Original roofing and designer roofs: How to make a domed onion roof. Roof decor element - rafters for onions and poppies of the dome system head - drawings, diagrams, explanations and photos. How to make a domed greenhouse with your own hands

(20

estimates, average: 4,40

out of 5)

When deciding on a project for summer cottage construction, first of all, not only comfort is assessed, but also the appearance of the future building. A private house is considered to be a place for relaxation, so it should be made beautiful and comfortable. If you want to build a unique greenhouse, a house or a gazebo on your personal plot, then you should try to think about building a geodesic dome. It looks like a rather complex structure, but even a not very experienced builder is able to build it, and material costs will be small. This article will describe how to build a dome with your own hands.

When deciding on a project for summer cottage construction, first of all, not only comfort is assessed, but also the appearance of the future building. A private house is considered to be a place for relaxation, so it should be made beautiful and comfortable. If you want to build a unique greenhouse, a house or a gazebo on your personal plot, then you should try to think about building a geodesic dome. It looks like a rather complex structure, but even a not very experienced builder is able to build it, and material costs will be small. This article will describe how to build a dome with your own hands.

Defining a Geodesic Dome

Experts believe that most people have no idea about such a building structure, because it is very rare. That is why it is worth describing in detail all the features and technical characteristics of the geodesic dome... Structures with a load-bearing mesh shell were developed by the inventor Richard Fuller. First, he took a very strong sphere-shaped structure and divided it into small triangles, whose sides are located on regular geodetic lines. Richard Fuller's calculations were able to make the construction of the dome simple and accessible to anyone.

Experts believe that most people have no idea about such a building structure, because it is very rare. That is why it is worth describing in detail all the features and technical characteristics of the geodesic dome... Structures with a load-bearing mesh shell were developed by the inventor Richard Fuller. First, he took a very strong sphere-shaped structure and divided it into small triangles, whose sides are located on regular geodetic lines. Richard Fuller's calculations were able to make the construction of the dome simple and accessible to anyone.

The inventor believed that such a unique structure of the building was obliged to solve the problem of quickly building a cheap and comfortable home. This development was not appreciated by specialists, and it not used in mass construction... However, for the construction of a unique cafe or a beautiful summer house, Fuller's geodesic dome is the best option.

Richard Fuller's design is a fairly robust design. The geodesic dome evenly distributes the entire mass, can withstand huge loads and reduces financial investment in the construction of the foundation. The unique spherical shape is able to withstand the most powerful gusts of wind. The savings in the construction of such houses are due to a reduction in the total lateral surface area. In the dome itself, round walls help high-quality air circulation, creating a comfortable microclimate.

The main disadvantage can be considered very complex, compared to simple houses, mathematical calculations. Since the construction consists of a huge number of parts, then it is necessary to insulate quite a few joints. The geodesic dome has no other significant drawbacks.

Measurements and calculations

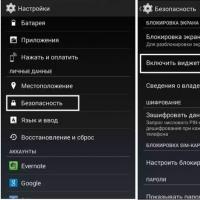

If you want to build a geo-dome with your own hands, you first need to carry out all the mathematical calculations. The main task of calculating a geodesic dome is to have a certain radius, get data like this:

It is necessary to focus on such a node for building a geo-dome as a special connector. This part is a knot that connects all the rafter parts. Since the connector is the main element for securing the entire structure, it is made of high quality durable material.

Depending on the design of the geodesic dome and the location in it, the connecting connector must have a different number of petals. All fasteners for building a domed house can be purchased or made by hand. A good example would be the connector from regular perforated tape... Such a connector has a very valuable quality, because the angle of inclination is quite simply adjustable on it. Small diameter geodesic domes can be constructed using the connectorless method. However, when building a large house, it is necessary to use a metal connector to fasten the ribs.

In order to make calculations, you need to know the dimensions of the structure. It must be remembered that the total area of \u200b\u200bthe manufactured geodesic dome will be slightly less than the area of \u200b\u200bthe circle, because at the base there is a polyhedron that is inscribed in a circle. The height of the building can be determined by the total length of the diameter. It is worth noting that the higher the height of the dome, the more the structure will look like a sphere.

To calculate the necessary details of the future design, it is worth using a special online calculator. You need to enter data about the height and radius of the building, and the calculator will calculate the geo dome and provide the length and number of edges, the type and number of connectors.

