Wooden vase from a flat board. Detailed photo report. Decorative vases for the interior - crafts from wood cuts How to make a hole in a vase from wood

Vases can be a wonderful interior decoration. You can even create some of them yourself. It is possible to decorate and transform vases very quickly, even with your own hands. This will allow creating more and more new distinctive features in the interior.

1. Original filling of the vase

A great option to fill a vase with wine corks, with which the vase is immediately transformed.

2. Lemon vase

A simple, but at the same time very striking option for decorating a vase with lemon decor, which will be just a godsend.

3. Small bottle vases

A beautiful option to create many mini-vases with your own hands from ordinary bottles.

4. The vase is decorated with beads

It is possible to transform and decorate a vase using beads, which will create a truly beautiful vase in a minimum of time and money.

5. Wooden decor vases

Nice design of the vase with branches, which will give lightness and unobtrusiveness in the interior of any of the rooms.

6. Stylish and simple vases

Beautiful design of small vases that will decorate any home.

7. Vases are decorated with cord

With the help of a thread or cord, it is possible to create unforgettable vases, which will simply be an excellent solution for decor.

8. Making a regular bottle

An excellent option to arrange an ordinary bottle in the form of a beautiful vase, which will definitely please.

9. Transformation of bottles

A cute solution to create from ordinary bottles beautiful vasesthat will be a godsend.

10. Decoration of vases with sparkles

An original solution for decorating vases with gold sparkles.

11. Cute shiny vase

A great option to create an original and cute shiny vase that will decorate any interior.

12. Vase is decorated under a candlestick

One of the fastest and simple options, so this is the creation of a candlestick from a vase.

13. The perfect combination

If you combine several bottles the same shape, then it is possible to get just such a non-standard vase with cells.

14. Vase of tree branches

Cute and very interesting option create a vase of tree twigs that will transform the interior of any room.

15. Bright painting of a bottle decorated with a vase

An excellent and very interesting option for painting a bottle, which became a vase very quickly and easily.

16. Original strapped bottles

Decorating bottles is a very interesting and difficult moment that should be taken into account and used to the maximum in practice.

17. Decorating a vase with pencils

An original option to decorate a vase using ordinary colored pencils, which will be a godsend for any interior.

18. Decorating bottles with thread

It's a nice idea to decorate ordinary bottles with a thread, which will be just a discovery and allow you to create original vases.

19. Decoration of an ordinary transparent vase

Fast and simple decor of an ordinary vase, which will transform the interior in the shortest possible time.

20. Painting wine bottles

Decorating wine bottles by hand painting can be even more attractive than that.

21. Vase decor with wood

The original design of a flower vase using wood, which looks charming and delicate.

22. Non-standard wire vases

Beautiful and perhaps very original version create a wire vase that looks very interesting.

23. Excellent table decor

One of the best and simplest options for decorating a table with a cute vase that you will like.

24. Cute DIY vases

With your own hands, it is possible to decorate any of the vases in a wide variety of ways, which will definitely please and inspire.

25. Successful vase decor

A nice solution to ennoble an ordinary transparent vase with burlap and accessories.

26. New Year's vases

Interesting decor of vases in New Year's style, which will simply be a highlight of any interior.

27. Original vase with a transparent bottom

A nice and very interesting example of the design of a vase with a transparent bottom, which will become a feature of the interior.

5 674

How to make a vase from wood. Wood vases are usually round and made from a solid piece, with turning turning 75 percent of the wood into shavings. At the exit, we get one vase and a huge pile of shavings, but vases are not made of poplar - they are made of valuable species of wood, although poplar has been growing for more than one year. Our method of making a vase from wood will be different. Soon it will become clear to you how to make a vase from wood, with great savings in wood.

We will need:

- Glued board of three types of wood (17 * 20 * 3 cm), or bars of three types of wood, different shades.

- Drill.

- Drill for wood.

- Grinding attachments.

- Clamps ..

- Wood glue.

- Shellac (a substance widely used in woodworking).

- Muslin (cotton fabric), tassel.

Tape machine for cutting wood.

The entire wood vase can be formed from one glued blank board. This allows us to make the angle at which the rings of our future vase are cut. And the effect is as if the vase was made from a single piece.

