the frame. To connect the free ends of the levers, a screw tie (lanyard) is used, which makes it possible to easily adjust the tension of the saw blade.

Note! The length of the files used should be determined in advance, since the size of the lever mechanism depends on this. It is necessary to ensure the maximum possible parallelism of the levers relative to each other.

Racks need to be fastened together to create a solid support for the flywheel. The axis can be a stud or a bolt of at least 8 strength class. The flywheel with the lower lever is fastened by means of a connecting rod made of the same plywood, while the rods connecting to the lever must be metal.

At the next stage, a desktop with a swivel mechanism is made - a swivel arc with a slot must be cut out of plywood. The table is placed on the bed. To easily fix the swivel mechanism in the desired position, use a wing nut.

In this model, a screwdriver serves as an electric drive - for work it is enough to connect its cartridge with the flywheel axis. You can adjust the speed using a clamp with variable force, made of a strong strap and a small clamp (or other screw tightening).

Simple in design, a homemade machine is easy to use.

Rugged fixed construction

The design of a jigsaw for professional use is practically the same as a compact wooden model. It is only important to choose the right materials so that the unit is able to withstand increased loads and does not vibrate during operation.

- bed - heavy chipboard;

- rack for lever construction - hardboard, textolite of suitable thickness;

- levers - steel square pipe;

- countertop - any durable, hard and smooth material.

Elements for fastening the blade (you can take it from an old hacksaw) are soldered to the levers or fixed with screws.

You will need a serviceable electric drive with a gearbox that will provide the necessary torque. To start the engine of a homemade jigsaw, it is convenient to provide a foot pedal (taken from an old electric sewing machine or fabricated using any suitable electrical button).

When assembling the structure, metal racks and metal fasteners are used. With the help of a metal insert, you can strengthen the fastening of the connecting rod. This will reduce vibration and reduce wear.

The tabletop has a long working slot for the possibility of rotation around the longitudinal axis.

A spring is provided to tension the web. The lower lever is responsible for the movement of the working blade, the upper one helps to keep the file in a vertical position.

Thus, an electric jigsaw can be assembled on its own using scrap materials. This will not require serious financial costs, but will only take some time to search for materials, necessary details and assembly.

Since childhood, we have been familiar with the technology of sawing with a jigsaw. The principle is simple - a fixed part is placed on a stand with a technological cutout, the cut is made by moving the file. The quality of work depends on the firmness of the hands and the skill of the worker.

In this way, you can literally cut lace from thin wooden or plastic blanks. However, the process is laborious and slow. Therefore, many masters thought about small mechanization.

A simple design from the last century

Even in the magazine "Young Technician" drawings were offered on how to make a jigsaw machine with your own hands. Moreover, the design does not imply an electric drive, the drive works from muscular strength, like knife grinders.

The machine consists of the main parts:

- bed (A)

- desktop (B) with a slot for the canvas

- lever system (B) for holding the saw blade

- flywheel (D), which is the primary drive pulley

- crank mechanism (D), combined with the secondary drive pulley, and driving the levers (B)

- pedal assembly (E) with a crank mechanism that drives the flywheel (D)

- saw blade tensioner (W)

With the foot of the foot, the master sets the flywheel (D) in motion. With the help of a belt drive, the crank mechanism (D), connected to the lower lever (B), rotates. A file is stretched between the levers, the degree of tension is regulated by a lanyard (G).

With a well-balanced flywheel, a sufficient smoothness of the saw blade is ensured, and such a home-made jigsaw machine allows you to massively cut out the same type of workpiece, saving time and effort. In those days, jigsaw saw blades were produced in the form of a flat tape with unidirectional action.

Therefore, to obtain patterns of complex shape, it was necessary to rotate the workpiece around the canvas. The dimensions of the workpiece are limited by the length of the levers (B).

From mechanical jigsaw to electric one step

The foot drive cannot give real freedom of action and uniformity of the sawing stroke. It is more reasonable to adapt an electric motor for a crank mechanism. However, if you use a desktop jigsaw from time to time, it makes no sense to make a stationary structure with its own motor.

You can use household power tools. For example - a screwdriver with a speed controller.

Materials are used, literally from wooden scraps and old trash. The only critical part is the frame. It is better to make it from durable plywood with a thickness of at least 18 mm.

We make all connections on wood screws, the joints can be smeared with PVA glue. We assemble a support pedestal for the lever rod from the same material. The design of the support should not have backlashes; the subsequent accuracy of the operation of the entire machine depends on its strength.