DIY construction

The most suitable structures for dome construction are small greenhouses, cozy gazebos or country houses. First you need to choose a place to build. If this is a greenhouse, then you need to find a well-lit area. Suitable for a house or gazebo slightly shaded area... The plot for any of these buildings is leveled, and then all the debris and tree roots are removed from it.

The most suitable structures for dome construction are small greenhouses, cozy gazebos or country houses. First you need to choose a place to build. If this is a greenhouse, then you need to find a well-lit area. Suitable for a house or gazebo slightly shaded area... The plot for any of these buildings is leveled, and then all the debris and tree roots are removed from it.

Greenhouse

The easiest way to build a domed greenhouse. To assemble it, you do not need a foundation, and the base material can be ordinary boards, bars or metal pipes. On a previously prepared surface, it is necessary to start assembling the base of the greenhouse-dome. First of all, triangles are collected and fastened together. In order not to confuse the faces, they must be signed and checked against the drawing. If the greenhouse is small, then during assembly, the connecting connector should be replaced with a simple mounting tape and fastening materials.

The made geodesic dome should be covered with a simple film. A domed greenhouse will look much better, which covered with polycarbonate sheets... The triangles cut out of polycarbonate must be fixed to the frame, and all joints must be closed with decorative slats. From the street, geo-domes can be decorated with decorative stone, flowers can be planted and a small fence can be installed. Such a domed greenhouse will be a unique decoration for any country house.

Alcove

In the form of a geodesic dome, you can build a gazebo. This requires adhere to these recommendations:

After the manufacture of the structure of the domed gazebo, an equally important stage of work follows. It consists in covering a round arbor with a dome. The material for this can be used in a variety of ways. If the structure of the geodesic dome is not completely covered, and a couple of sections of the gazebo are left open, then they can be decorated with a beautiful fabric. In such a comfortable gazebo, you can enjoy spending your free time with family and friends.

House

The dome can become the basis of a unique house in a summer cottage. The main difference from the gazebo and greenhouse is the need to build a foundation. In order to build a domed house, it is worth adhere to the following recommendations:

- a well-insulated foundation is needed;

- special corner posts are attached to the base of the foundation, which are reinforced with horizontal struts;

- the construction of a domed house is being assembled;

- outside the house must be sheathed with plywood sheets.

Having installed the door and window frames, you should start finishing the geodesic house from the inside. Good insulation is laid in all openings, which is sewn up with plywood sheets. In order to build a domed house, you need no more than three months of work. The shape of the geodesic dome will help save on the amount of materials.

When living in such a house, you can appreciate the main advantages of this design.

When living in such a house, you can appreciate the main advantages of this design.

Round views of the rafter system will be incomplete if you do not stop at the "onion" roof. This shape of the roof of buildings is a distinctive feature of Orthodox churches and temples. It is difficult to imagine that someone would want to use this form of roofing for their own houses. But if we take into account the fact that today not all churches are being restored by construction firms, especially in distant villages, then additional knowledge of the correct construction of the "onion" roof truss system will not be superfluous.

If the dome has a diameter of no more than 3 m, then a wooden frame can be made for it. The rafter legs of the bulbous dome have a specific shape called “Zhuravets”. As a rule, a layered rafter system is used in an onion dome. Additional rigidity to the rafter legs is given by struts and braces, which are installed at the points of greatest loads in order to prevent the destruction of the dome structure.

"Zhuravtsy" are cut according to special patterns from wooden boards with a thickness of 40 mm; for this purpose, it is allowed to use a double board of a lesser thickness. The rafter legs rest on a central pillar, which also serves as the basis for the installation of the cross that crowns the head.

If it is planned to cover the dome with metal, then a crate is mounted along the "Zhuravtsy", which has a step, as a rule, 30 cm. But often the dome is covered with a scaly roof, this is one of the most laborious methods, since for each "scale" an additional circle is installed, which will support it.

Often during the restoration of wood churches, the dome is covered with an aspen ploughshare. To do this, each plank is gently bent in order to create an exact repetition of the onion design. The ploughshare layers are mounted on the roof so that water cannot flow between the rows.