First, we need a glued board made of various types of wood (walnut, mahogany, maple).

The gluing, along the long side, goes in this order walnut, mahogany, maple, then mahogany, walnut. We attach the template to the center line of the glue strip and apply the markings. Precisely, the alignment of the central strip will allow you to achieve the effect of a solid blank.

We cut out the workpiece along the outer contour of the first ring, for this (sadly) you will need tape machine for cutting wood.

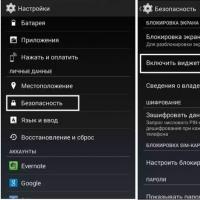

Thereafter. At the intersection of the center line of the workpiece and the inner oval of the marking, you need to drill a hole at an angle of 25 degrees in order to refuel the saw.

To drill at an angle, you need to cut out an auxiliary template - cut off one edge of a hardwood block of wood at this angle. Write the angle values \u200b\u200bon the bar (we will need several with different angles).

Then we cut out the core of the workpiece along the contour, set the table angle to 25 degrees. We attach the ring to the rest of the board, aligning the central stripes, trace along the inner edge, create a cutting line for the second ring. Then we repeat the cutting procedure only, we take the hole angle 28 degrees. With the help of the second ring, we make the third, adhering to the above instructions. As a result, we get three rings and the bottom of our vase made of wood.

We glue three rings together. We first check whether they fit tightly to each other (you can combine the rings and shine a flashlight inside). The adjustment of irregularities, if any, is done with sandpaper, and again we check.

We smear the rings with glue, combine them so that the central line appears to be solid. We clamp into clamps using two boards.

Our glue is dry, it's time to sand.

We grind with various attachments, gradually reducing the grain size, to obtain a smooth surface. After sanding, glue the bottom, try to prevent the glue from protruding, if it comes out, after five minutes, gently unclench the clamps, wipe the glue with a dampened cloth, and clamp back until completely dry. Next, we grind the vase together with the bottom.

The final operation is to apply several layers of shellac and shine with a piece of muslin.

How to make a vase out of wood is now clear - but it is not very easy to implement the plan, as it turned out.

Wooden vases look very nice. Usually done on lathe... But 90% of the wood turns into shavings.

There is a technology that allows you to make a vase from a flat panel.

Here's what happens:

I chose the material for the sample for a long time. On the one hand, you want something interesting, on the other, so that you don't mind spoiling it.

In the end, I settled on a nut, with oak and wenge inserts.

Walnut board 75mm wide and 15mm thick cut into 3 pieces.

4mm oak veneer must be cut into 15mm dies.

How to do it if not circular sawbut have a pair of clamps and a scoring saw?

Like this - the pistol is clamped between the nut dies ...

And sawed.

As a result, you get an even plate of the required thickness:

I glue the walnut into a shield with spacers - two oak dies, between them a thin wenge veneer. (which was sawed using the same technology)

Saw scratches visible. Slight sloppiness, plus hard oak, which sawed along the grain.

It's not scary, all the same, the shield will have to be sanded to level out the gluing errors.

And again I glue it with spacers, leave it overnight:

I level the shield with a belt sander, remove the remaining glue. Probably it was worth making the wenge continuous:

The result is a 14 mm thick shield. It took 0.5 mm from each side.

Based on the shield and the desired dimensions of the vase, the angle and step are selected:

I print the drawing, with the help of an awl I combine the centers of the shield and the drawing, I glue the drawing:

I saw a small staff at an angle of 38 degrees:

I fix the shield with clamps on the jigsaw table and using the rail as a guide, I drill 2mm holes with a drill at an angle of 38 degrees:

I thread a file into the hole:

And let's go!

Cut through the first ring:

And here it is - the bottom!

The wood is very hard, sawing slowly, if you squeeze it a little, the saw will burst. To replace the file, you need to return the table to a horizontal position, untwist the saw attachments, thread the shield, adjust it again to 38 degrees, adjust the tension ... Moreover, the file almost always breaks when 3 cm remains before the end of the ring.

The second ring, the picture begins to emerge.

Bottom view:

And after the fourth ring the files ran out. I used up one and a half packs. No more, I put it off until tomorrow.

I drove into a store, bought 8 packs of files (to be sure it was enough), sawed:

Slide the ring:

Sleight of hand and no fraud, the rings fold into a vase:

Can be combined with a shift. You can make inserts between layers. There are a lot of options.

I begin to glue, while without a bottom, so that it is more convenient to grind the inner surface:

Checking the alignment of layers:

I leave it under load overnight:

Result. The surface is rough, but the line alignment is not serious.

Darkening - marks from sawing with an ultra-thin file (41 teeth per inch), which was drowning in sawdust and the wood was burnt.

It is necessary to level the inner surface.

Attempt number one - a steel rod with sandpaper glued to double-sided tape.

Not an option, too flexible.

Attempt number two, grinding drum on the same spindle.

Also does not fit, the machine is light (as I intended it). Doesn't hold up, plus it's inconvenient to work.

Attempt number three. Sanding drum on a flexible arm.

The drum is small, sawdust fly to where it is least needed, but you can work:

For fine grinding, I collect 400 sandpaper petals:

But it doesn't grind. I continue with my hands.

It takes a long time, the surface is far from ideal.

I find an error - the penultimate ring is glued in with an offset of 180 degrees.

Well, it will be a reminder ... In the end, it could have been much worse. Let it add charm - it will be a border. The main thing is that the spacers are well aligned.

Most of all, sweat floods the eyes and falls on the vase.

The respirator was once snow white:

I glue the bottom. To speed up the process as a press, I use my weight with dumbbells in my hands ... The vase can withstand more than 100 kg without squeaking, despite its lightness and thin walls. Now I think, what would have happened if the vase had scattered?

The second important condition for the safe operation of a fine-grooved chisel is the requirement to always direct it down the slope, that is, to a smaller diameter. This tool is usually sharpened at 30 °. this operation is very convenient to carry out

using a special device that I made for sharpening deep-grooved chisels, slightly changing its setting. The chamfer is perfectly flat without edges. This device will be described later in another article, but now it should be clarified that instead of a finely grooved chisel, a deep grooved chisel with a less bursting character can be used to form the profile of a vase, which I often do.

Photo 6 shows the final scraping of the turned outer surface of the vase with the wings of a fine-grooved chisel, which is carried at 45 ° to the surface of the part. Final alignment of the workpiece with a longitudinal position wood fibers can be done with the help of a jamb chisel, as shown in photo 7. True, it has a very bursting character and even poses a danger, since when buried it can fly out of the hands and injure the turner. At the same time, in the hands of an experienced specialist, such a tool is universal, allowing you to grind almost everything, but only with a fractional arrangement of wood fibers, that is, with transverse turning, a gantry chisel is absolutely inapplicable. By the way, her blade is sharpened at 25 ° necessarily on the platform of the electric sharpener.

After completing the formation of the external profile of the vase and leveling its surface, as well as applying small decorative ribs and grooves with a fine-grooved chisel (photo #), I carry out wet grinding of the product with P220 grit sandpaper. for which I dip the "skin" into a bowl of water, and spray the surface with a sprayer. This resurfacing is preliminary. and in the future, after drying the product, final adjustment will be required. Next, I cut off the support protrusion on the bottom of the vase with a thin cutting chisel (photo 9) and clamp the bottom in a chuck with the support of the product with the tailstock (photo 10) for a snug fit of the front plane of the jaws to the bottom of the vase. The next step is to drill a deep hole in the neck of the vase, but since it has a great length, for reliability, I decided to additionally fix the neck in the lunette (photo 11), the use of which is a common practice when turning vases.

Steady rests for small lathes are not sold, they have to be made by yourself. My three-wheeled steady rest (there are also two- and four-wheeled devices) is made of 40 mm plywood. the workpiece hole diameter is 220 mm, and the roller skate wheels with precision bearings ensure a relatively quiet operation. As soon as I installed the steady rest, I had to interrupt my work: I had to take a roll of cling film and wrap it around the vase (photo 12), otherwise the product made of damp apple tree wood (an extremely “crackling” species) would have cracked during my absence. By the way, I also wrap semi-finished bowls made of weak, badly rotted wood with this film to prevent them from scattering into pieces when boring the inner cavity. The vase I conceived was to become universal, that is, suitable for both artificial and natural flowers. In the latter case, the water should be poured into a suitable small vessel, for example, a glass test tube 200 mm long and 20 mm in diameter, placed inside the vase (photo 13).