Making the roof of domes is a rather painstaking and laborious work. In general, in the field of roof repair, work related to domes is, as a rule, rare, but very difficult work. Domes are made in different ways - 1 - directly on the roof, already from the finished roofing material; 2 - the roof of the dome is made on the ground, then it is installed in place; 3 - the roof of the dome is first made of ferrous metal, then the "golden light" type is sprayed and then the dome is put in place. The roof of the towers is usually done on the ground, after which the tower is erected in place. Usually, roofing with blocks and scales is used, less often folded roofing is used.

What explains the evolution of the architecture of domes in Russia, from helmet to bulbous? There is a version that this is the influence of Byzantine icons. It was on them that the domes of the buildings of Heavenly Jerusalem were bulbous. It is also known that the Byzantine dome structure was not changed. In our country, from a certain period of time, the domes acquired a bulbous appearance.

I must say that Orthodox churches, unlike Catholic ones, were erected in accordance with Orthodox symbols. Catholics paid tribute to the architectural style in the construction of churches.

Domes always complete the construction of all Orthodox churches. The architecture of the domes symbolizes the spiritual sky.

Exclusive products. Domes

Today the roof is not only a reliable protection of the building from external influences, but also an important decorative element of the building. For many years, our company has been building its various types, among which domed roofs take an important place. They are used in domed construction as well as for round buildings. Since the curved roof of the building is five times larger than its walls, this structure is original in appearance. This architectural feature is due to a number of "pluses" of such a building.

Advantages of a home with a domed bulbous roof

· Since the structure has no load-bearing walls, it is very strong and stable.

· Due to its streamlined shape, the roof does not become an obstacle to strong air currents, therefore it preserves the integrity and strength of the structure.

· Due to its geometry, such a covering is unpretentious in maintenance. Precipitation does not accumulate on it.

· A spherical roof has a large volume with a small area. This makes it possible to save time, material and labor resources.

Making domes of churches is one of the directions of our activity. Today we work both on classic projects and make models according to the customer's sketch. This is a very time-consuming process, but having extensive experience in this area, we are ready to make a copy of any complexity, as well as guarantee high quality work.

For example, if you decide to make a dome for a chapel, our staff can provide existing designs or implement your idea. Depending on the size of the product, it can be made in the workshop and then installed as a whole (small in diameter). And it can be performed in sections, which are then mounted one by one (for large sizes).

Roof decoration, exclusive

The exclusive elements in the roof equipment are of no small importance. They have both practical and aesthetic value. These can be unusual snow barriers, hoods and chimneys, skillfully created weather vanes, etc.

When designing domes and other structures, the following are taken into account: climatic zone, atmospheric conditions, wind loads, compatibility with embedded parts, possible methods of transportation and installation.

All work is performed by a team of qualified specialists who have undergone special training and certification.

Such a roof has many advantages, in particular, it can be almost completely glazed with PVC windows, and you will not have problems with clearing it from snow. In addition, this structure has excellent resistance to wind loads. In a word, an interesting option for a home greenhouse device, for example.

Onion roof device

Semicircular types of truss systems will be incomplete if you do not consider the device "onion" roof. This roof shape is a distinctive feature of Orthodox churches and cathedrals. It is difficult to assume that someone will use this form for their own buildings. But if we take into account the fact that not all churches in Russia are being restored by construction companies, especially in distant villages, then additional knowledge of how to make the truss system correctly will not be superfluous.

If the dome is no more than 3 m in diameter, then its frame can be made of wood. The specific shape of the rafter legs of the bulbous dome is called "Zhuravets". In fact, we are dealing with a layered rafter system. The braces and struts installed at the points of greatest load give additional rigidity to the "Zhuravtsy" in order to prevent destruction of the dome structure. "Zhuravtsy" are cut according to special patterns from boards with a thickness of 4 cm, for this purpose a double board of lesser thickness can also be used. Zhuravtsy lean on the central pillar, which also serves as the basis for the installation of the cross crowning the head. Installation options can be seen in the photo.

If the dome is covered with metal, then a lathing with a pitch of 30 cm is arranged along the Zhuravians. But it happens that the domes are covered with a scaly roof, this is the most laborious method, since for each "scale" an additional circle is mounted that supports it. And during the restoration of wooden churches, the domes are covered with an aspen ploughshare. Each plank is gently curved to closely follow the design of the onion. The ploughshare layers are placed on the roof so that they do not allow water to flow between the rows. A bulbous roof is a rather rare type of roof that has an almost spherical shape. Most often, such roofs are decorated with Orthodox churches, although there are many cases when an individual developer also uses this form of roof in the construction of a residential building. The opinions of historians are divided as to where the bulbous roofs came to us, some argue that this is the heritage of Muslim temples, while others are convinced that this bulbous shape of the roof is an exact copy of the shape of the tents of ancient Russian architecture.