I didn’t have a suitable long drill (such as a Lewis spiral or a feather with flutes for chip evacuation) for making a hole in the neck of a vase. I had to fit a simple flat "perk" 22 mm wide from a set produced in Soviet times on a long (300 mm) steel rod 10 mm in diameter and clamp it in a powerful drill chuck with a Morse taper (photo 14). The very short base of my machine did not allow inserting the chuck into the pi-zero of the tailstock, and the thickness of the rod of the created device did not make it possible to fix it in the 10 mm chuck of a conventional drill (9 mm). As a result, when drilling a deep hole in the neck of a rotating vase, it was necessary to simply hold the cartridge in hand with great effort, resting the rod on the hand-hand. Photos 15 and 16 show the initial and final stages of this process. By the way, for convenience further use the tube inserted into the neck of the vase should protrude about 5 mm from there.

At the stage of finishing the bottom, i.e. removing the dents from the chuck jaws and leveling the end, it was necessary to unfold an almost finished vase on the machine. Previously, I carved a support faceplate with a recess for the diameter of the neck (photo 17). I placed it there and backed the bottom with a crown center, into which I inserted an additional homemade narrow nozzle. When I later grind other vases of approximately the same shape, I simply carefully clamped the neck into the chuck using small F-type jaws, placing a strip of plastic more than 1 mm thick under them. A piece of coaxial (antenna) cable will also work as a softening pad.

Photo 18 shows the search for the center at the bottom, when for some reason it was not planned or disappeared. The beating is marked with a black felt-tip pen, then you need to tap the mark with a mallet to shift the workpiece so that the desired center is in its place. After that, the bottom is processed using a deeply grooved or finely grooved chisel (photo 19)

After turning, the vase must be dried without cracking. Cracking is almost inevitable in air, which is aggravated by the large thickness of the vase in the lower part (the thinner the walls of the product, the higher the chance of avoiding cracks, as well as some warping). I dry my raw wood products in one of two ways: either I put them in a kraft paper bag filled with wet shavings of the same wood (photo 20), or I fill the product itself with these shavings, which I then wrap in two layers of newspaper and put on the shelf in shed. The latter method is especially convenient and effective for bowls and plates with walls 4-8 mm thick, which dry out in the summer without cracks or warpage in about two weeks.

Unfortunately, the formation of cracks in the lower thick part of the apple tree vase could not be avoided even after two months of drying in a craft bag, and circumstances did not allow it to dry longer. The cracks had to be repaired by gluing in thin sheets of the same material, sawn off with a band saw and then processed with a Proxhoop carbide grinder and a Black & Decker electric file. The inserts were almost invisible, but this extra work made me rethink the technique of turning vases in order to make their lower parts hollow to reduce the likelihood of cracking.

I must say that from the very beginning I was gnawed by doubts about the legitimacy of the simplified approach, limited to simple drilling of a narrow channel in the neck, which can be seen in a number of videos on the Internet. I used to grind cavities in the bottom of vases, but there were always various difficulties. True, I rarely made vases. Last summer I made a series of vases of a similar shape, and the problem had to be solved radically. From the very beginning, at both ends of the cylindrical workpiece, it is machined along the shoulder. Having formed the outer profile of the lower part of the vase, you should immediately start boring its cavity using a steady rest, holding the workpiece in the chuck by the protrusion in place of the neck. A hole with a diameter of about 50 mm is bored with the help of a deep or fine-grooved chisel. through which it will then be possible to introduce any of the curved chisels - articulated, with a carbide nozzle or a nozzle-cutter (photo 21), and the residual wall thickness is constantly monitored with a caliper.

At the end of the boring process, it is necessary to separately grind a plug of a suitable diameter from the same wood material and glue it into the hole of the protrusion (bottom). Here it is necessary to estimate the depth of the plug protrusion into the cavity in such a way that the test tube, which will further rest on it, protrudes outward by the aforementioned 5 mm. If the test tube falls into the neck, there will be an additional hassle with gluing a piece of wood to the bottom of the vase through a narrow channel.

The part of the glued-in plug that protrudes outward, I cut off with a band saw. Further, the bottom will be finally processed in the way already described above.

If the vase has a different shape with a much wider neck, then the

a tag will not work here as a vessel with water. What to do? The decision came pretty quickly when I took a semi-rotten birch souvel with a bright texture, prepared a couple of years ago in the forest, and carved a vase from it with a neck with a diameter of 35 mm. Further, in my stocks, I found a two-meter plastic tube of bright green color with a diameter of 32 mm and cut a piece about 160 mm long from it on a band saw, deciding to turn it into the required vessel. First, with the help of a gas microburner, I made sure that this plastic is not thermoplastic, that is, it will not be possible to weld the required container from it. I had to turn to gluing, first sawing off another small piece from the original tube and making an additional fractional cut on it. Using an industrial hair dryer, I heated the cut to a soft state. unfolded it into a plane, put it under the press, and after cooling the aligned piece of plastic with a compass, he applied the contour of the circle on it, which will play the role of the bottom in the vessel from the tube. Further, I quite accurately, albeit by eye, brought him

the size according to the inner diameter of the tube (28 mm) using a Black & Decker electric file (photo 22). I drove the circle into the tube to a depth of about 3-5 mm and filled it on the outside with a thick layer of a fairly universal waterproof superglue "Master" based on vinyl acetate copolymers, which I have kept for ten years (photo 23). The bright color of the vessel seemed vulgar to me, and I painted it with brown quick-drying nitrocellulose enamel. Subsequent exposure to water for a month showed the tightness of the manufactured vessel, and the general aesthetic properties of a chiseled vase with a living goldenrod branch can be assessed in Photo 24.

Finally, I would like to note that the stores sell a wide variety of plastic water pipes, from which you can easily make any vessels for fresh flowers and place inside chiseled wooden vases... Photo 25 shows a number of such products, created by me last summer from various types of wood using the method described above.

DIY wooden vase - photo

Photo 1. Transverse sawing of a log on a trestle. Photo 2. Sharpening a roughing chisel on an electric grinder. Photo 3. Rough processing of the blank with a roughing chisel. Photo 4. Formation of a protrusion at the end of the cylinder for the chuck using a cut-off chisel. Photo 5. Formation of the outer profile of the vase using a fine-grooved chisel. Photo 6. Fine scraping of the surface with a fine-grooved chisel. Photo 7. Finishing the surface with a jamb. Photo 8. Application of decorative beads and grooves with a fine-grooved chisel. Photo 9. Trimming the support ledge with a thin cutting chisel.

Photo 10. Clamping the bottom of the vase in the chuck with the support of the tailstock. Photo 11. Fixing the neck of a vase in a homemade lunette. Photo 12. Sealing the vase cling film... Photo 13. Glass test tube. Photo 14. Homemade perk

Photo 15. Beginning of drilling a blind hole for a glass test tube.

Photo 16. Cork in the hole of the vase. Photo 17. Grinding a support plate with a hole for the neck of the vase. Photo 18. Reverse fixation of the vase and search for the center at the bottom. Photo 19. Additional processing of the bottom with a fine-grooved chisel.

If you have professional tool, you can master its capabilities endlessly. For example, an ordinary building lathe is often used as a basis for making souvenirs and various decorative items. A beautifully crafted wooden candlestick on a lathe looks great in classic interior houses. A large vase made of wood can amaze the imagination. Sometimes in the hands experienced master an ordinary chock at first glance turns into a real artistic masterpiece. How do they do it? What else can you carve yourself?

A wood lathe allows you to make not only building blanks, but also various decorative products that are designed to please the eye and demonstrate the capabilities of the equipment. Any wood crafts are very practical, they will always find a place in the house, so you can safely experiment and try to do something with your own hands. The easiest way is turning a vase made of wood; a jug, a salt shaker and a casket for storing all sorts of small things can easily turn out. You can suggest making chess.

Vase

How can you make a vase on a lathe? To make it, you may need a certain tool. In addition to the lathe, you need to take cutters, a planer, a hacksaw, a ruler, a compass, an ax and a saw, sanding skins and a chisel.

The vase turning process is extremely simple. True, it should be noted that vases are complex in configuration and simple. Let's consider how you can carve a simple option.