Since the specific shape of the roof limits the choice of material, such roofs are usually covered with a copper block.

In the construction of Orthodox churches, this form is used for a reason, the main factor why the architects chose this particular form of the roof is that it resembles a lighted candle in all its appearance.

The roofs are curved. Bulbous heads. Bulbous domes, depending on their size (diameter), were made as follows: - small (diameter less than 60 cm) - from a solid log, which is a continuation of the axial pillar and at the same time a stand of the cross (photo 28). - Large (diameter more than 60 cm) - frame structure, including the following elements - cranes, circled, crate, covering of heads (wooden ploughshare)). Zhuravtsy at small-diameter chapters could each be made from one solid board, with large diameters they rally from several boards. The number of cranes also depends on the size of the head and, as a rule, ranges from 8 to 24 per head. For an example of constructing a chapter form when it is lost, see fig. 16. Zhuravtsy directly form the head, its contour, they are installed on the circle with their heels, and are cut (or nailed) with the upper ends into the axial pole-mast. Zhuravtsi are made from a board according to a template. They are connected to each other by sheathing boards, worn at the ends and along the outer surface to create a rounded head. To fasten the lathing, the outer 21 edge of the Zhuravets is cut on two sides (on the mustache). Usually, the thickness of Zhuravets' boards is 50-60 cm. The lathing is made of wide - up to 25 cm and thick - 5 cm, unedged hewn boards. They are tightly pressed against one another, forming a continuous flooring.

A layer of birch bark is lined along the leveled surface of the lathing, with an overlap of the overlying sheets on the underlying ones. The roof itself is laid along it - a ploughshare. When restoring the monument, one should strive to make the most of the surviving elements of the chapters, the zhuravtsy and the circle, with this, first of all, we will preserve the exact dimensions and shape of the structure with all its nuanced features. Restoration of these elements can be carried out by installing crowns, dentures on wooden nails or using additional fasteners. Ploughshare. The most common material for making a share is aspen. However, in a number of cases, at some sites in various regions of the North of Russia and Siberia, a share of pine, larch and, less often, wood of other tree species was found. For the manufacture of a ploughshare, healthy logs are taken, which are sawn into logs equal in height to the required length of the ploughshare. The sizes of plowshares vary considerably depending on the parameters of the head or drum of the heads they cover. The larger the head, the larger the share is used for covering. Its dimensions are in the range of 16-22 cm in width and from 25-45 cm in length, with an average thickness in the lower part of not more than 3 cm, the upper edge of the plowshares is almost absent. Large and small plowshares are rare; the most common plowshare size is 20-40 cm. The plowshare is hewn out with an ax according to the dimensions specified in the project or determined from surviving historical samples. When making a ploughshare, it should be borne in mind that the old masters for the main part of the surface of the head made a ploughshare, as a rule, of one 22 size, but of different curvature in height and width, depending on the location of the ploughshare.

When installing the share in the lower part of the head, expanding towards the top, the plowshares are suspended along the edges in the lower part, for the middle part of the chapter they remain as they were made, and in the upper, tapering part of the chapter they are again suspended along the edges, but already at the top. Therefore, in the tapering part of the head, the joints of the overlying plowshares may not coincide with the axes of the underlying ones and are located rather freely, but so that these joints still overlap with the upper plowshares. For the narrowest, upper part of the chapters, the size of the share is changed slightly, narrowing it, but so that there are no more than 10 pieces of share in the top row. A common mistake when carrying out restoration work on the chapters is the production of the same number of plowshares for all rows, with a change in their width, with their unjustified grinding in the upper part of the covering, and the resulting orderliness of the plowshare cover destroys the plasticity, liveliness and naturalness of the form characteristic of traditional folk architecture. The ploughshare is fastened at a distance, with the overlap of the lower row by the upper one by about 0.5 plowshares length.

Plowshares are fastened with one or two nails, closed by the overlying plowshares. The ploughshare is found in several types according to the form of processing of the lower part - crenate, scaly, iron. The crenellated ploughshare pattern is the most widespread and most ancient. There are examples when the temples of the XVII - XVIII centuries. during the repairs of the XIX century. replaced the crenellated ploughshare with a scaly or ironed one (Odigitrievskaya church in the village of Kimzha, Arkhangelsk region). A definite dating feature for a share is the ratio of the height and width of the town steps. The most ancient plowshares are characterized by elongated, more elongated vertical sections of the elements of the town cutting. 23 Kruzhala, which are the base of the head, were made of thick boards (50-80 mm), as a rule, composed of four elements, and for large heads and more, they ... To install the feet of the cranes, grooves were selected in them. The outer edge was circled and hung on a mustache for laying and attaching the epanchi ("tear belt", "collar")

Church domes are a complex type of architecture, it is almost impossible to mount it for a non-professional; this is not a rafter system for metal tiles or other roofing material for a gable roof of an ordinary house.

If the dome is more than 3 m in diameter, then metal is used for its frame. Here, the cranes with the support post will be fastened with spacers, also made of metal. The crate will be metal strips, which are mounted with a step of 0.4-0.5 m. Such domes are covered with a metal folded roof. Often metal sheets are in the form of flakes, the seams of which are soldered during installation.

We wrote a lot about the types of rafter system, gave overview descriptions of the calculations that must be carried out first if the roof rafter system is being built with our own hands. First of all, we described the device of rafter systems for single-pitched, gable, hip or hip roofs. But in individual construction, there are also conical and semicircular roofs. As the topic of this article, we have chosen an overview of rafter systems for such not common roofs.

Conical bulbous roof device

A conical roof can be made over a circular or multi-faceted structure. The rafter system scheme assumes a layered type of rafters. Since they require supporting elements - girders, a circular girder will act as the upper support, which is fixed on the central pillar in such a way that the uppermost point of the turret cone is not loaded. The second support will be the same ring Mauerlat, which fits along the turret wall. The design of the ceiling beams must be designed for a concentrated load where the center pillar will be installed. An annular ridge girder is attached to the central post with braces. All the nodes of the truss system require careful calculation, if you do not feel confident in yourself - it is better to order a calculation from a construction company!

For those who are going to use wood, we will say that it is best to order elements of the rafter system from glued laminated timber, especially when later using natural tiles as a roofing material. Since this is a very heavy material - one square meter of such a roof will weigh at least 40 kg, wooden truss systems for it must have increased strength.

The number of rafter legs, which are the stiffening ribs of the conical roof, will be determined by the section of the material used and the required distance between them.

As a roofing material for conical roofs, in addition to natural tiles, it is good to use bituminous shingles, wooden shingles or metal. As an example, we give a photo of the rafter system of a wooden house with a conical turret. It is irrational to use any corrugated sheets on such a roof - a lot of material will go to waste and the joints will be a constant "headache" for the owner, and such a roof will simply look ugly from the outside.

Dome roof device

Unlike a tapered roof, which is built using a layered rafter system, a domed roof has a hanging rafter system. A conventional three-articulated arch, which, in fact, are hanging rafters, rests on one end on a Mauerlat laid along the wall, and on the other on a support ring, which is mounted at the top of a pillar installed in the center of the structure.

If you like such structures, then the construction and design of the rafter system for it will require good technical knowledge in the field of classical "Strength" and "Theoretical Mechanics". Do not own enough of either one or the other - it is better to order a calculation from a construction company. They will count, and you can build on your own.

Consider, as an example, the drawings of a wooden dome:

A) Diagram of the loads that act on each arch of the hanging rafters,

B) Scheme of fastening the arches to the central support and the Mauerlat, as well as the design of the ventilation lamp above the upper support ring,

C) View of the dome from above,

D) The design of the locking hinge at the top of the dome,

E) Top view of the ventilation lamp.

The semicircular structure of the dome is obtained due to the annular lathing, which is mounted on additional posts, resting against the tightening of the hanging rafter arches.

Another method for constructing the dome was proposed by the American architect R.B. Fuller, he presented the dome as a structure formed by triangles. His project is called "Geodesic Dome". Despite the fact that this design was presented back in 1951, it did not become widespread. Most likely, due to the complexity of the calculations and the unusual appearance.