- First, a block is cut with a saw, 10-20 cm long.

- It is necessary to earn extra money with a plane, both from the ends and along the length.

- The workpiece is installed in the chuck of the machine.

- The machine is turned on and checked for runout of the part.

- If present, alignment is required.

- The top layer of wood is removed to a depth of 1 cm.

- The chamfer is removed at an angle of 45 ° from the outer end.

- A drill is inserted into the tailstock.

- A hole is drilled with a depth of 3-5 cm less than the length of the workpiece. That is, the bottom of the vase is determined.

- Now, with the help of a cutting, which is called a joint, the cavity of the product is cut out.

Since the vase can have a different shape: straight, oval, and so on, then, accordingly, the boring of the upper surface is maintained in an exact shape. After that, the product is polished from the outside and from the inside. What is sandpaper used for? The wooden product is removed from the machine, the bottom is finished manually using a planer and sandpaper. Then the souvenir is varnished.

Chess

Chess - figures are small, therefore their production requires a certain experience and firmness of the turner's hand, as well as his eye. To make a figure, you need a small block with a section of 50x50 or 60x60 mm. On the one hand, it is formed under a smaller section, for example, 40x40 or 30x30 mm, as shown in the video.

With this smaller end, the workpiece is inserted and clamped into the chuck. Now you need to cut the free end of the blank with a cutter and press it with the center of the tailstock. A layer of wood is removed with a cutter so that the workpiece becomes a round section. After that you can start making the chess piece itself. You can use traditional forms, you can dream up.

As soon as the figure is completely ready, it must be sanded, and at the end cut off from the pressed part of the workpiece. It remains only to manually varnish it or paint it black or white color... By the way, a wooden candlestick is made on a lathe in the same way. Its length is longer, which means that a longer workpiece will be needed.

Making a box

The box is not the most difficult element that can be turned on a lathe. But if it is a product with a lid, then the drawings will be required here. After all, the lid should go into the box and sit on the groove, that is, the lid should be flush with the edge of the product itself.

To make the box, you will need a cylindrical blank, which is installed in a lathe. The main thing is that the workpiece does not reach the bed.

- First, a layer of wood is removed with a semicircular cutter to give the workpiece a rounded shape.

- Then you need to work on the surface with a jamb, that is, make it smooth.

- After that, it is necessary to form the inner cavity of the wooden product. For this, a narrow, straight cutter is used. This operation cannot be completed in one pass, so it will have to be carried out stepwise.

- Using a triangular cutter, it is possible to expand the internal cavity to the wall thickness.

- The bottom of the box is leveled with a straight but wide chisel. It also makes a groove for the cover.

- Grinding of internal and external surfaces is carried out.

- Varnish is applied on top, wax from the inside.

The lid is made of the same material as the box itself. It just requires a thin workpiece, which is fixed in the chuck of a woodworking lathe. First, processing is carried out with a wide straight cutter, that is, the inner part is formed, it can be flat or concave inward. Grinding is mandatory.

Then the outer part is formed, for which the workpiece will have to be turned over. That is, the semi-finished part of the cover is cut off and the already almost finished inner side is installed in the cartridge. Then the outer side of the cover is formed with the same cutter. It can also be flat or convex. At the end, grinding is carried out. Then the finished product is varnished.

In principle, the order of production of the sides can be changed if the lid is equipped with a holder. To do this, you will have to take a thicker workpiece to sharpen the pen. It can be round, oval or curly. You can make a handle as a separately turned element and attach it to the box lid with an adhesive.

The diameter of the lid must match the diameter of the inner groove of the box That is, the cover should fit freely into the groove.

These are the products you can do with your own hands on a wood lathe. The most difficult of the decorative objects described above is the casket. Here it is necessary to adhere to the exact dimensions, especially the wall thickness. They made it a little thinner, and there will be a high probability that it will burst over time. In addition, you will have to precisely adhere to the diameters of the lid and the groove on the box itself. If one of the dimensions does not match, then either the lid will fall inside the box, or it will be on the edge of the product.

Therefore, when turning on a lathe homemade crafts attention and accuracy are required from wood (the work is not rough). Of course, it is imperative to take measurements with a caliper during the work process.