Fastening the rafter system in a geodesic dome can be of two types:

· Connector, when triangles are assembled from pieces of timber and special locks-connectors directly above the walls of the house.

· Connectorless, when triangular panels are made in advance and are assembled on site into a common structure.

DIY step-by-step instructions for making a mobile geo dome

DIY geodesic dome

Good afternoon! This article will be useful for everyone who is interested in a geo dome, and who wants to create this amazing structure with their own hands. In this article, we will not go into the general theory of geo domes, since this is a rich topic covered in other articles. Below are specific instructions on how to make a small mobile geo dome. Such a dome will be an ideal solution for all travelers and lovers of living in nature, suitable for a summer cottage or a children's house. This dome is a versatile mobile tent, compact for transportation (suitable for any car), quick to assemble (2-3 hours), very durable and resistant to natural elements. And also this house is round and harmonious. People say that due to its synergistic (geodesic) structure of the frame, the geo dome has a beneficial effect on the surrounding space and harmonizes it. We have been convinced of this many times by experience. Having installed a stove in such a house, you can safely live in it until late autumn. There are options for wintering, but they require insulation.

Many photo materials for this article were collected from various sources, for which many thanks to their creators. Also, special thanks to our Latvian friends who inspired us to create such an instruction.

So, let's begin!

This is the kind of geodesic dome you should end up with.

Dome diameter: 6.2 meters

Dome height: 3.65 meters

Parts QTY: 165

Number of standard sizes: 3

Area: 30 sq.m.

Number of bolts: 61

Bolt size: М8х60

Selection of frame material

A convenient and budget material for the frame of a geodesic dome is a steel pipe (electrowelded). A round tube 25x1.5mm is suitable for our dome. You can buy such a pipe at the nearest market or metal warehouse. Typically, pipes are sold six meters long. For the convenience of delivery, you can saw them at 3 or 1.5 meters.

So we need 252 meters of pipe (42 pipes of 6 meters each). The cost is about 6,000 rubles.

Tool selection and workspace creation

To make the frame, you need the following set of tools:

Manual grinder with discs for metal (or cutting machine)

Hand drill (or drilling machine)

Drill bits for metal (diameter 9mm)

Hand press

Vise

Work table (minimum 1.5 meters long)

Pipe cutting

Selection of hand press and preparation of the workplace

You can see some models of the hand press. If you have a friendly metalworking facility, you are lucky).

For fast and accurate production, you will need various accessories and devices that help and accelerate the process. Here you can show your divine intelligence or use ideas that have already been invented.

Next stages of production

Flattening the pipe ends (in one plane !!!)

Drilling

Bending the ends by 11 degrees relative to the entire pipe (this is necessary to "round" the frame into a dome)

Tip diagram:

The first end of the pipe is flattened arbitrarily, but the second end must be flattened in the same plane as the first end. Therefore, craftsmen use a simple device "slit", clamping the first flattened tip in a certain plane. At the same time flatten the other end in the same plane. After flattening, it is recommended to process the ends with a file or balkar (remove sharp corners and burrs).

For drilling holes, you can make a small device shown in the photo below. In this case, the device helps to secure the pipe. During this operation, the exact distance between the centers of the holes is also checked (with a tape measure or a mark on the table).

After drilling all the holes, you need to bend the flat ends of the pipe 11 degrees relative to the pipe. To do this, you can use the tool below. In this case, a line is drawn on the table, corresponding to 11 degrees, which is a mark to which you make a bend.

After all the operations, you should get something like this:

Painting elements

There are many tips in this matter that you can find on the Internet. After painting, it is recommended to mark all elements with a color code for ease of assembly.

Fasteners

M8 bolt, 50mm long - 65 pieces

Washer М8 - 130 pieces

Nut M8 - 65 pieces

Assembly

You will need 2-3 people, M8 wrenches (or wrench) and a small stepladder (or tour). The first time it will be more convenient to collect from the bottom up. Use a color scheme for assembly. Collect the dome in an orderly, spiral pattern !!! Those. unfold and secure the bottom ring first, then attach the next row to it, connect the row. Continue in the same spirit, collecting each row in order.

In order to keep the posting not too long, instructions on how to make a dome shell will follow in the next post.

We wish you successful creativity !!!

In recent years, domed houses in our country have moved from the category of exotic to the category of unusual buildings. Their owners are no longer perceived as developers who simply decided to stand out against the background of typical cottages, but as people who made an informed choice of such a design.

But the mass distribution of domed houses, as usual, is hindered by stereotypes and a lack of practical information on the design of such structures. Therefore, in this article we will tell you:

- What is the difference between a stratodesic domed house and a geodesic one.

- How to build a domed house yourself.

- How to build a domed house without using connectors.

- How much does it cost to build a domed house?

The difference between a stratodesic domed house and a geodesic one

As practice shows, people who first saw or learned about domed houses are most often divided into two categories. These are those who unconditionally take this form of the house and, we note, the way of life, and those who consider such structures a fad or, as an option, a house not for permanent residence, but a summer cottage "not like everyone else."

We will not go into the details of discussing the advantages and disadvantages of domed houses (and they, like any construction technology, have them) and concentrate on practice. So, there is a builder who wants to build a domed house. Where to begin? An excellent example of a competent and thorough approach is the story of a portal user with a nickname Rustad.

Rustad FORUMHOUSE user

I decided to build a domed house of a relatively small area, about 100 sq. m, near St. Petersburg. The plot is inclined. The house will be mainly used in summer with infrequent visits in winter. I will build a geodesic dome house using connectorless technology. Such a structure is an accurate mathematical model. It is impossible to build it without calculation and design, because the error in assembling the frame and in the manufacture of parts should not exceed 1 mm. If you do not follow this rule, then the frame will "go away" when jambs accumulate.

Before we talk about the nuances of designing and building a house, presented in the photo below, we will answer the question that is one of the first to arise before any person who wants to build a domed house.

What is the difference between a stratodesic domed house and a geodesic one? Without going into a detailed description of the technology, let's say that the key difference lies in the way the frame is erected.

Stratodesic dome It is erected from racks, for example, made of bent-glued wooden beams, and the stages of its assembly are in many ways reminiscent of conventional frame construction technology.

The peculiarity of this technology is its resistance to vertical loads and the possibility of using standard windows and doors in the construction.

Geodesic dome erected in a slightly different way. First, individual sections are made, for example in the form of triangles, which are then connected to each other step by step.

When assembling the edges (sections) of a geodesic dome, a connector technology can be used (for example, using a metal connector).

Or (less common in Russia) connectorless technology.

Rustadsettled on the last option and, as we said above, started with the development of the project.

Rustad

Building a domed house without a project or by scrawling something with a pencil on a piece of paper is a futile exercise. From the experience of my acquaintances, I can say that this always leads to only one thing - alterations and endless restructuring of what happened. It is also not a panacea - to outsource the project to a designer.

A designer can draw beautifully, but from a practical point of view, what he has created is often simply impossible to bring to life. A house should be designed by a person with a specialized education, but even a design engineer may not take into account the position of the building on the site relative to the cardinal points, the wind rose, and the size of finishing materials. therefore Rustad, having two free months at his disposal, he sat down to design a domed house, and that's what he got in the end.

Note that the project has been modified several times during this time, taking into account the recommendations of experienced builders, the availability of materials, the peculiarities of the arrangement of furniture and the introduction of wishes from the household.

Stages of construction of a geodesic domed house

Having completed the design stage of the domed house, Rustadmoved on to its construction. Here are a few of the user's recommendations regarding the organization of construction.

Rustad

I wanted to build the house in the shortest possible time, so I attracted assistants - one person who is well versed in the features of frame construction and an auxiliary. I will say right away, yes, these are unnecessary expenses, but if I were to build a house alone, it would take me 3 summer seasons. At the same time, it would most likely not have been possible to achieve high-quality work. Because purely physically, it is impossible to hold the nodes (frame edges) alone and at the same time fasten them to each other. During assembly, you have to pull or bend something all the time. The second and third pair of hands are vital. Otherwise - the accumulation of errors from row to row and, as a consequence, a "jamb" with the upper contour.

According to the user, he supervised the construction, and his personal - physical contribution is about 30%. The experience of the master (to avoid mistakes) of the skeleton builder was also useful. The speed of the contour assembly has also increased significantly, since 2 people do the work 4 times faster than 1, and 3 people “crank” the same amount of work 8 times faster.

Therefore, the entire construction is divided into a series of successive stages, each of which requires careful control.

1. Erection of the foundation for the domed house.

The plot is located on a slope. The angle of inclination is about 12 degrees. As a foundation Rustadchose a pile-screw. The pile field consists of 24 piles with dimensions:

- pile diameter - 108 mm;

- pile length - 2.5 m.

The piles were twisted in 2 days, being carried until the night. The user notes that, having trusted the foreman of the workers, he himself did not mark the pile field.

As a result: several piles were not where the house nodes are. To correct the error, the “16th” channel had to be welded on.

2. Manufacturing of the frame: ribs, posts and rafters.

For the frame, we purchased a winter forest and pre-cut all the blanks to size on a miter saw, in accordance with the project.

It took the user 4 days off.

3. Assembling the domed house.

Construction of the house began in April. The weather was, to put it mildly, "not flying": it rained, then snow, then wind.

The erection of the domed house began with the installation of a riser (cylindrical base).

The riser was recruited from triangles to make the house look like a whole.

At this stage, the question arose of how to make a takeout under the terrace. The user did not want to twist the piles for each log - it would have been one continuous pile field. It is economically unprofitable, and besides that, the terrace would look ugly.

Rustaddecided to make a terrace in the form of a "balcony" - a departure, which is a continuation of the floor of the first floor. It remains to choose a material that will withstand such a load.

Rustad

When I took up this issue and turned to firms, they recommended me to make a take-out of I-beams glued wooden beams. Comparing these beams (18 mm thick OSB wall) withLVL timber with a cross-section of 51x300 mm, I did not see any special economic benefits in purchasing an I-beam, but to doubt the strength and bearing capacityThere is no need for LVL timber. He put it.

Having mounted the logs, a temporary floor was laid on them from boards, because weather conditions did not allow to do normal.

It took 2 days to assemble the dome (in snow, strong wind and rain).

An important nuance:to fasten the ribs and beams together, the user used constructional screws 6x140 mm.

Unlike conventional self-tapping screws (especially the so-called hardened "black" ones, which cannot withstand dynamic loads and break), the structural self-tapping screw can be bent into an arc, and it will not burst. A special notch cuts through, and does not push apart the wood fibers, so the self-tapping screw can be screwed into a knot or into the edge of the board, and it will not crack.

Also, the self-tapping screw is stronger than usual, and the "asterisk" head does not allow the bit to break off and cut off edges, which simplifies screwing.

The assembly of one assembly of six ribs requires 12 pcs. self-tapping screws.

Utilities - water pipes, electric cables laid in the floor.

The electrical box was also assembled in accordance with the project at home and placed in the "plinth".

The next stage is covering the assembled dome with a moisture and windproof membrane, with obligatory gluing of overlapsspecial tape. Stuffing the crate for the ventilation gap. Installation of OSB (bases for flexible shingles).

The "pie" of the dome practically repeats the "pie" of the roof for installation of a soft roof.

An important nuance:the covering of the dome was made of patterns (triangles) from OSB-3 sheets, 18 mm thick, with dimensions 1220x2440 mm.

The cladding was nailed with 6x60 mm brushed nails.

Rustad

Such a nail holds very well. You can pull it out only with "meat", but it clogs faster than twisting the screws.

Having made the outer contour, the builders began to warm the floor. Ecowool was blown into the floor with a layer of 30 cm, using a homemade installation based on a garden vacuum cleaner and a plastic barrel.

After warming, the floor was covered with sheets of moisture-resistant GSP (gypsum-particle boards) 12 mm thick, laid in 2 layers.

Having mounted the base, we switched to wall insulation. For this, a synthetic non-woven material (insulation) 5 cm thick was used, laying it in 3 layers.

Rustad

It is pleasant to work with this type of insulation. It does not prick, is not afraid of moisture, lightweight. It is only difficult to cut with a knife, it is better to use scissors or a special electric carpet cutter. And I will add: it is better not to put heavy objects on the insulation, and also not to store the rolls in height. The insulation may not recover its shape after removing the load. It is better to act according to this algorithm - we brought it in and put it right away.

After insulating the walls, a vapor barrier was pulled over the frame and everything was also sewn up with gypsum-particle boards, but only 10 mm thick.

At this stage, the house has already acquired a finished look. After the construction of the partitions, the installation of engineering systems and finishing processes began.

This includes the following works.